A solenoid valve with automatic regulation function

A solenoid valve and functional technology, applied in the mechanical field, can solve the problems of inaccurate adjustment of exhaust gas flow, real-time monitoring of exhaust gas flow, and inability to judge the location of solenoid valve failure in time, so as to change the flow rate and repair it in time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

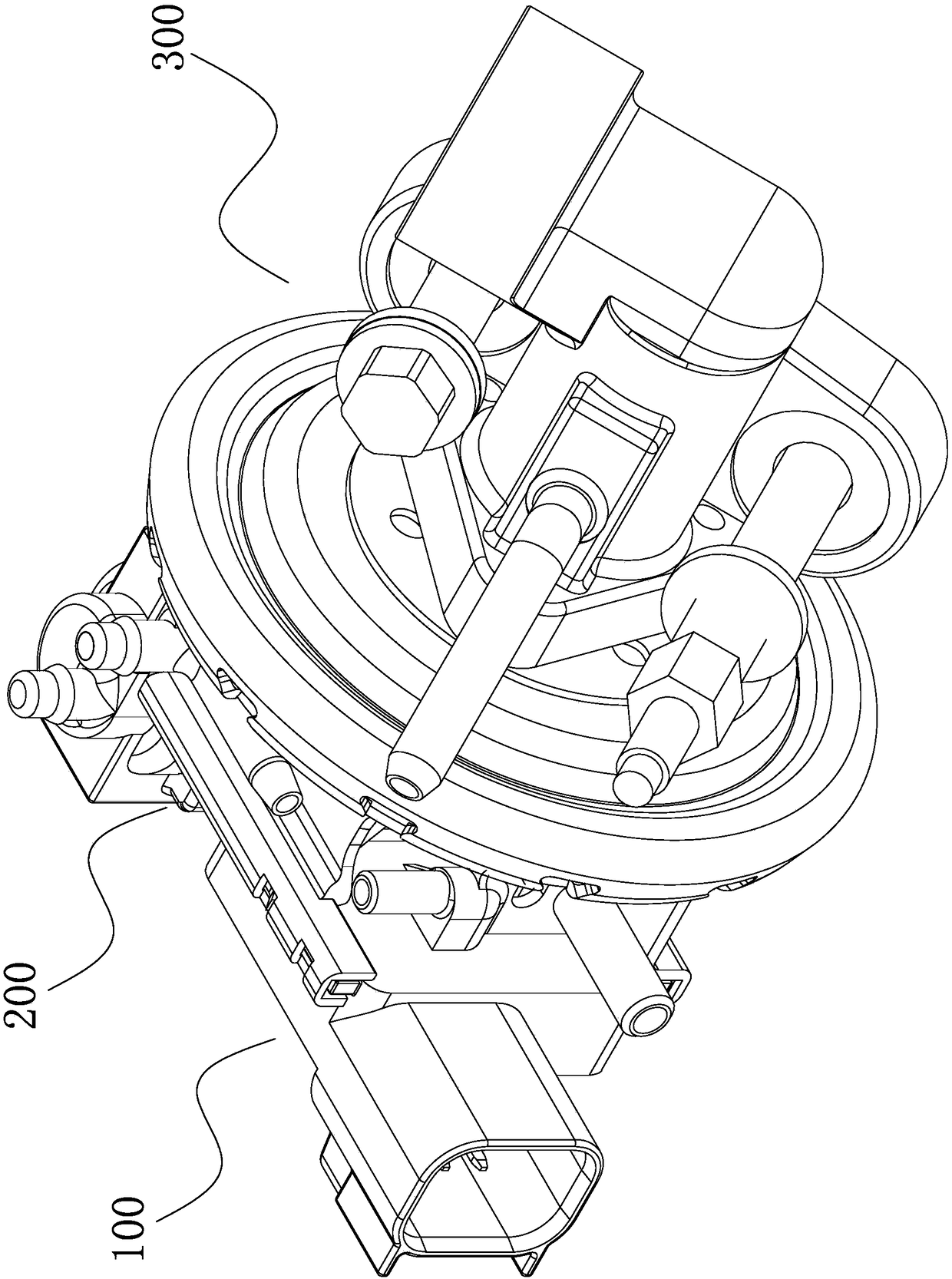

