Reusable drainage well

A technology for drainage wells and drainage pipes, applied in drainage structures, waterway systems, water supply devices, etc., can solve the problems of long construction period, easy loss of manhole covers, and short service life, so as to improve construction efficiency, facilitate product transportation, and reduce transportation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

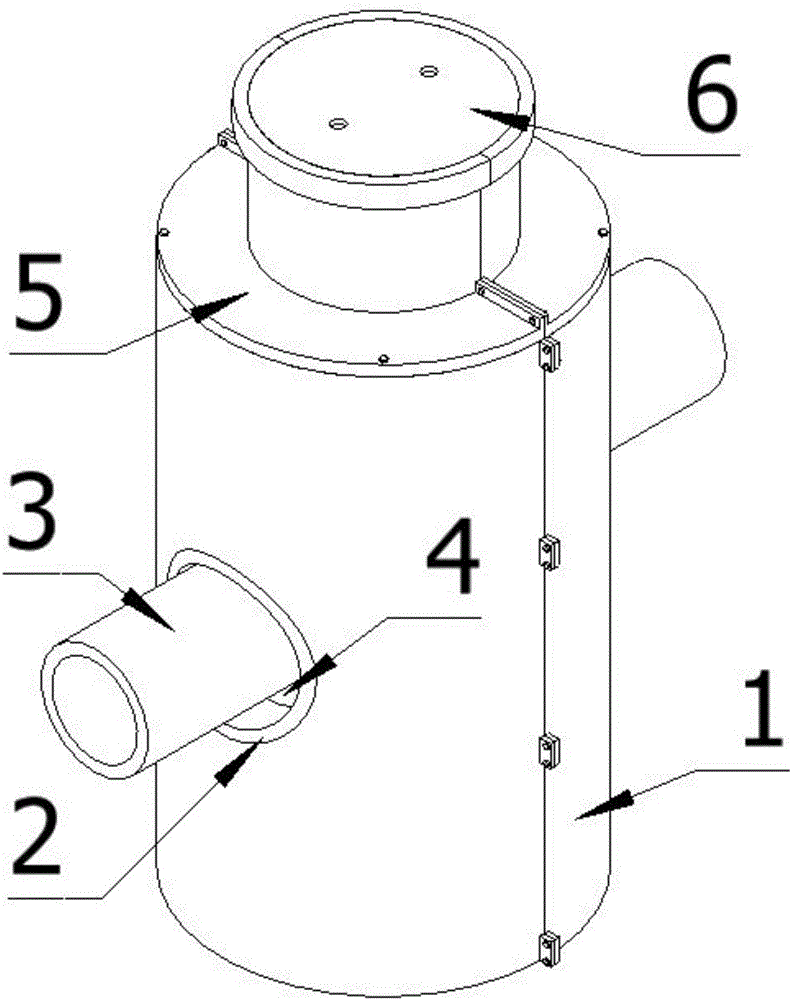

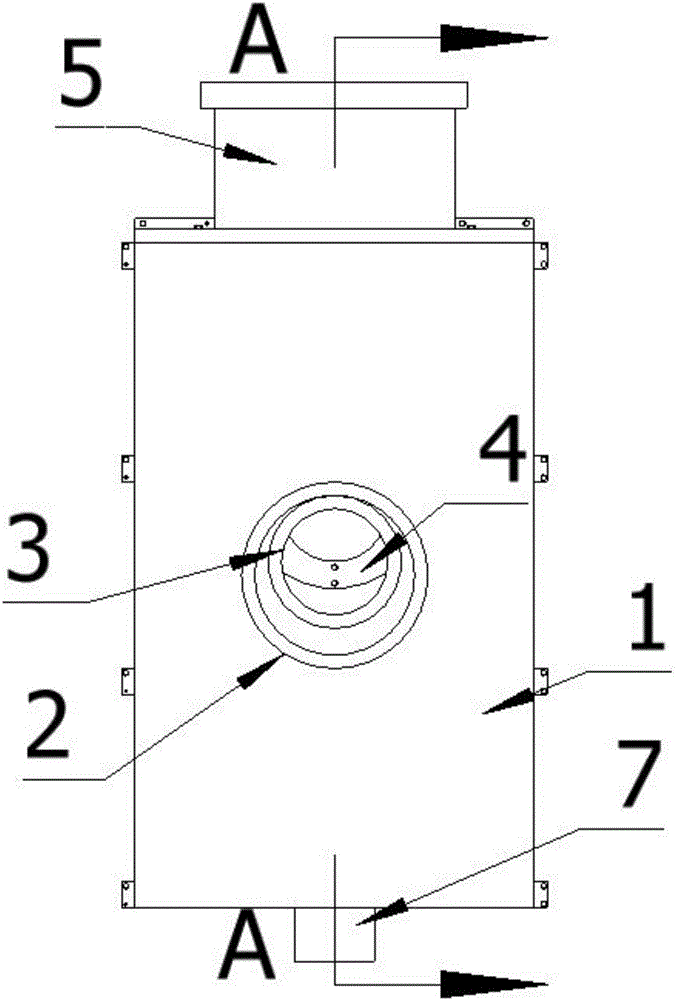

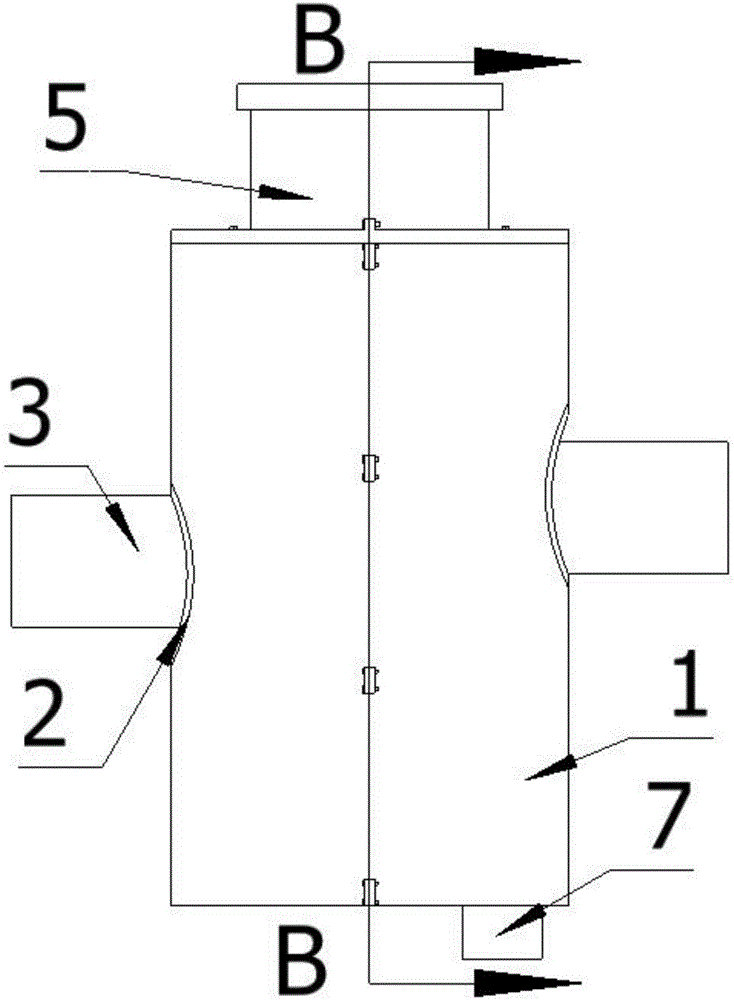

[0041] Figure 1 to Figure 8 , Figure 11 to Figure 13 It is the first embodiment of the present invention. As shown in the figure, a reusable drainage well includes a well body 1, a butt joint pipe 2, a flange plate 4, a well neck 5, a well cover 6, a drainage groove 7, and a well The body 1 is a cylindrical hollow shell with an opening at the top. The butt joint 2 is arranged inside the well body 1. The butt joint 2 is perpendicular to the side of the well body 1. There are at least two butt joints 2. The drain pipe 3 is inserted into the butt joint 2 to drain water. The end face of the pipe 3 near the axis of the well body 1 coincides with the end face of the butt pipe 2 near the axis of the well body 1, the inner diameter of the butt pipe 2 is much larger than the outer diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com