A method for preparing hot-dip galvanized warm-formed high-strength medium-manganese steel parts

A warm forming, high-strength technology, applied in hot-dip plating process, coating, metal material coating process, etc., to achieve the effect of improving adhesion, improving efficiency, and good surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

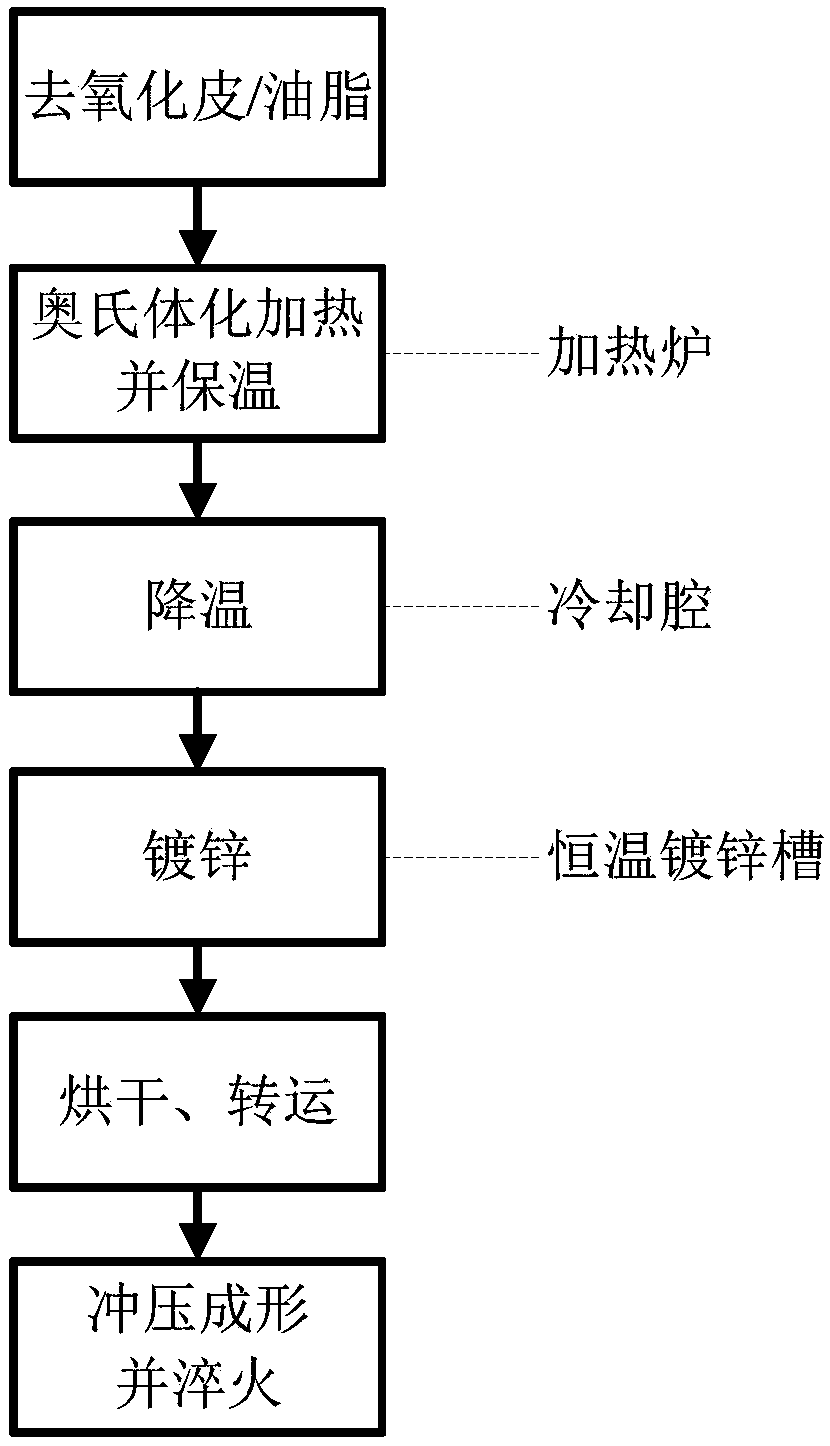

[0025] A preparation method for hot-dip galvanized warm-formed high-strength medium-manganese steel parts, comprising the following steps (such as figure 1 shown):

[0026] S1. Select the smelted, hot-rolled, and cold-rolled medium manganese steel plate for derusting and degreasing treatment in advance as the steel piece to be used. The chemical composition weight percentage of the medium manganese steel plate is: C: 0.05-0.50%; Mn: 4.0-6.0%; Al: 0.015-0.060%; P≤0.015%; S≤0.02%, the rest is Fe and unavoidable impurities; on the basis of the chemical composition of the medium manganese steel plate, one of the following weight percentages is added Or multiple elements: Ni: 0.1-3.0%; Cr: 0.2-3.0%; Mo: 0.1-0.8%; Cu: 0.5-2.0%; B: 0.0005-0.005%; Nb: 0.02-0.10%; [N] : 0.002-0.25%; Ti: 0.05-0.25%; V: 0.02-0.25%; Re: 0.002-0.005%; Ca: 0.005-0.03%;

[0027] S2. Heat the steel parts to be used in a vacuum heating furnace to the austenitization temperature to avoid oxidation of the stee...

