Method of preparing homogenesis composite film by spiral fiber in coconut fiber and its application

A technology of coconut husk fiber and composite membrane, which is used in the field of preparing homogeneous composite membranes and uses from spiral fibers in coconut husk fibers, can solve problems such as separation of tube fibers in coconut husk fibers, and achieve excellent mutual adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

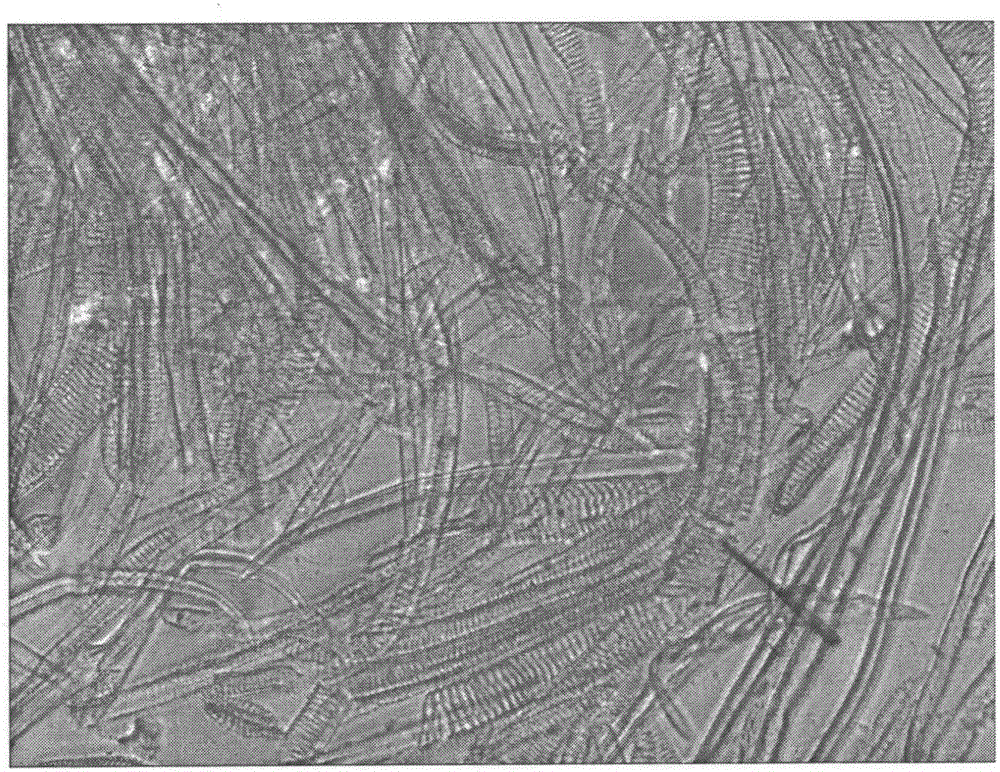

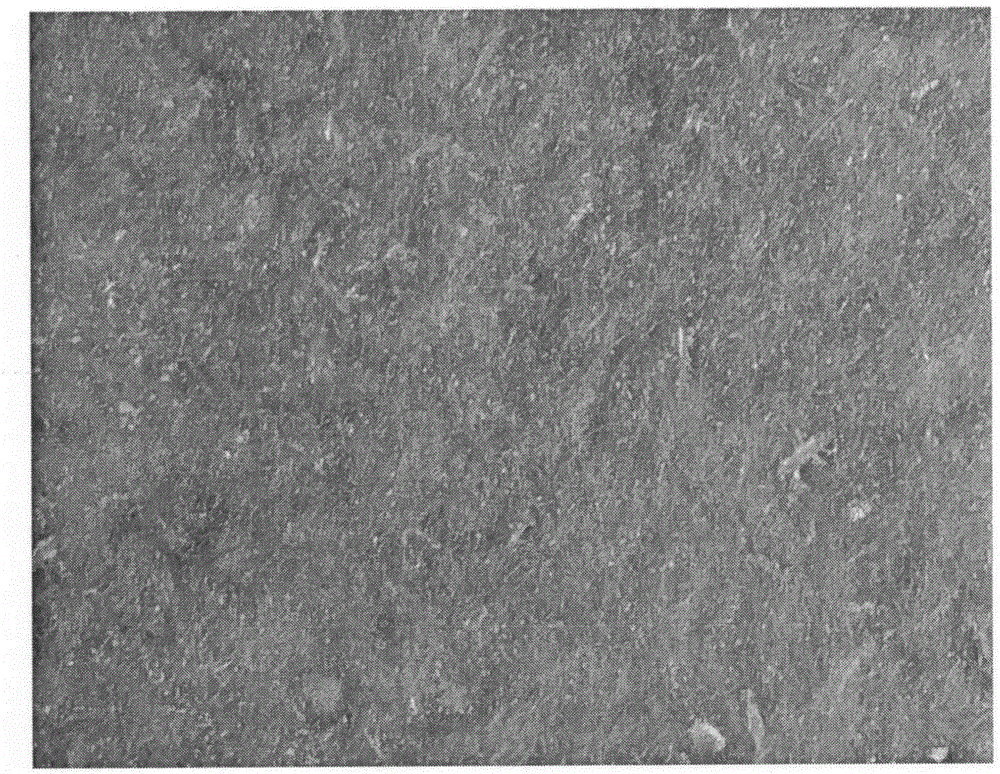

Image

Examples

Embodiment 1

[0037] A method for preparing a homogeneous composite membrane with helical fibers in coconut shell fibers, the specific steps are:

[0038] (1) Opening and removing impurities, scouring and swelling, and cleaning and removing impurities: the coconut shell is opened by mechanical striking, rubbing and pulling, and the particulate impurities are removed to obtain loose fiber clusters; the resulting fiber clusters are scoured, Washing and squeezing to remove water, the specific steps of scouring, washing and squeezing to remove water include placing the fiber mass in a beaker, completely submerging it in water, and placing it in a water bath at 60°C for simmering and swelling for 1 hour , stirring at a speed of 800rpm while scouring, after scouring, a multistage roller device is used to extrude the fiber mass to remove water, wash with water, and then extrude to remove water; the scouring, washing and extruding to remove water are carried out in a cycle 2 times, to remove the in...

Embodiment 2

[0044] A method for preparing a homogeneous composite membrane with helical fibers in coconut shell fibers, the specific steps are:

