Wire cable breakpoint position detection method

A technology of wire and cable and detection method, applied in the field of wire and cable breakpoint position detection, can solve the problems of large distance error of breakpoint position, low detection efficiency, detection failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a method for detecting the breakpoint position of electric wires and cables, which can overcome technical problems such as electromagnetic shielding and inaccurate capacitance calculation, and accurately find the breakpoint position of the cable.

[0028] In order to better understand the above technical solutions, the present invention will be further described below in conjunction with specific embodiments in the accompanying drawings.

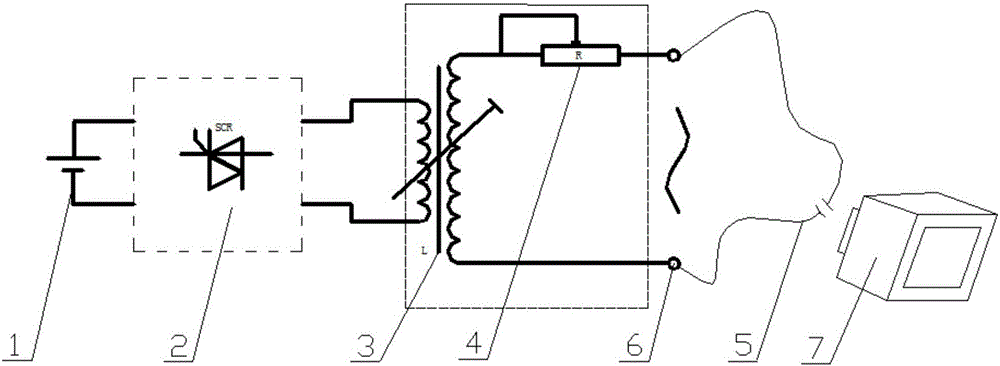

[0029] Such as figure 1 As shown, a method for detecting a breakpoint position of a wire and cable includes: providing high-voltage alternating current; connecting the high-voltage alternating current to the wire and cable 5 under test; observing the entire wire and cable 5 under test with an infrared thermal imager 7, The position of the obvious bright spot found in the imaging of the imager 7 is the breakpoint.

[0030] The inverter device includes a transistor oscillator 2 that can convert direct current int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com