Embodiment 1

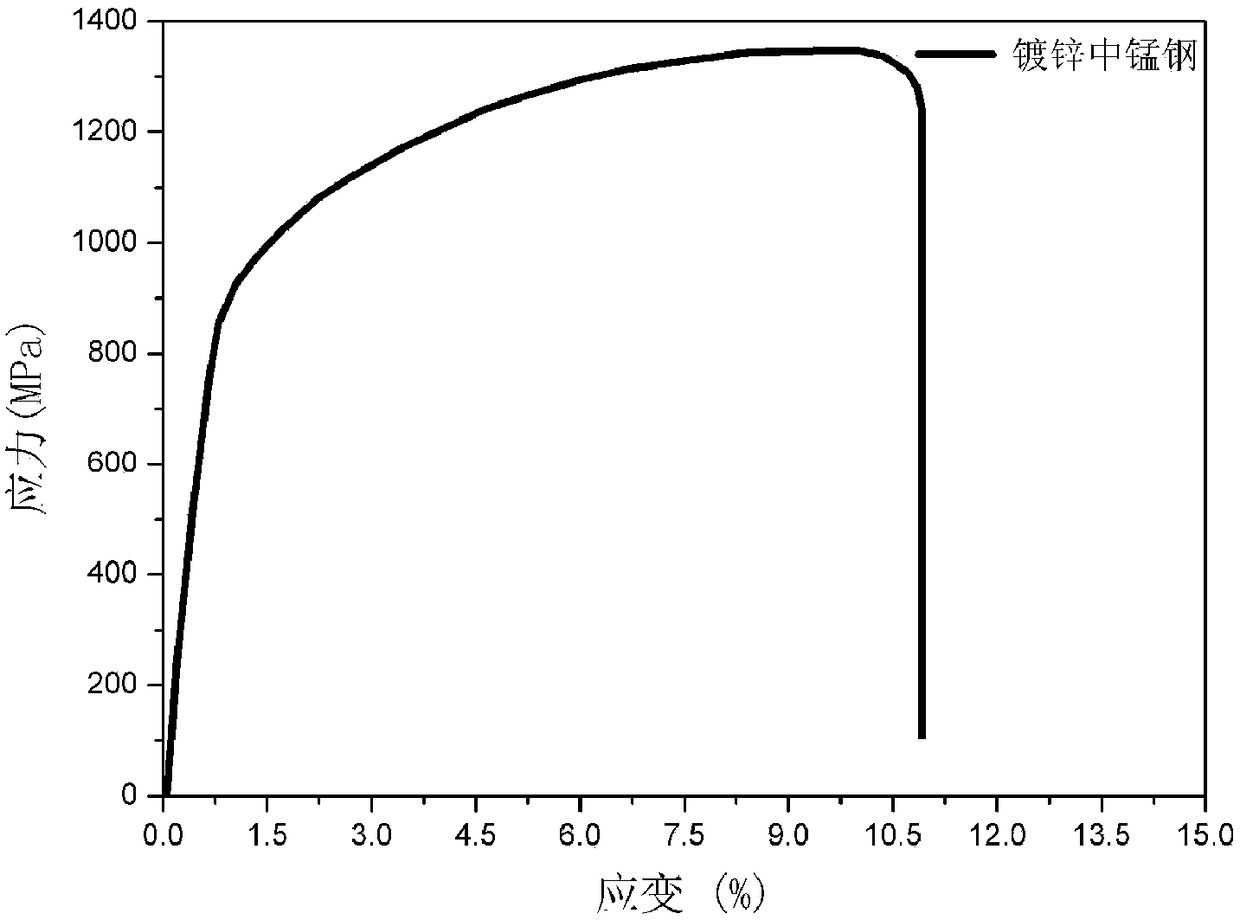

[0031] The weight percentage of the chemical composition of the selected medium manganese steel parts is: C: 0.1%; Mn: 5.0%; Al: 0.06%; P: 0.013%; S: 0.01%, the rest is Fe and inevitable impurities; It can be seen from the curve that the high-strength steel M s The point is around 310°C.

[0032] The preparation method comprises the following steps:

[0033] S1, making the medium manganese steel plate of the above composition into a steel piece for use;

[0034] S2. Heat the steel piece to be used to 850°C in a vacuum heating furnace and keep it warm for 4 minutes; in the cooling chamber where the protective gas is nitrogen, cool the steel piece to 500°C at a cooling rate of 20°C / s;

[0035] S3. Put the steel parts to be used into the constant temperature galvanizing tank, the temperature in the tank is 500°C, and keep warm for 50s;

[0036] S4. After the galvanizing is finished, the steel parts to be used are thermally dried and transferred to the mold. According to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com