Intelligent projection welding subassembly gauge and detection method thereof

A technology of sub-assemblies and inspection tools, used in measuring devices, instruments, etc., can solve the problems of difficult to guarantee the accuracy of inventory, multi-time projection welding products, safety impact of the company and users, etc., to ensure quality and reduce work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

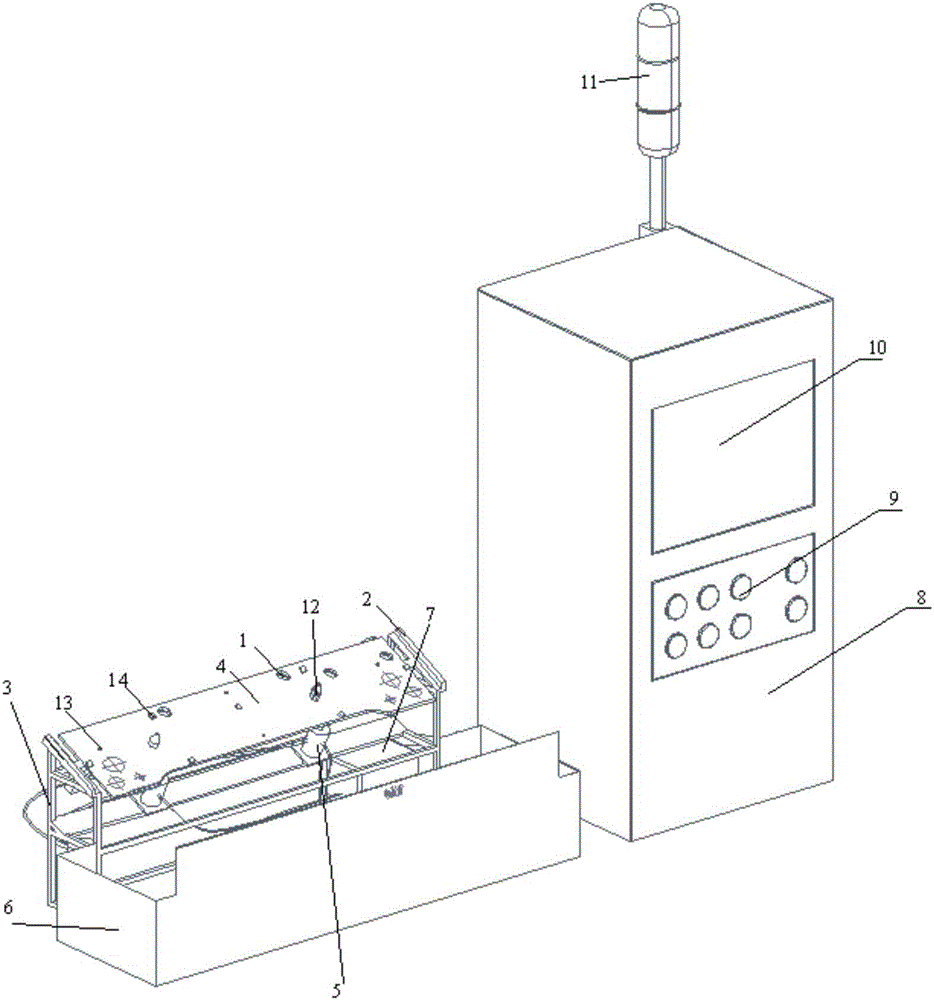

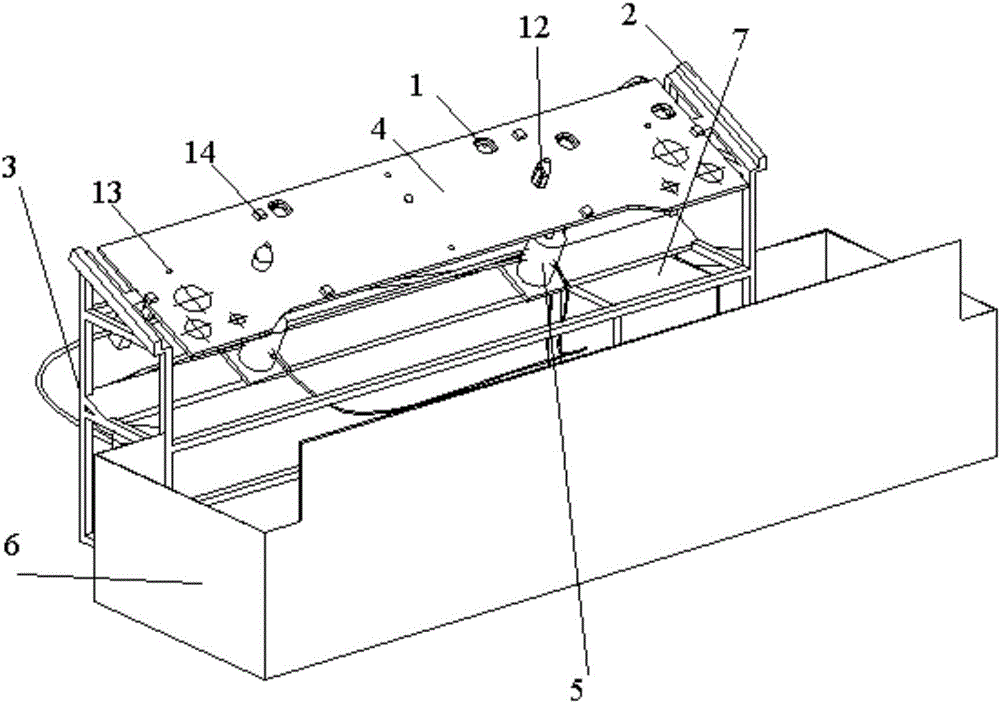

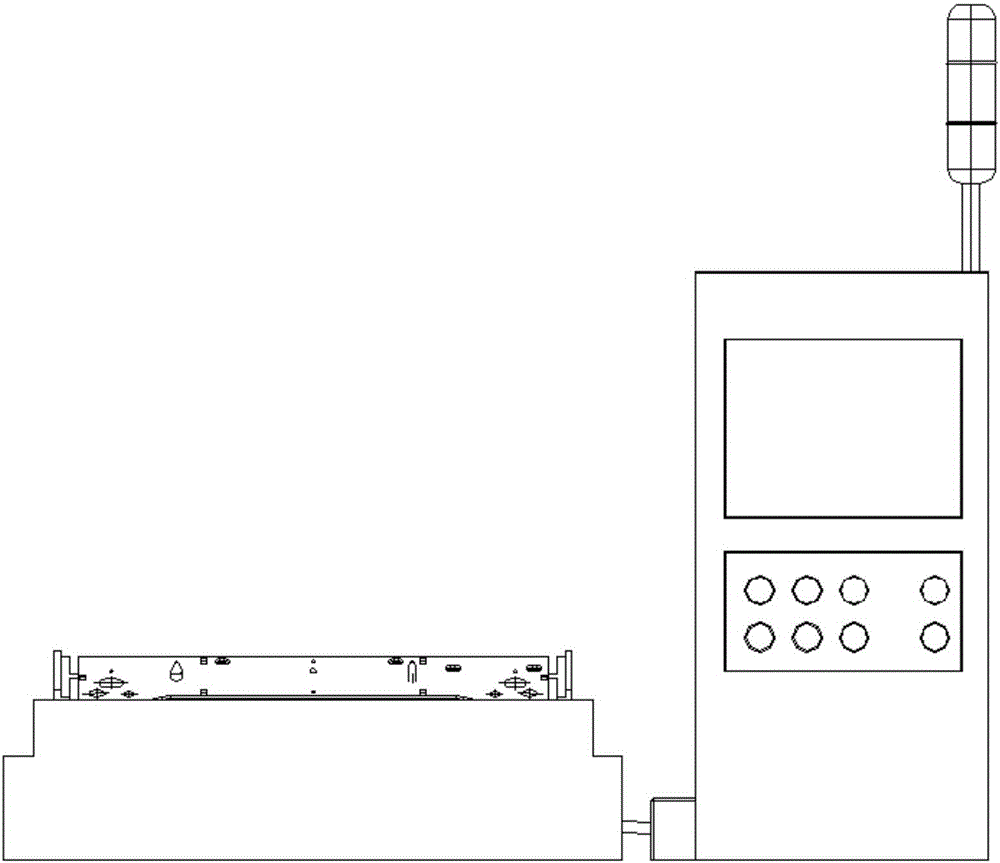

[0021] like Figure 1-5 As shown, the inspection tool for the intelligent projection welding subassembly includes a detection mechanism, a control mechanism and a loading box 6; Between the roads 2 is the detection surface 4, on which there are component sensors 1, distance sensors 13, reference blocks 14, and positioning pins 12, the bottom of the detection surface 4 is connected with pneumatic components 5, and the control box 7 is set on the inspection fixture bracket 3 The bottom of the bottom of the control box 7 is connected to the control mechanism, and the other side of the control box 7 is connected to the component sensor 1 and the distance sensor 13. The product slideway 2 and the detection surface 4 are all inclined towards the loading box 6; the control mechanism includes Control box 8 and buzzer 11, control box 8 is provided with manual button 9 and display screen 10. The manual button 9 is used for setting functions or adjusting display information. The height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com