[0045] (1) Opening and removing impurities, scouring and swelling, and cleaning and removing impurities: the coconut shell is opened by mechanical striking, rubbing and pulling, and the particulate impurities are removed to obtain loose fiber clusters; the resulting fiber clusters are scoured, Washing and squeezing to remove water, the specific steps of scouring, washing and squeezing to remove water include placing the fiber mass in a beaker, completely submerging it in water, and placing it in a water bath at 80°C for swelling for 1.5 hours , stirring at a speed of 600rpm while scouring, after scouring, a multi-stage roller device is used to extrude the fiber mass to remove water, wash with water, and then extrude to remove water; the scouring, washing and extruding to remove water are circulated 3 times, after that, place in an oven at 80°C a...

Embodiment 3

[0051] A method for preparing a homogeneous composite membrane with helical fibers in coconut shell fibers, the specific steps are:

[0052] (1) Opening and removing impurities, scouring and swelling, and cleaning and removing impurities: the coconut shell is opened by mechanical striking, rubbing and pulling, and the particulate impurities are removed to obtain loose fiber clusters; the resulting fiber clusters are scoured, Washing and squeezing to remove water, the specific steps of scouring, washing and squeezing to remove water include placing the fiber mass in a beaker, completely submerging it in water, and placing it in a water bath at 98°C for swelling for 1 hour , stirring at a speed of 400rpm while scouring, after scouring, a multi-stage roller device is used to extrude the fiber mass to remove water, wash with water, and then extrude to remove water; the scouring, washing and extruding to remove water are circulated 4 times, after that, place it in an oven at 80°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com