Igniter reagent of airbag device and preparation method of igniter reagent

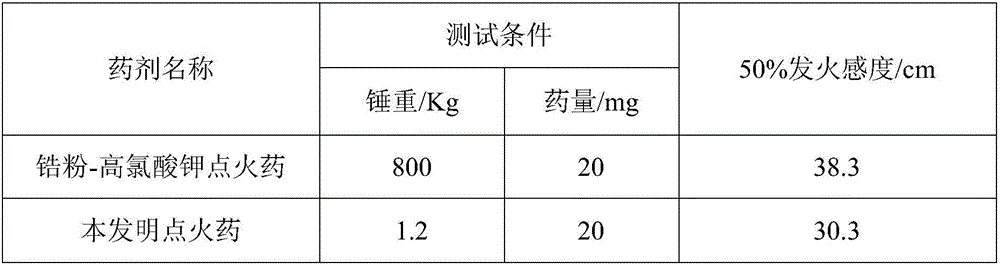

A technology for an airbag device and an ignition device, which is applied to ignition agents, offensive equipment, etc., can solve the problems of high cost, safety risks, and high ignition powder sensitivity, and achieves low cost, low price, and low electrostatic spark sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

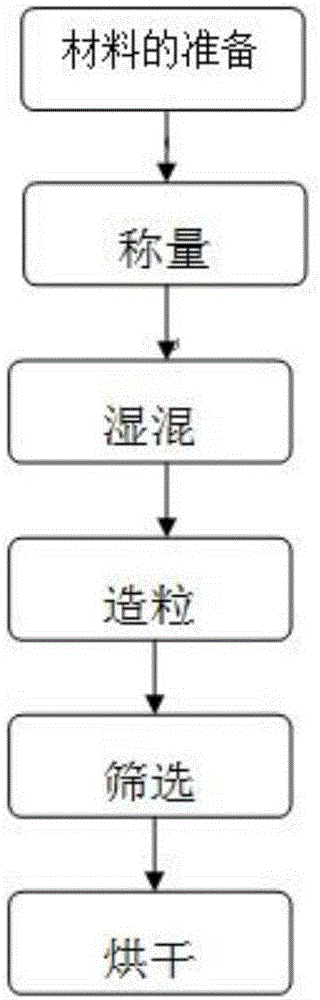

[0027] To prepare an igniter potion:

[0028] Weigh 45% of titanium hydride with a particle size of less than 10 μm and a hydrogen content of less than 2%, 53% of potassium perchlorate with an average particle size of less than 20 μm, 1.8% of glucose with a particle size of less than 10 μm, and 0.2% of fluororubber. The solvent is acetone. First pour the fluororubber into the wet mixing granulator, turn on the stirring paddle, stir slowly, then pour the titanium hydride into the equipment, wait for the titanium hydride powder to be completely wet, then add potassium perchlorate and glucose in sequence, and finally add acetone , increase the speed of the stirring paddle, stir for 15 minutes, turn on the cutting knife, and run for 15 minutes, wait until the medicine turns into a ball, stop the equipment, and discharge. Pour the wet-mixed medicine into the swing granulator with CQ11 sieve, and turn on the equipment to complete the granulation. Finally, use the vibrating screeni...

Embodiment 2

[0030] To prepare an igniter potion:

[0031] The preparation method is the same as in Example 1, wherein the raw material components are: 20% titanium powder, 78% potassium chlorate, 0.5% carbon powder, 1.5% fluorine rubber, and the solvent is acetone.

Embodiment 3

[0033] To prepare an igniter potion:

[0034] The preparation method is the same as in Example 1, wherein the raw material components are: 35% titanium powder, 60% ammonium perchlorate, 1% carbon powder, 4% fluorine rubber, and the solvent is acetone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com