Insulating digital real-time monitoring load-bearing device for live working

A technology of real-time monitoring and live working, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as difficult control of construction personnel and equipment damage, so as to improve construction safety, increase service life, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

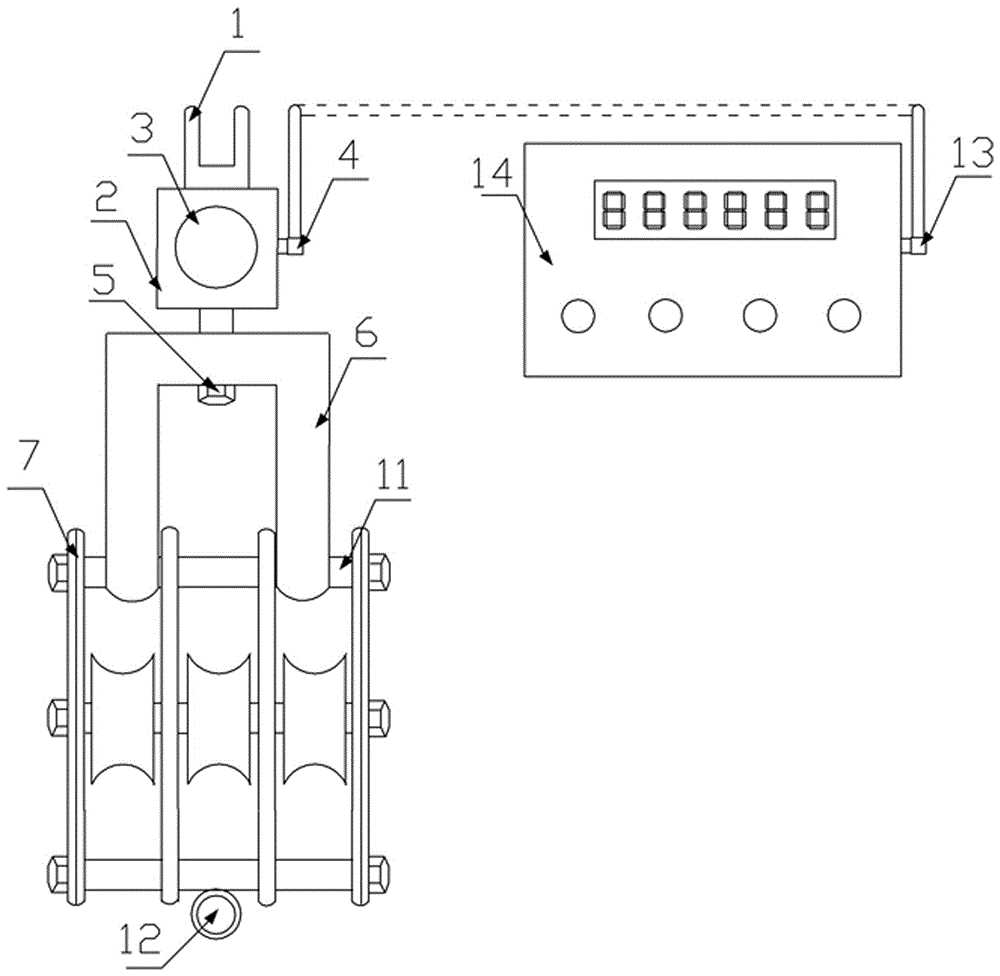

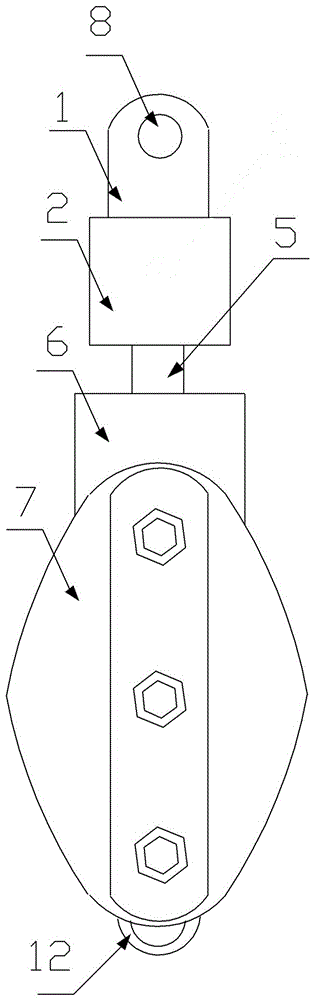

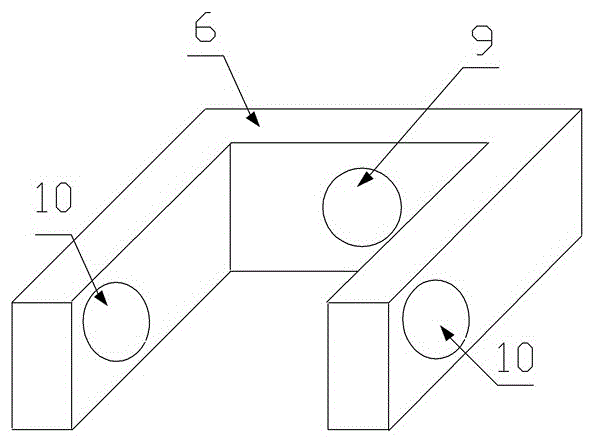

[0025] Embodiment: An insulating digital real-time monitoring load-bearing device for live work, including a hanging lug 1, a hanging beam 6, a pulley and bolt assembly 7, and a display 14. The hanging lug 1 is provided with a first bolt hole 8, and the lower end of the hanging lug 1 is Connected with the installation body 2 of the tension conversion sensor, the tension conversion sensor installation body 2 is provided with a tension conversion sensor (not shown in the figure), the tension conversion sensor installation body 2 is provided with a protective door 3 and a wireless sensor 4, the tension conversion sensor The lower end of the installation body 2 is connected with the first bolt 5, the hanging lug 1, the tension conversion sensor installation body 2 and the first bolt 5 are an integrated structure, the hanging beam 6 is provided with the second bolt hole 9 and the third bolt hole 10, the second A bolt 5 is connected with the suspension beam 6 through the second bolt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com