Indirect type geometrical parameter measuring and performance optimizing method for fan rotor

A technology of fan rotor and optimization method, applied in the direction of measuring device, measuring ultrasonic/sonic wave/infrasonic wave, using wave/particle radiation, etc., can solve the problem of unbalanced load of wind power generating set, so as to prevent unit fatigue and failure, and solve load The effect of unbalanced problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] The following figures are used for illustration and simplification of description, and only important details relevant to understanding the present invention are kept, other details have been omitted. In the drawings, the same reference numerals and symbols are used for the same parts.

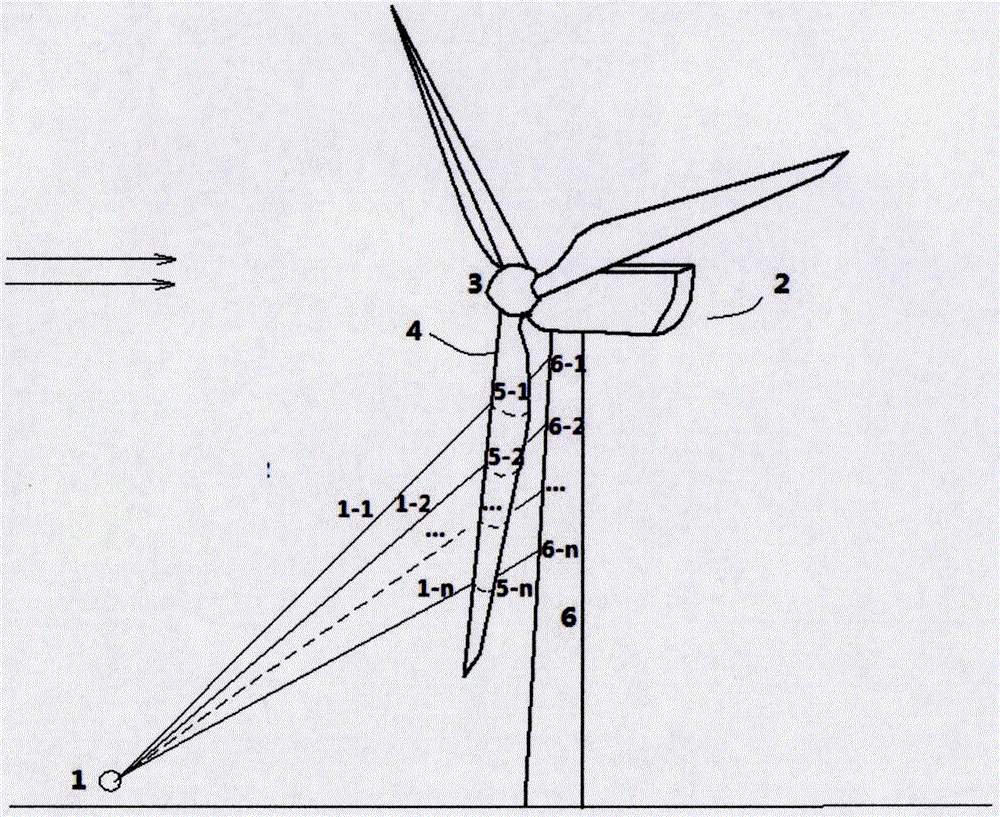

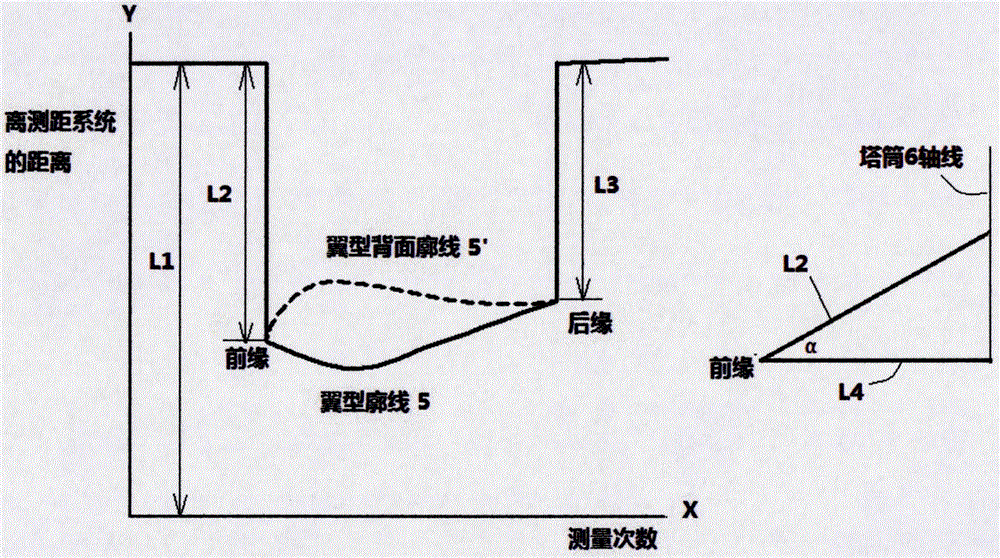

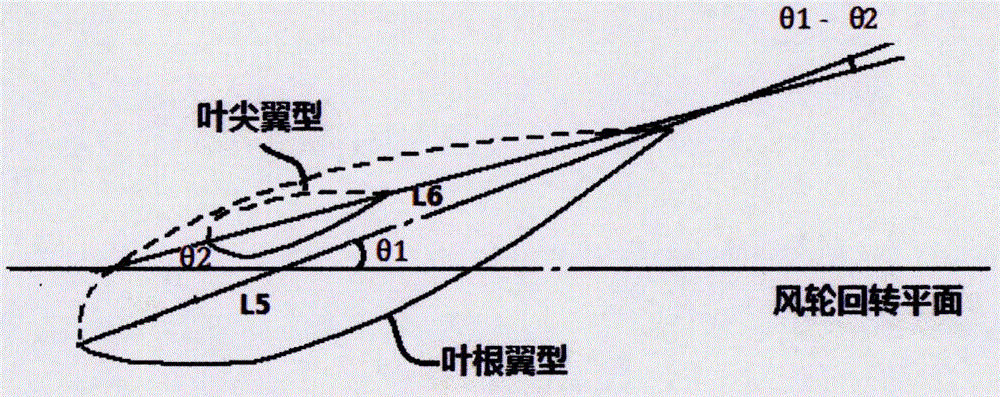

[0040] figure 1 A schematic diagram of dynamic scanning of the blades 4 on the rotor 3 of the wind power generating set 2 and the wind tower 6 by using the long-distance laser ranging system 1 is described. Among them, the laser ranging system 1 is located at 60 to 200 meters on the windward side of the wind turbine. A series of beams 1-1, 1-2, ..., 1-n emitted by the laser ranging system intersect with the surface of the moving fan blades. The motion trajectory is exactly the profile 5-1, 5-2, ..., 5-n of the airfoil at different positions of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com