Snap-action thermostat with duplex structure

A sudden jump thermostat and thermostat technology, applied in the direction of thermal switch parts, etc., can solve the problems of part size error, arcing, shortening the life of contacts, etc., achieve accurate positioning and clamping, and reduce production Difficulty, easy and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail by the following examples.

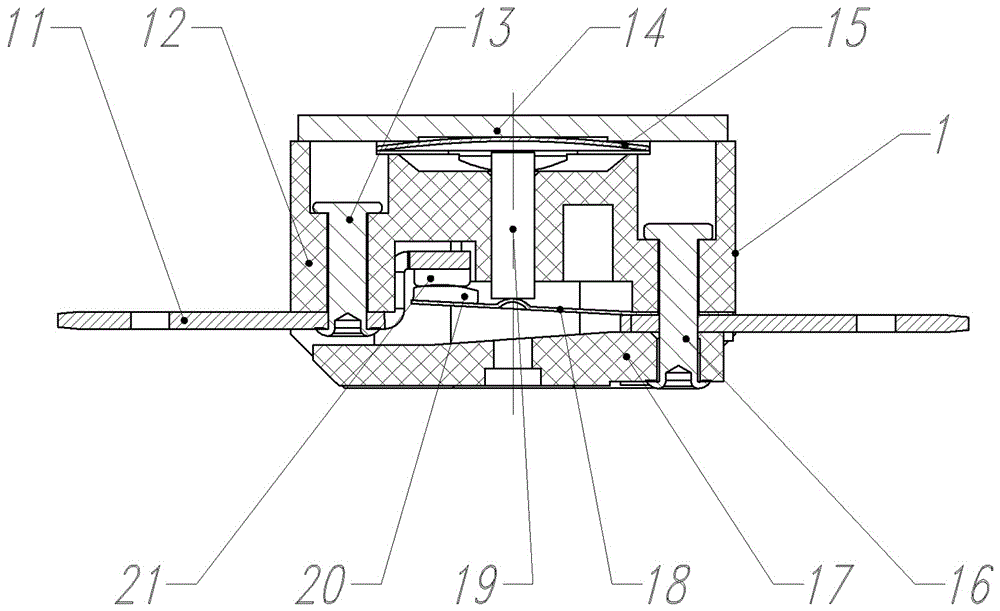

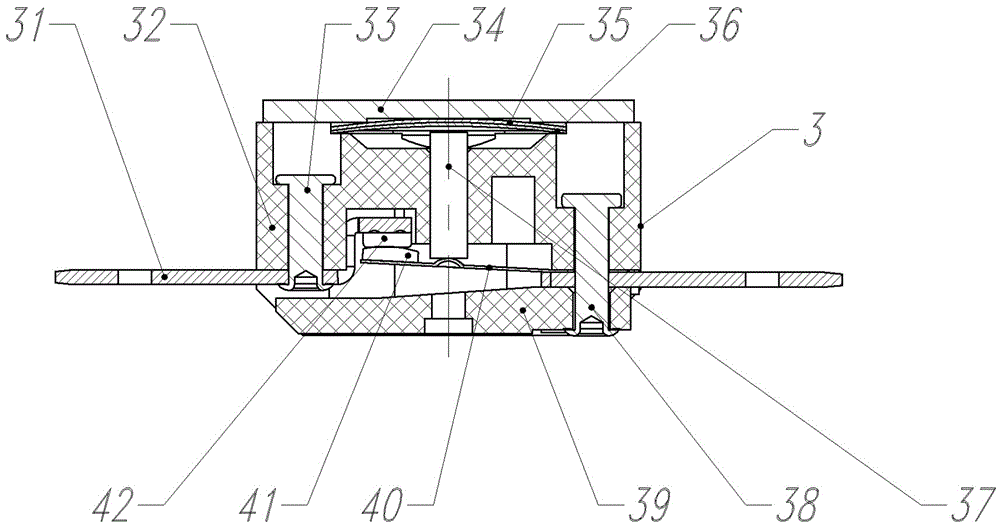

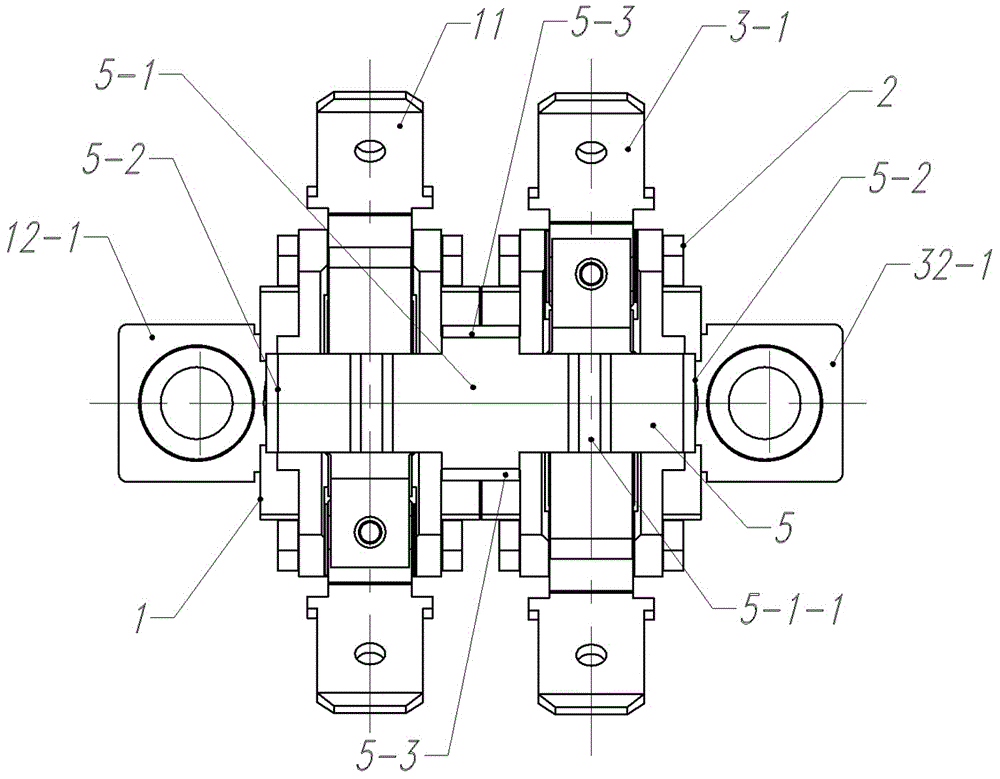

[0019] see Figure 1-5 As shown, a double-connected snap thermostat is composed of a temperature control snap thermostat 1, an over-temperature protection snap thermostat 3 and a stainless steel elastic clip 5. The temperature control jump type thermostat 1 is sequentially composed of the first cover 14, the first bimetal disc 15, the first action rod 19, the first fixed contact 21, the first moving contact 20, the first 1 The movable contact bracket 18, the first insulating shell 12, the first insulating cover plate 17, the first terminal 11 located on the front and rear sides, the first long rivet 16, and the first short rivet 13 are assembled. The over-temperature protection jump type thermostat 3 is sequentially composed of a second cover 34, a second bimetal disc 35, a stainless steel action piece 36, a second action rod 37, a second fixed contact 42, The second moving contact 41, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com