A single-tube combustor of a ground gas turbine with axial intake

A gas turbine, axial intake technology, applied in the combustion chamber, continuous combustion chamber, combustion method and other directions, can solve the problems of additional pressure loss in turning, asymmetric flow, large cooling area of the flame tube, etc., to reduce high temperature hot spots, improve Turbine life, achieving the effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

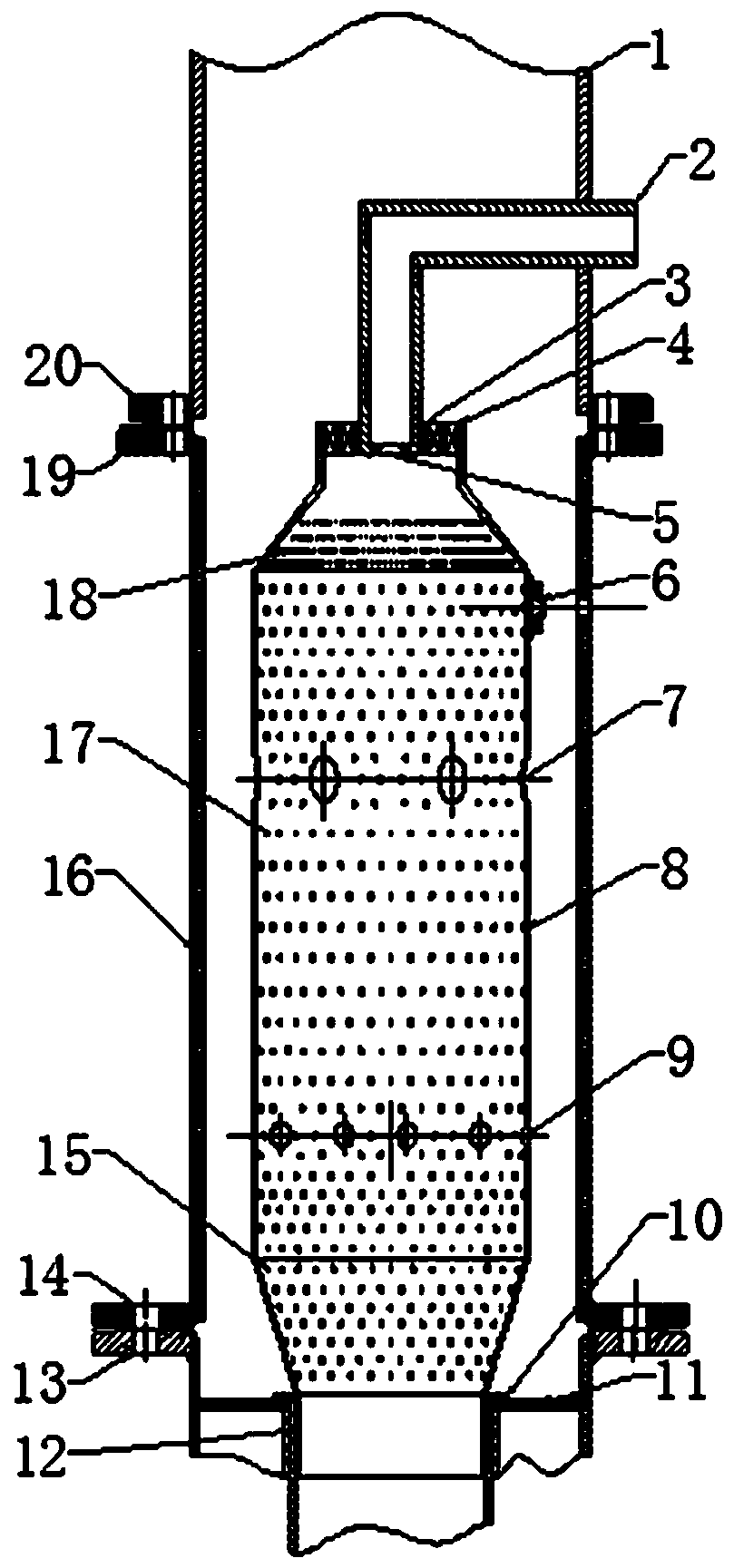

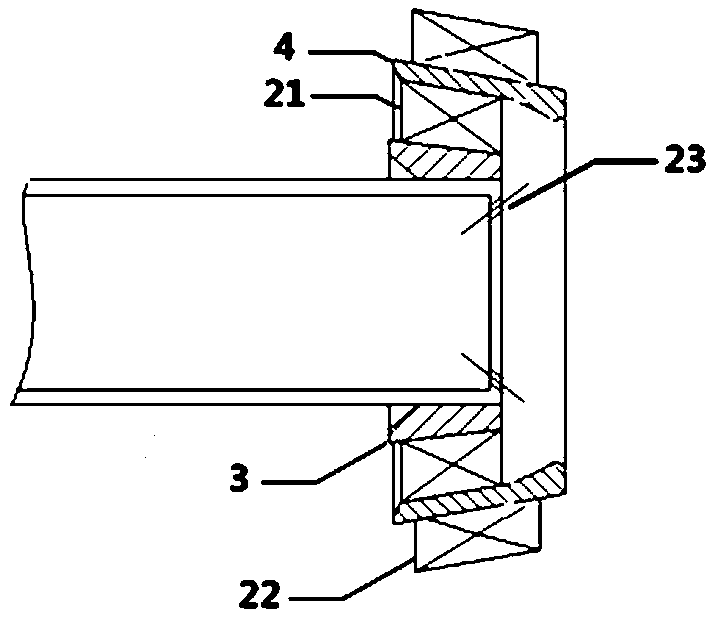

[0026] Such as figure 1As shown, a single-pipe combustion chamber of a ground gas turbine with axial air intake in the present invention includes a combustion chamber intake pipe 1, a casing 16, and the upper end of the casing 16 described in the combustion chamber outlet section 12 is connected with a combustion chamber intake pipe 1 , the lower end of the casing 16 is connected with the outlet section 12 of the combustion chamber, and the hollow end surrounded by the three is equipped with a flame cylinder 8, and the flame cylinder 8 is installed on the upper end of the outlet section 12 of the combustion chamber; the flame cylinder 8 is fixed through the natural gas inlet pipe 2 and the combustion chamber intake pipe 1; the top of the flame cylinder 8 is equipped with a natural gas burner 5; one end of the natural gas inlet pipe 2 is connected with the natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com