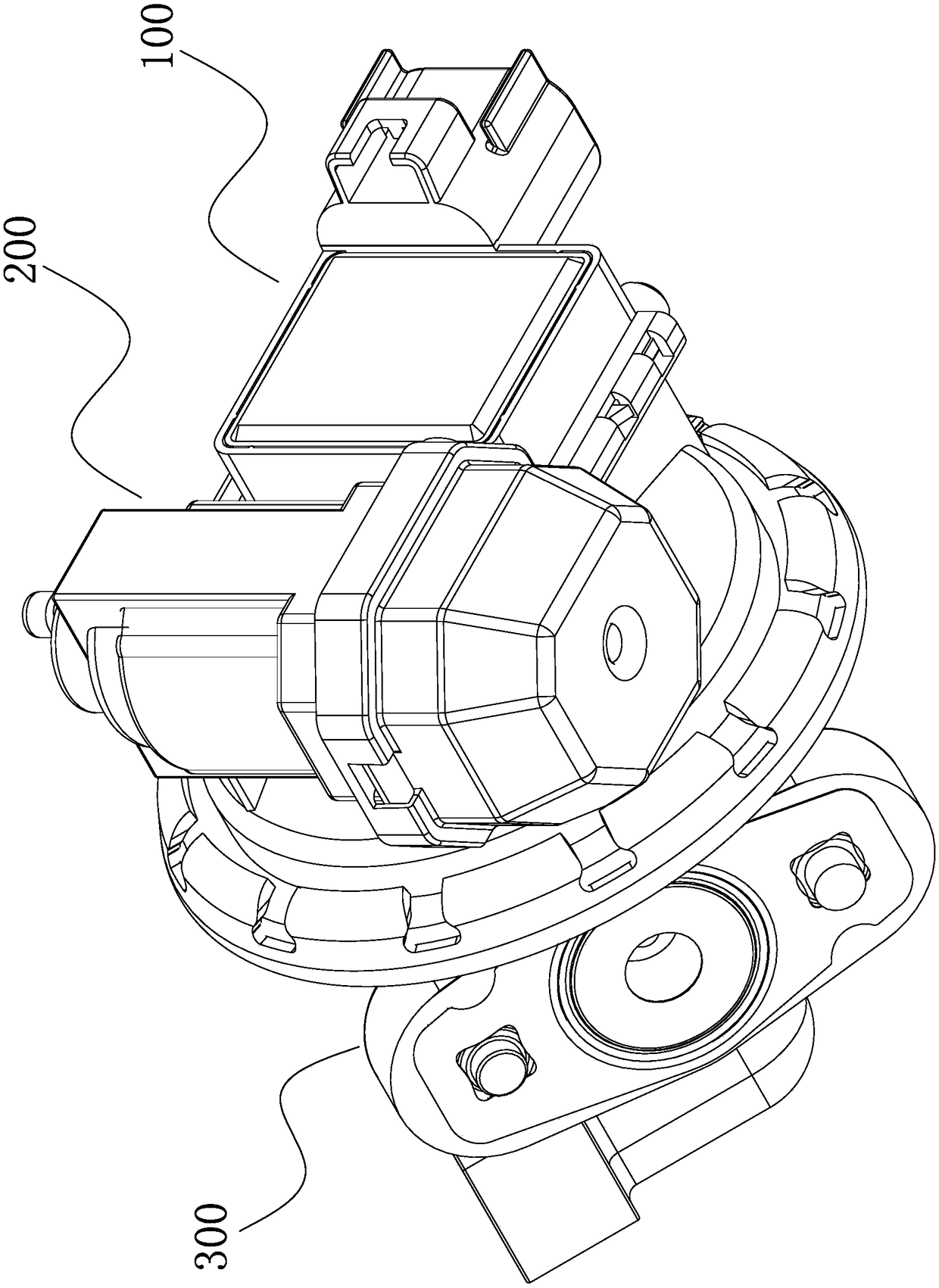

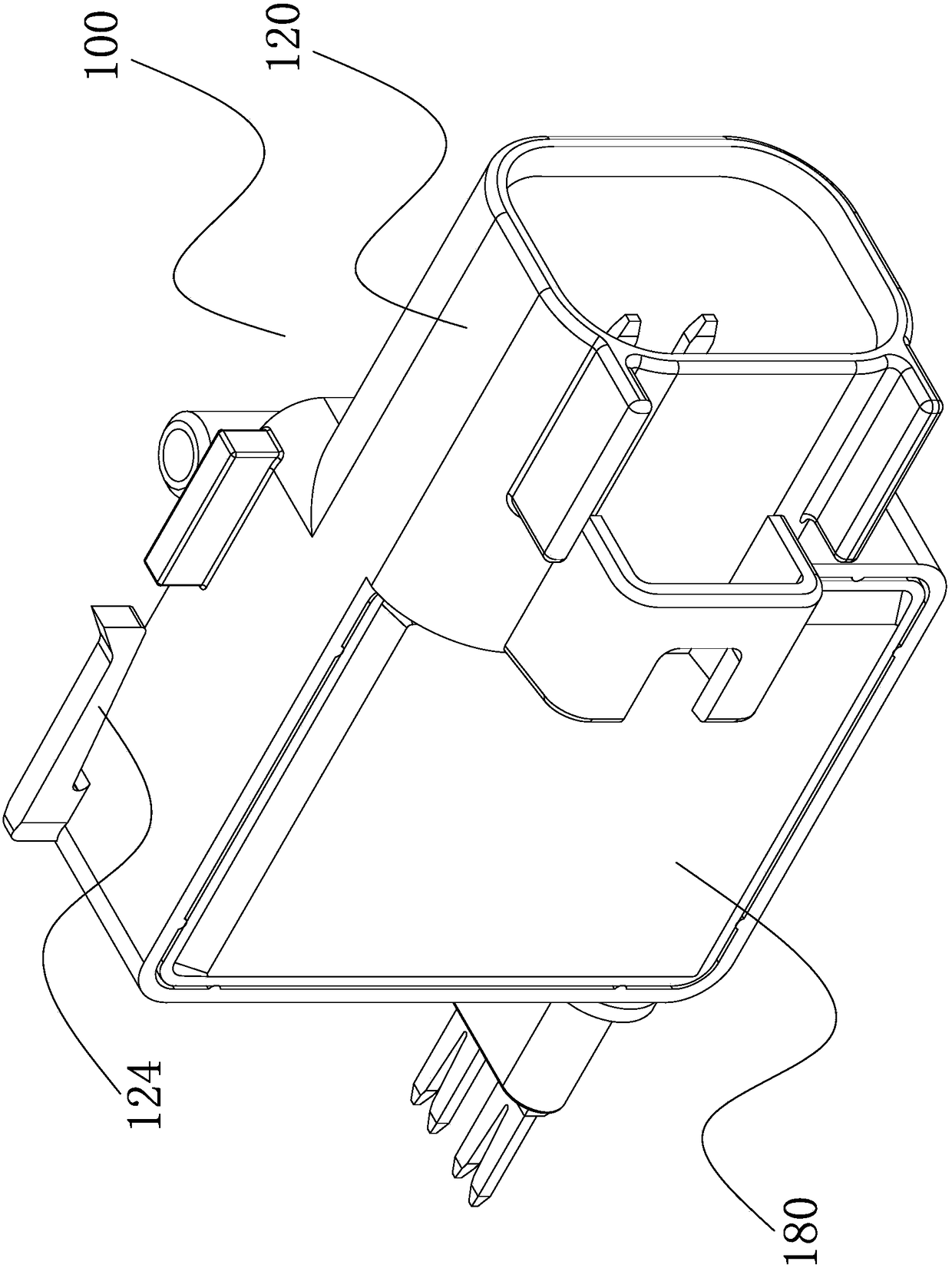

[0047] Such as figure 1 , figure 2 as well as Figure 5 As shown, the present invention provides a solenoid valve with automatic regulation function, including: a control mechanism 100, including a bottom case 120 containing a main circuit board 110, and one side of the bottom case 120 is provided with two mutually perpendicular first A connecting nozzle 130, wherein, two first connecting nozzles 130 are respectively connected with the chips on the main circuit board 110; the trigger mechanism 200 is connected with the control mechanism 100, and one side of the trigger mechanism 200 is provided with a built-in electromagnet The magnet box 210, wherein, the magnet box 210 is provided with a nozzle assembly 220, and one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com