Laser marking and positioning device and construction spring line marking and positioning method thereof

A positioning device, laser marking technology, applied in the direction of measuring point marking, etc., can solve the problems of unfavorable identification, insufficient marking position accuracy, etc., and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

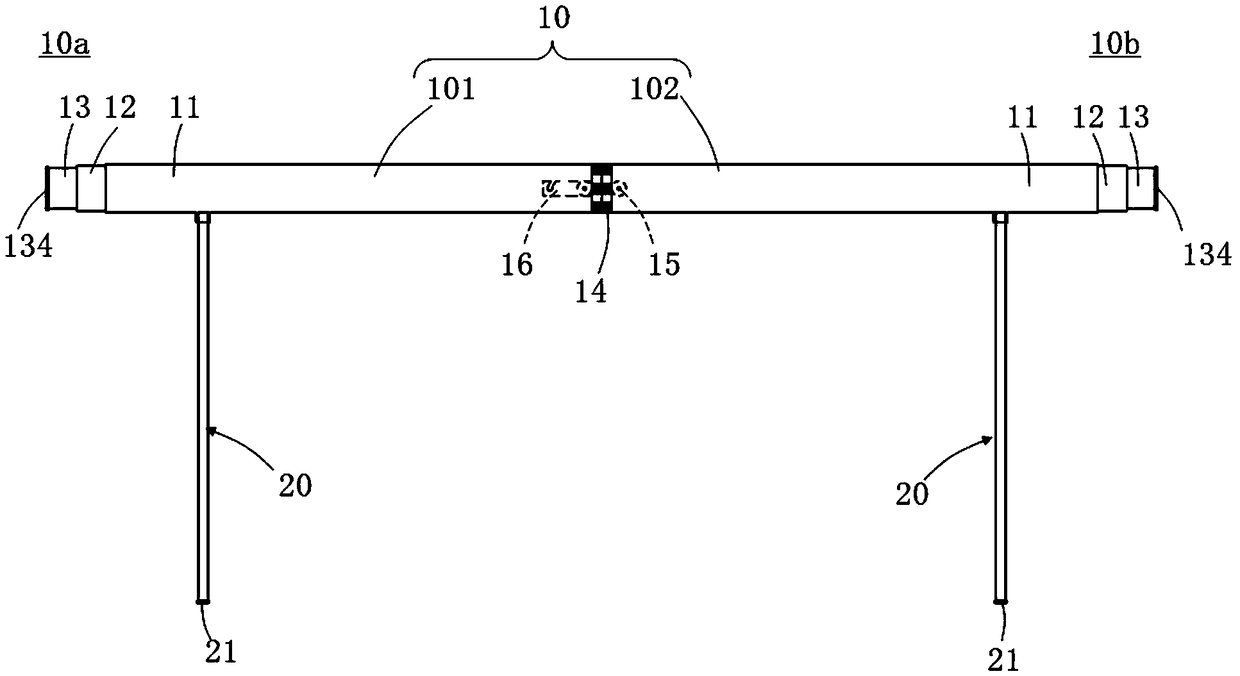

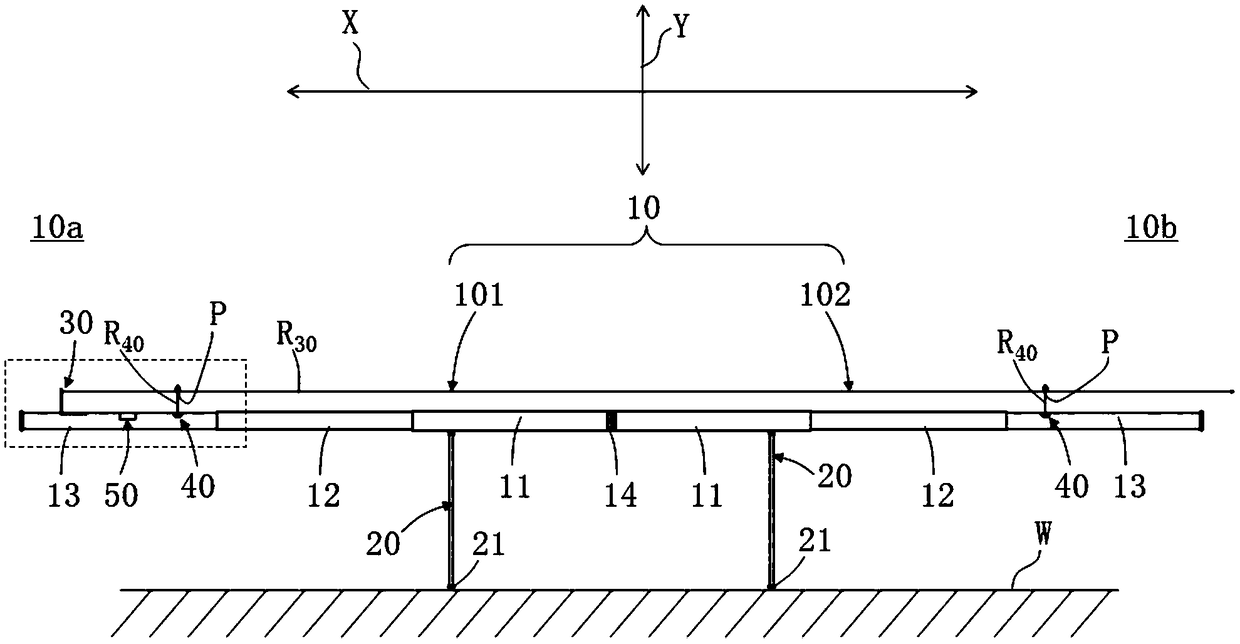

[0036] see Figure 1 to Figure 6 , the present invention provides a laser marking positioning device, which includes a main support 10 , at least two legs 20 , a first wavelength laser 30 , at least two second wavelength lasers 40 and a power supply module 50 . in:

[0037] Such as figure 1 , figure 2 , the main bracket 10 has an opposite first end 10a and a second end 10b, the first end 10a is formed by a first telescopic rod 101, and the second end 10b is formed by a second telescopic rod 102; The first telescopic rod 101 includes an intermediate rod 11, a connecting rod 12 and an end rod 13 which are nested in each other, and the second telescopic rod 102 also includes an intermediate rod 11 and a connecting rod which are nested in each other. 12 and a terminal rod 13.

[0038] Such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com