Method and device of optimizing production assembly line work and production assembly line

A production line and assembly line technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problem of no "work standard time", and achieve the effect of accurate grasp and elimination of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

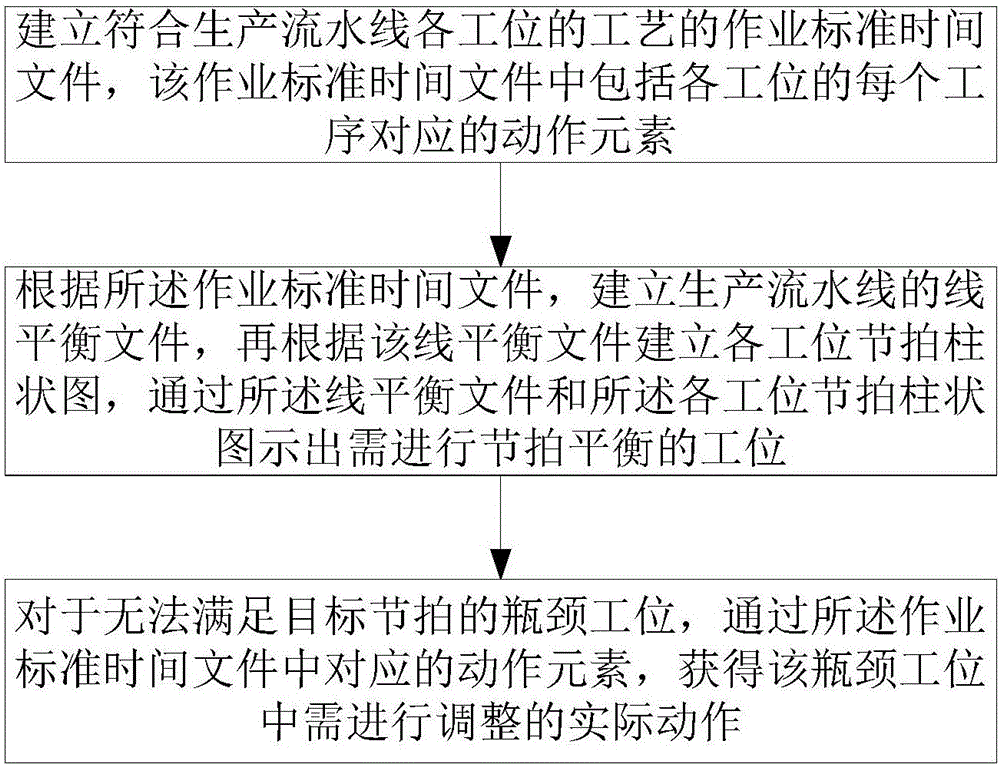

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] In the present invention, relevant terms are explained as follows:

[0030] 1. Operating standard time: It refers to the time required for operators who have reached the average level of operating proficiency and skills to produce a unit of products of specified quality at a normal speed according to specified operating conditions and methods.

[0031] 2. Line balance: It refers to the technical means and methods to average all the production processes and adjust the workload to make the operation time as close as possible.

[0032] 3. Beat: It refers to the interval between the continuous completion of the same two products (or two services, or two batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com