Water-based environment-friendly acrylic ester paint with low smell and formaldehyde decomposition performance

A technology for decomposing acrylate and formaldehyde, which is applied in the field of environmentally friendly acrylate coatings and water-based environmentally friendly acrylate coatings, can solve the problems of formaldehyde release, endanger human health, and affect a long period of time, so as to improve gas adsorption, improve water solubility, and improve Paintable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

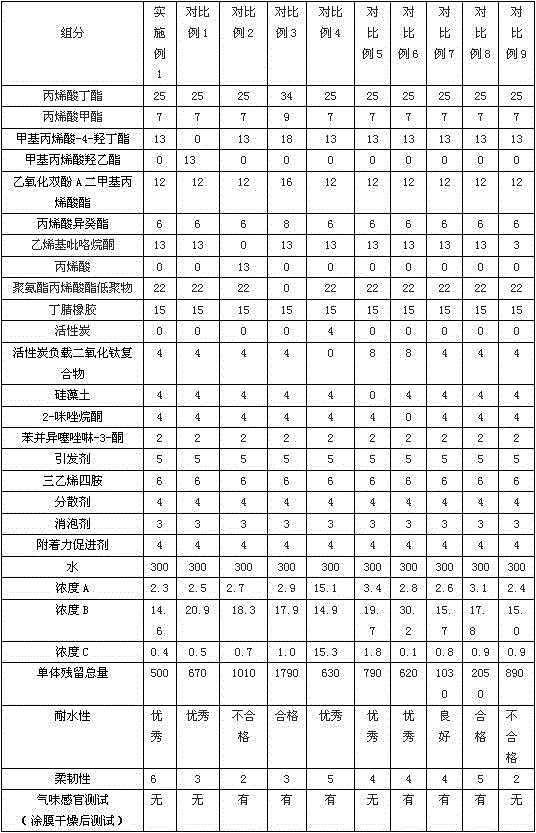

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

[0026] Specific general preparation method (unless otherwise specified, this method is used in the examples and comparative examples) :

[0027] The method for preparing the water-based environment-friendly acrylic paint with low odor and formaldehyde decomposability specifically comprises the following steps:

[0028] (1) Add acrylate monomer to the solvent water, solubilize the monomer and half of the initiator. After heating for 1 hour, add the other half of the initiator and continue the reaction for 3 hours.

[0029] (2) Add oligomer and toughening resin to the system in step (1) and stir evenly.

[0030] (3) Odor adsorbent and formaldehyde treatment agent are pre-mixed evenly, added to the system of step (2), and then triethylenetetramine is further adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com