Pile sinking construction method based on assembly movable platform

A construction method and a mobile technology, which can be applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of time-consuming and labor-intensive concrete pile foundations, difficult construction, and poor environmental protection effects, so as to improve pile sinking efficiency and facilitate construction Fast, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

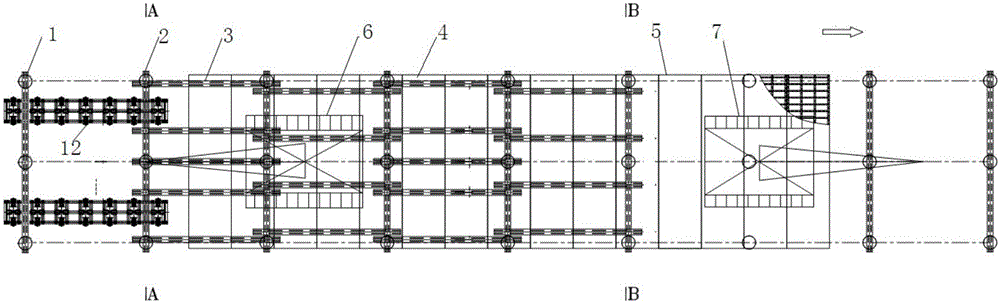

[0036] Such as figure 1 As shown, the present invention provides a kind of construction method based on assembling mobile platform to carry out pile sinking, it is characterized in that: it comprises the following steps:

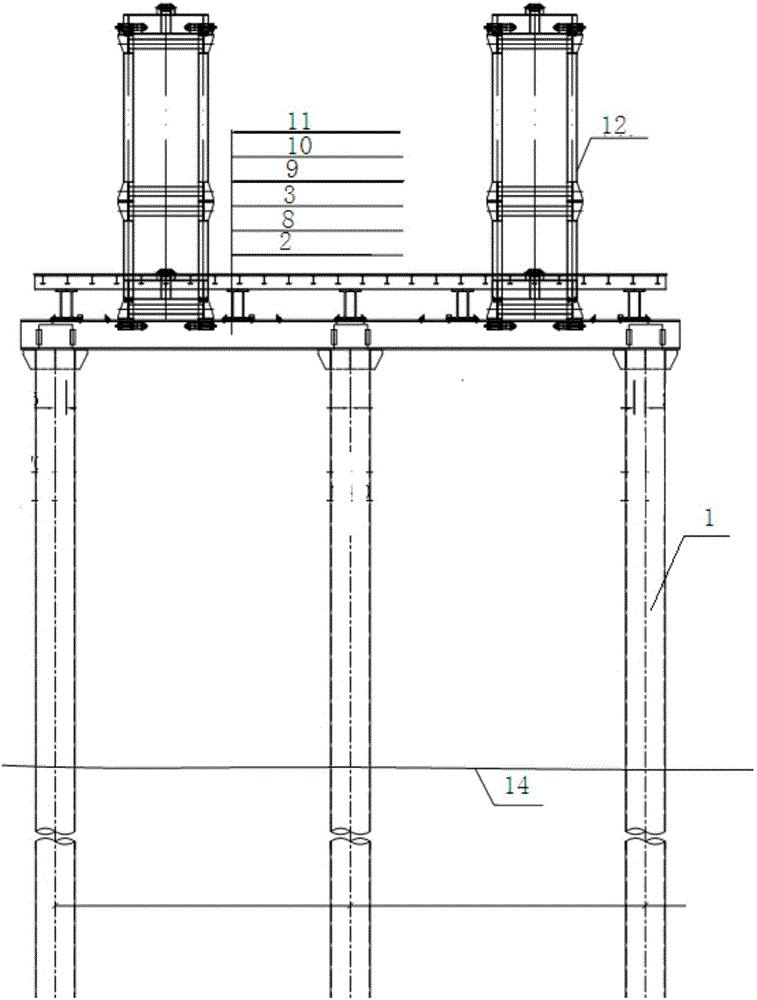

[0037] a. Construct steel pipe piles 1 side by side along the laying direction of sheet piles in the sheet pile construction area, the bottom surface of steel pipe piles 1 is located below the mud surface line 14, and there are 3 steel pipe piles 1 in each row;

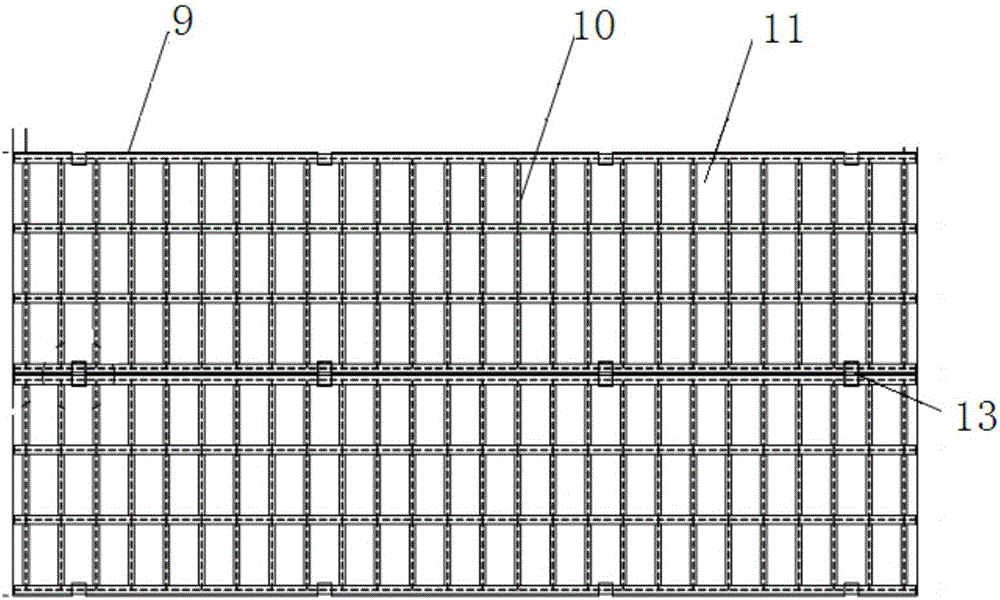

[0038] b. A crossbeam 2 is set on the top of each row of steel pipe piles 1, and three steel pipe piles 1 jointly support the crossbeam 2 to ensure the stability of the crossbeam 2; the top of the steel pipe pile 1 is provided with a cross-shaped pile m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com