Downhole water level monitoring terminal

A water level monitoring and terminal technology, applied in liquid level control, drainage, non-electric variable control and other directions, can solve the problems of weak anti-interference of the control system, unsatisfactory system operation, and complicated debugging, and achieve reasonable technical measures and convenient installation and debugging. And the effect of post-maintenance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

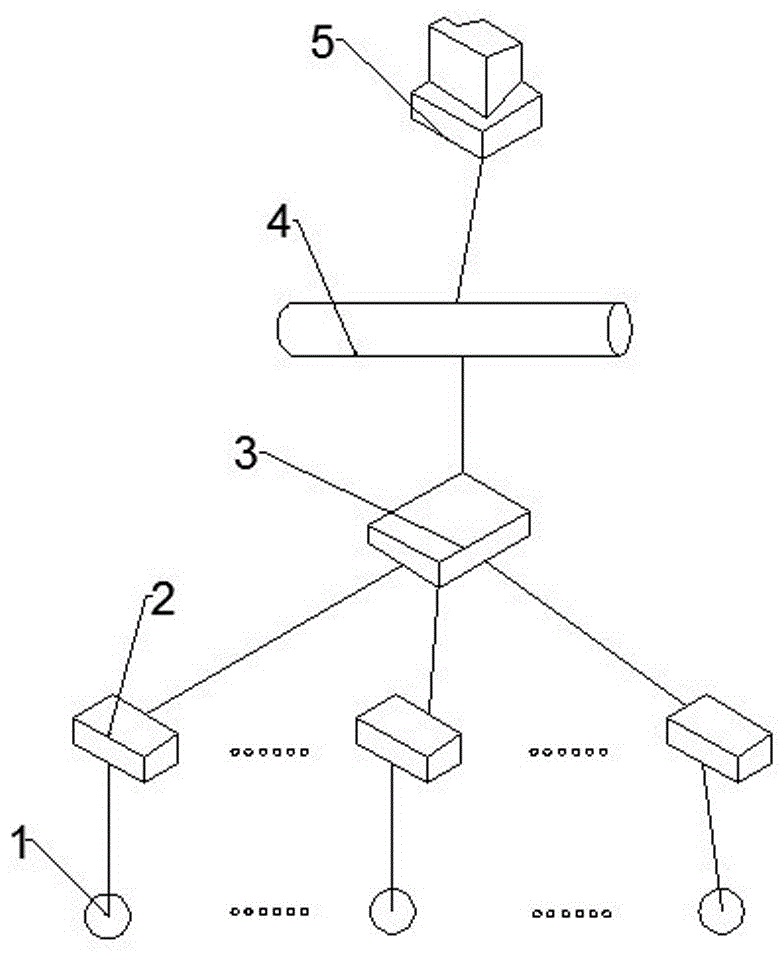

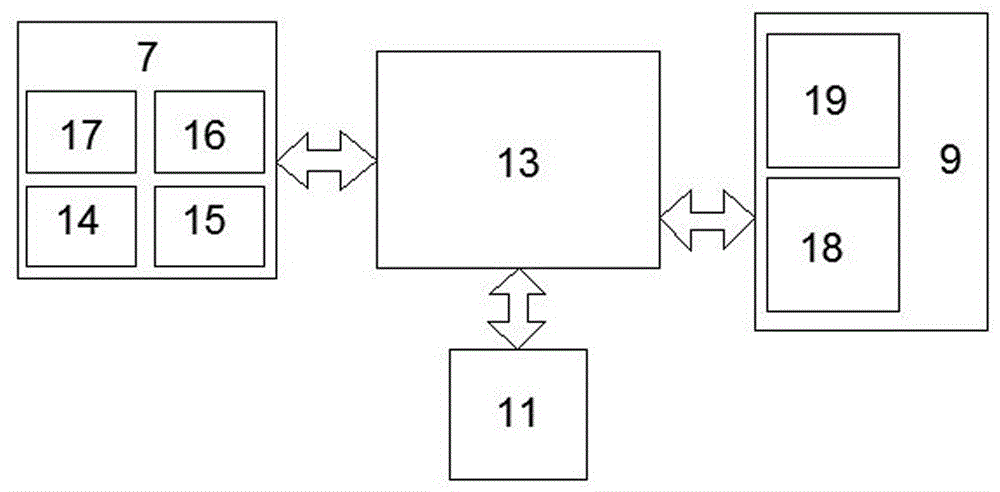

[0015] see Figure 1 to Figure 3 , the present invention provides a technical solution: an underground water level monitoring terminal, comprising several water level sensors 1, the water level sensor 1 transmits the water level signal to the concentrator module 3 through the sensor control module 2, and the concentrator module 3 transmits the water level signal through the Ethernet The network 4 sends the water level information to the upper computer 5, and the sensor control module 2 adopts the NuMicroM054LBN microcontroller 6 as the main controller. The NuMicro M054LBN microcontroller 6 has enough I / O ports, which can be used for external expansion of various sensors. The main controller is connected with a minimum system module 7, a communication module 8, a human-computer interaction module 9 and a peripheral sensor module 10. The communication module 8 is composed of an RS-485 interface 11 and a GPIO interface 12. The concentrator module 3 adopts The LPC1768 microcontrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com