Wall sticker

A wall and film sticking technology, applied in covering/lining, building, building structure, etc., can solve problems such as fuzziness, inability to purify indoor air, wallpaper is not suitable for application, etc., and achieve strong sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0015] The wall film of this embodiment includes a base material layer, a pattern layer arranged on one surface of the base material layer and an adhesive layer arranged on the other side of the base material layer, and also includes a In the protective glue film, glue drops are arranged on the surface of the pattern on the pattern layer, and the outline of the pattern on the pattern layer is coated with a glue drop stopper.

[0016] The substrate layer described in this embodiment is made of a bendable PVc film material, which plays a role in supporting the entire film, and the pattern layer is provided with a plurality of rectangular planar printing patterns arranged in an array.

[0017] The color of the pattern can be set according to needs, there is a certain distance between the square patterns, and glue drops are arranged on the surface of each square pattern, and the glue drop stopper is applied to the gaps formed by the square patterns, so as to Make sure that the sha...

Embodiment 2

[0019] The wall film of this embodiment includes a base material layer, a pattern layer arranged on one surface of the base material layer and an adhesive layer arranged on the other side of the base material layer, and also includes a In the protective glue film, glue drops are arranged on the surface of the pattern on the pattern layer, and the outline of the pattern on the pattern layer is coated with a glue drop stopper.

[0020] In this embodiment, the substrate layer described in this embodiment is a bendable PET film, which plays a role in supporting the entire film, and the pattern layer is provided with a plurality of square patterns arranged in an array, and the pattern is concave-convex three-dimensional The pattern makes the film have individual characteristics different from that of the general film. The color of the pattern can be set according to the needs. There is a certain distance between the square patterns. There are glue drops on the surface of each square...

Embodiment 3

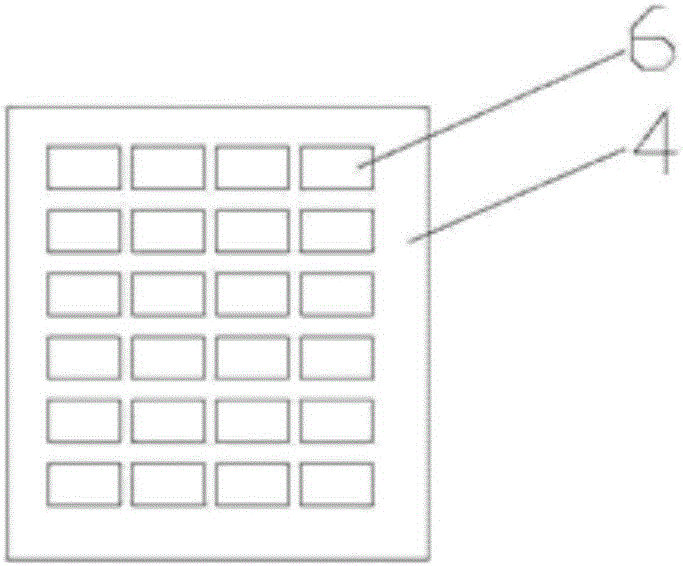

[0022] As shown in Figure 1-12, the wall film of this embodiment includes a base material layer 4, a pattern layer arranged on one surface of the base material layer and an adhesive layer 2 arranged on the other side of the base material layer, and also includes The protective adhesive film 1 attached to the adhesive layer, wherein the surface of the pattern on the pattern layer is provided with glue drops 5, and the outline of the pattern on the pattern layer is coated with a glue drop stopper.

[0023] In this embodiment, the substrate layer described in this embodiment is a bendable PP film, which plays a role in supporting the entire film. The pattern layer is provided with a plurality of rectangular patterns 6 arranged in an array. The color of the patterns is It can be set according to needs, there is a certain distance between the rectangular patterns, and there are glue drops on the surface of each rectangular pattern, and the glue drop stopper is in the gap formed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com