Cylinder special-shaped buckling detection device and recognition method

A detection device and identification method technology, applied in the detection field, can solve the problems of difficult to achieve measurement accuracy, high safety requirements, and high detection costs, and achieve the effects of improving work efficiency and safety level, improving measurement accuracy, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

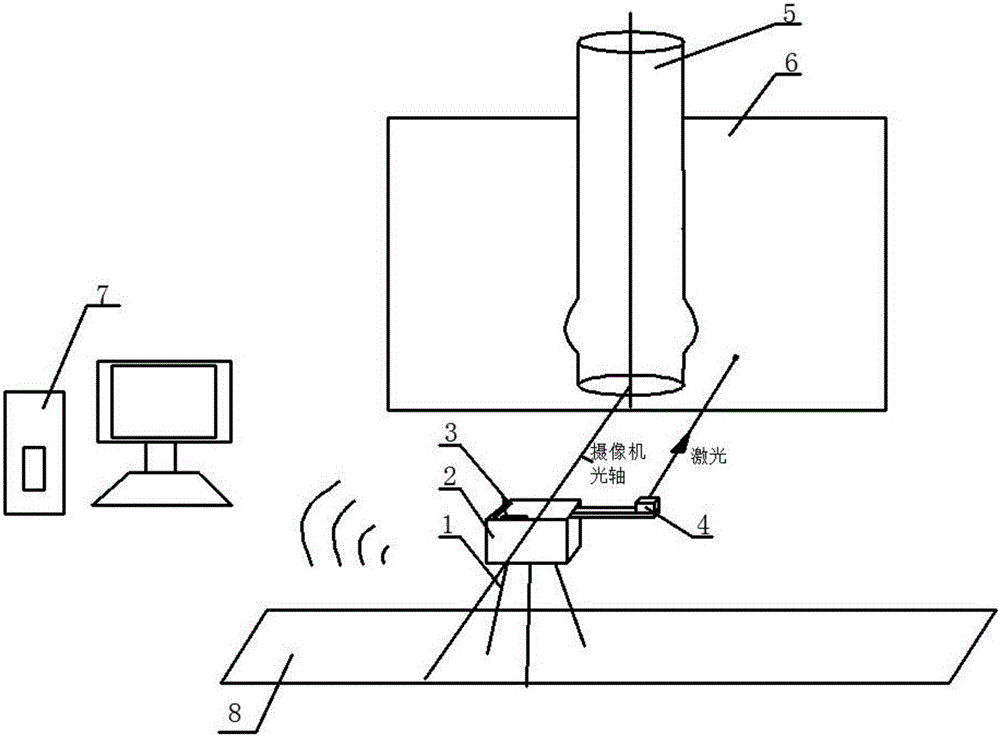

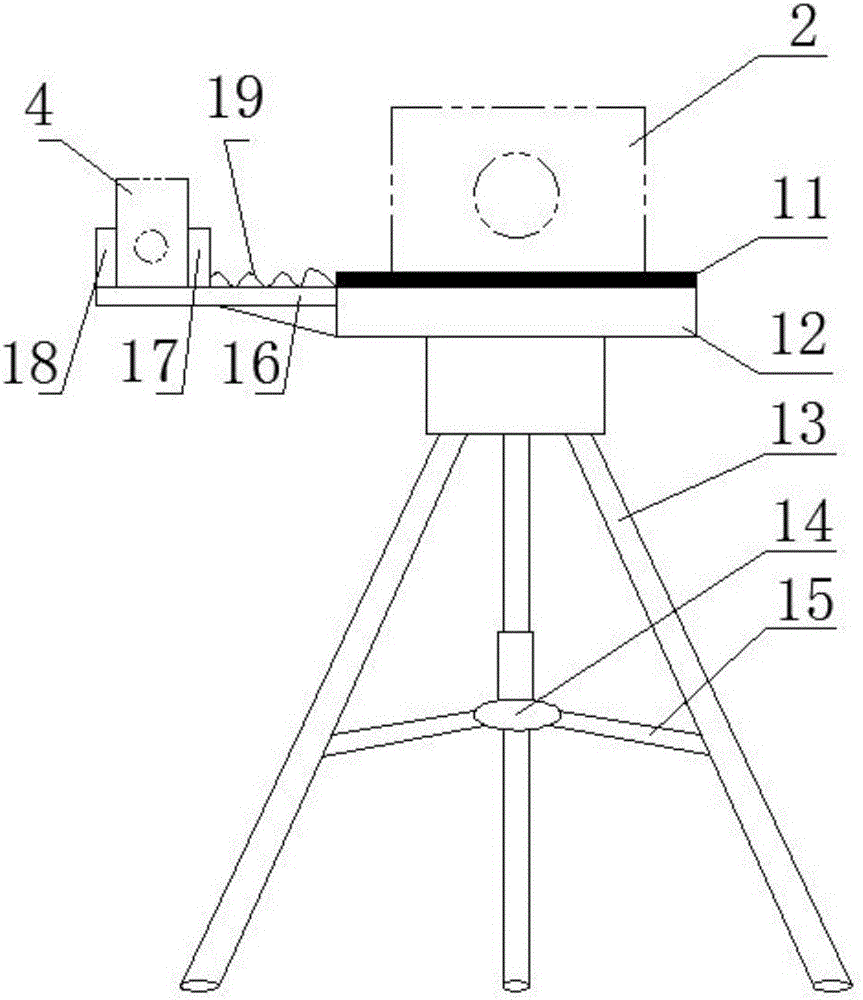

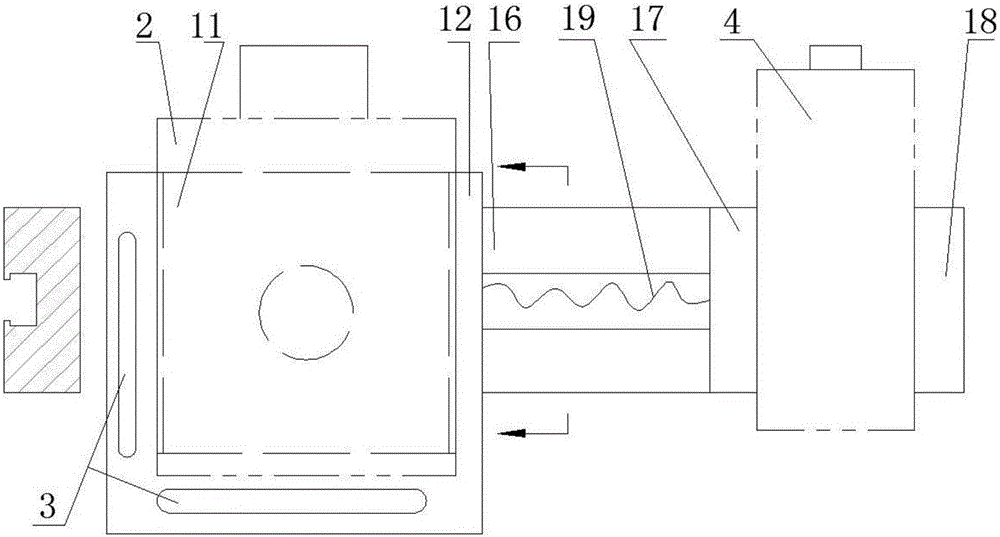

[0053] The device structure of this embodiment is as figure 1 , figure 2 and image 3 As shown, it includes a tripod 1, a camera 2, two levels 3, a laser rangefinder 4, a steel tube concrete column 5, a white baffle 6, and an electronic computer 7 for storing images acquired by the camera 2 and performing digital image processing.

[0054] The tripod 1 includes a tripod 13 and a tripod base 12. The three supports of the tripod 13 adjust the opening angles of the three supports through the connecting rib 15 and the central axis slider 14, so that the height of the camera 2 can be fine-tuned and placed stably. Tripod 1; the top of tripod support 13 is tripod base 12, and tripod base 12 is provided with slot, is inserted with flashboard 11 in the slot, camera 2 is connected with flashboard 11 by screw thread; The external fixing of tripod base 12 Connect with outrigger 16, be used for installing laser range finder 4, have groove on the upper surface of outrigger 16, groove and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com