Powder blower fixing frame

A powder sprayer and fixed frame technology, which is applied in the direction of supporting machines, machine tables/supports, mechanical equipment, etc., can solve the problems of reduced operating efficiency, inconvenient picking and placing of the powder sprayer, and low efficiency of two-handed operation, and achieve stable positioning Reliable, easy to pick and place, convenient transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

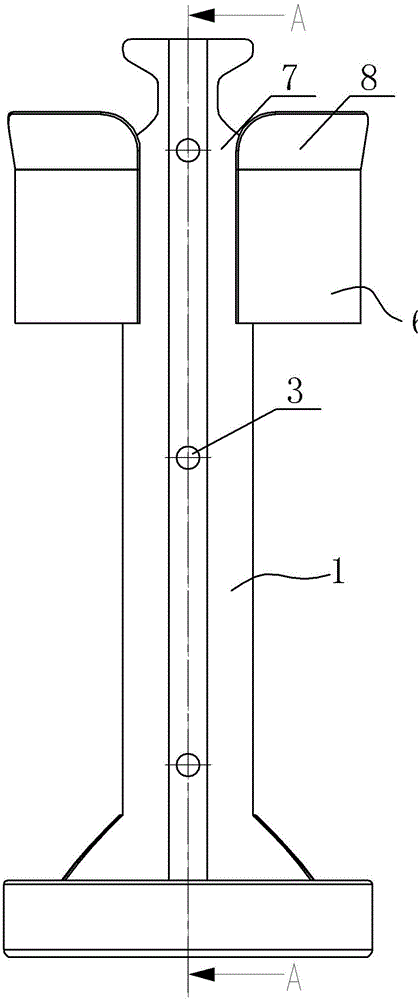

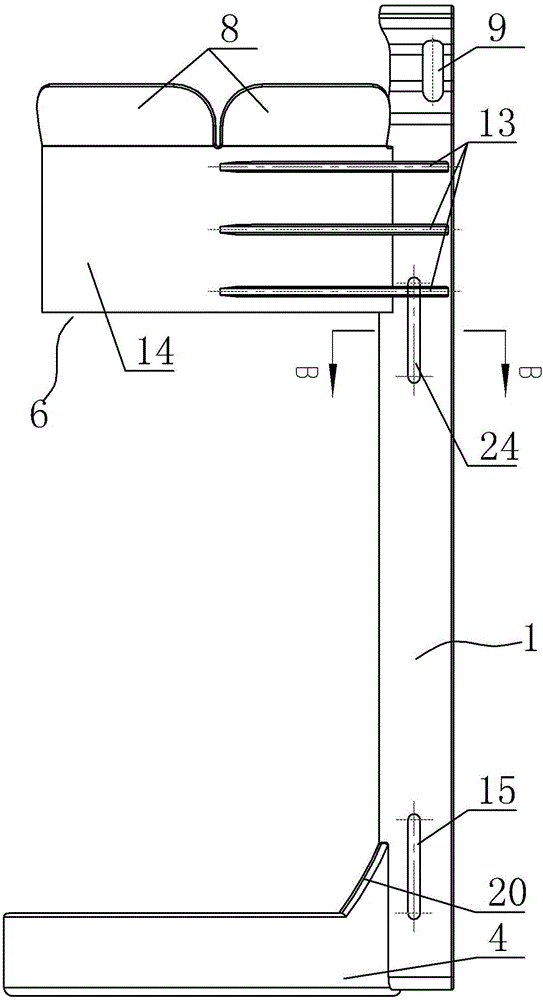

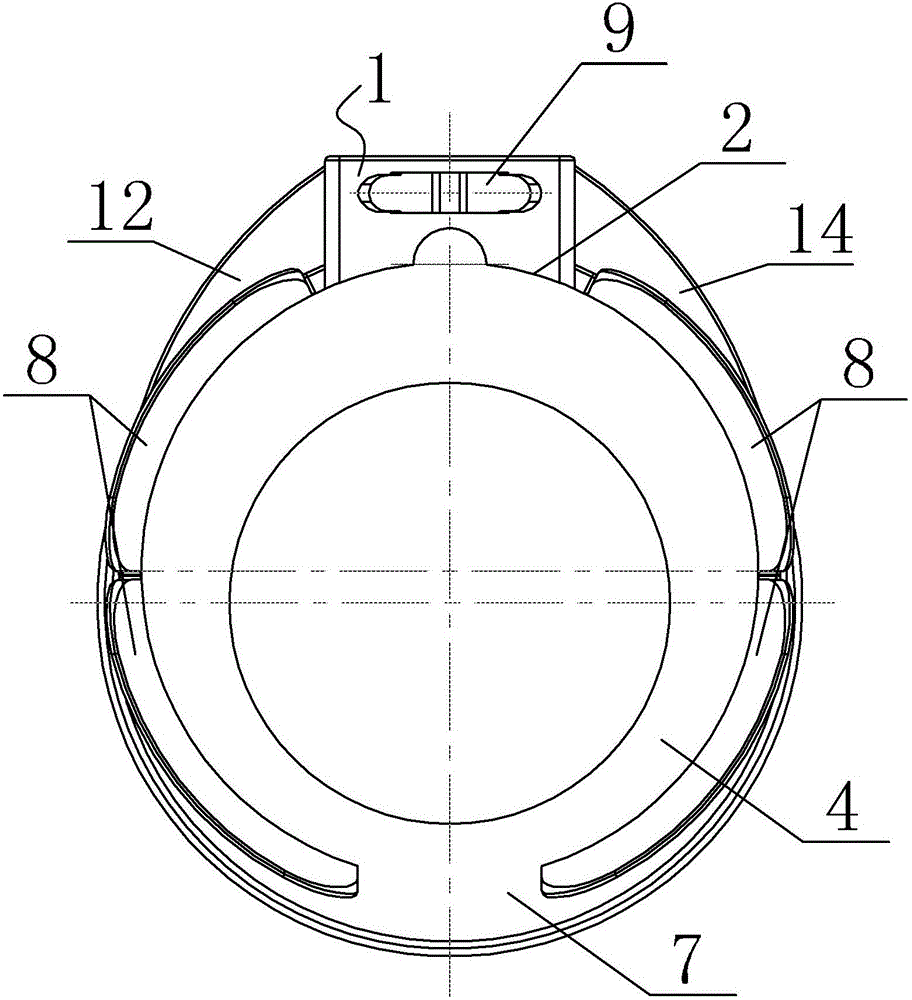

[0034] Specific examples: see figure 2 , Figure 5 , Figure 9 The two side walls 23 of the column 1 are respectively provided with an upper cable tie positioning hole 24 and a lower cable tie positioning hole 15 corresponding to the position between the bottom positioning ring 4 and the upper positioning snap ring 6, and the upper cable tie 16 runs through the two positions respectively. The upper cable tie positioning hole 24 on the side wall and the lower cable tie 17 respectively pass through the lower cable tie positioning holes 15 located on the two side walls. The shapes of the upper cable tie 16 and the lower cable tie 17 can be adjusted arbitrarily according to the powder sprayer to be fixed , when the powder sprayer is fixed, the upper cable tie 16 and the lower cable tie 17 are arranged close to the human body or the structure to be fixed; the upper cable tie positioning hole 24 and the lower cable tie positioning hole 15 are specifically long slot structures para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com