Pulsating direct current traction electric power supply system

A traction power supply system, pulsating DC technology, applied in power lines, irreversible AC power input conversion to DC power output, transportation and packaging, etc. It can improve the reliability of power supply, solve the load imbalance, and improve the terminal voltage level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

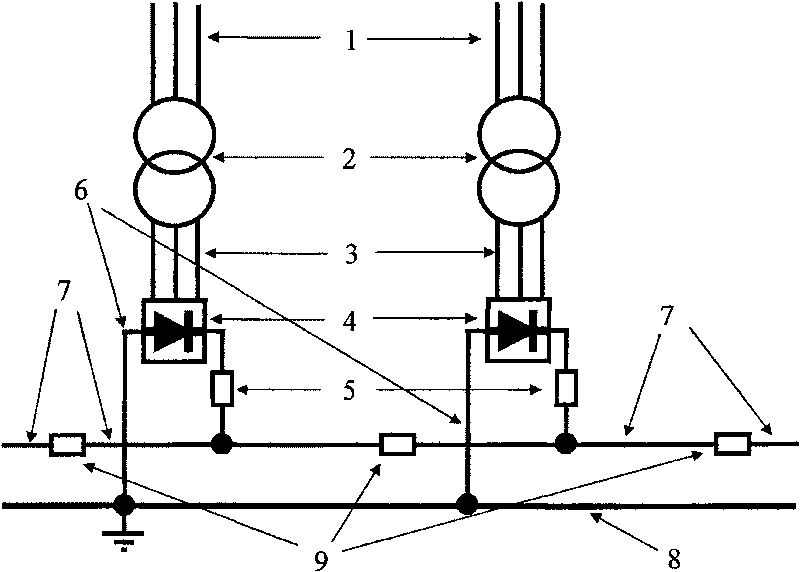

[0016] Such as figure 1 As shown, the pulsating DC traction power supply system consists of three-phase 220KV or 110KV power supply input terminal (1), three-phase 220KV / 25KV or 110KV / 25KV traction transformer (2), traction power supply three-phase output 25KV busbar (3) , three-phase rectification device (4), 25KV pulsating DC output circuit breaker (5), return line (6), electrified railway power supply section catenary (7), rail (8) and catenary contact circuit breaker (9) composition.

[0017] The input terminal of the three-phase 220KV or 110KV power supply of the power device is (1) connected to the three-phase 220KV / 25KV or 110KV / 25KV traction transformer (2), the three-phase output 25KV busbar for traction power supply (3), and the three-phase rectifier (4 ), a 25KV pulsating DC output circuit breaker (5), and a return line (6) form a traction power supply transformation system. A plurality of electrified railway power supply section catenaries (7) are connected into ...

Embodiment 2

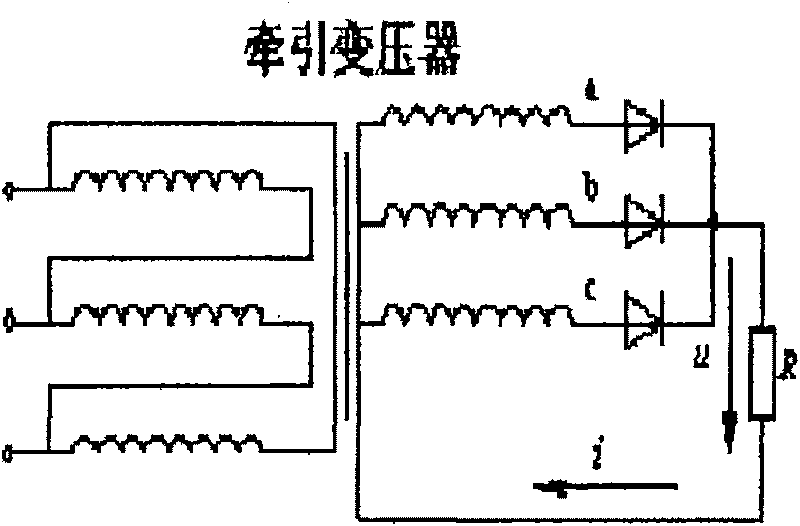

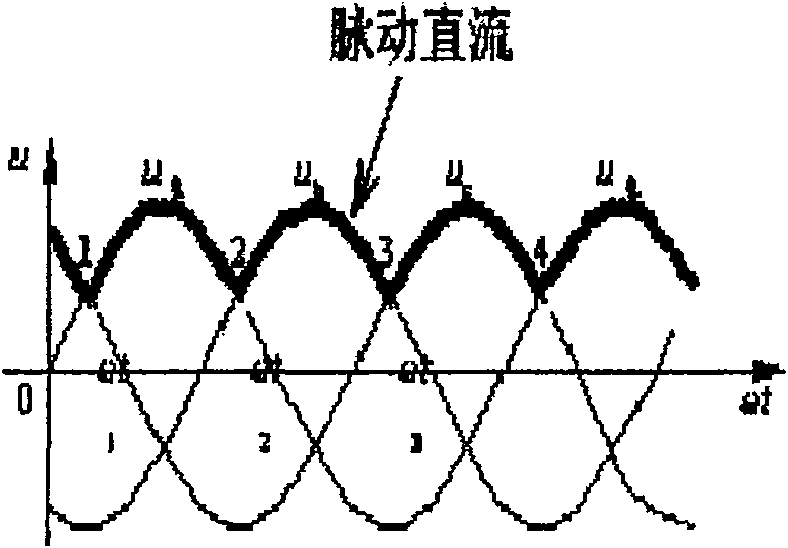

[0020] The schematic wiring diagram and output voltage waveform diagram of the three-phase rectifier (4) are shown in Figure 2-Figure 5 .

[0021] figure 2 , image 3 It is the schematic wiring diagram and the output voltage waveform diagram of the three-phase half-wave rectifier (4). It can be seen from the figure that the voltage on the load R of the electric locomotive is a pulsating DC voltage.

[0022] Figure 4 , Figure 5 It is the schematic wiring diagram and the output voltage waveform diagram of the three-phase full-wave rectifier (4). It can be seen from the figure that the voltage on the load R of the electric locomotive is a pulsating DC voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com