Rapid treatment method and treatment system for acidic industrial waste water

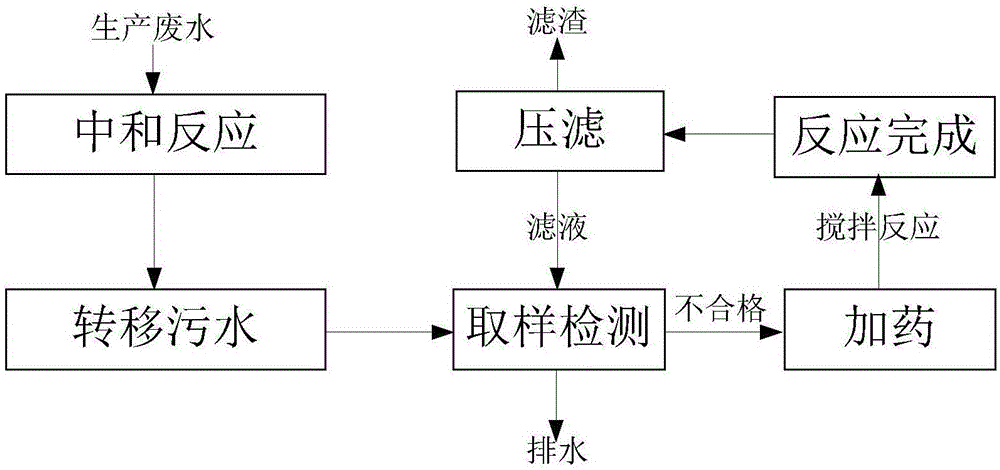

A technology for acid wastewater and treatment methods, which is applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc. The sample is not representative, etc., to achieve the effect of significant treatment effect, improved stirring efficiency, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

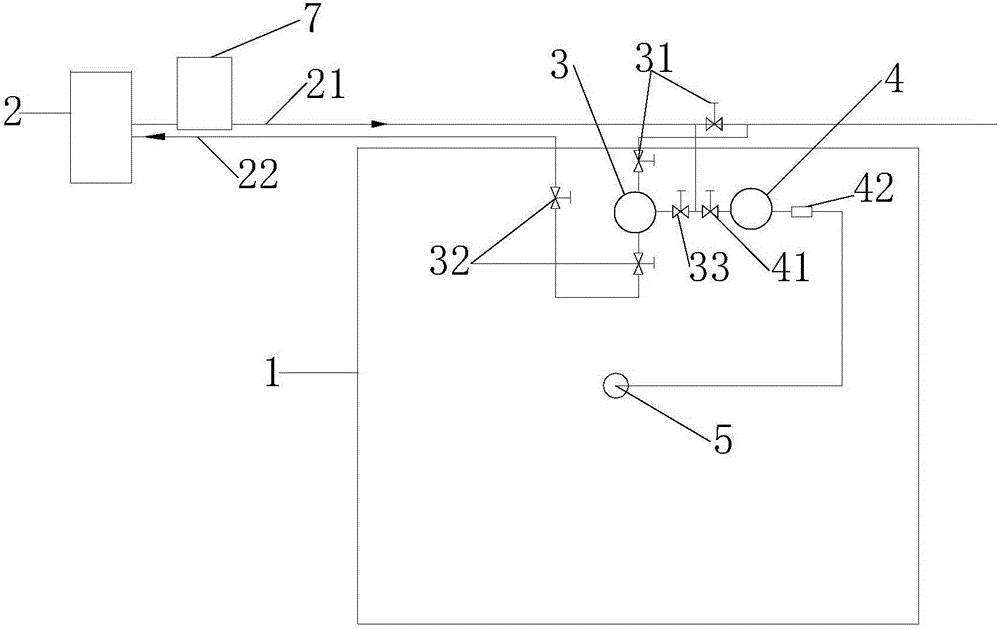

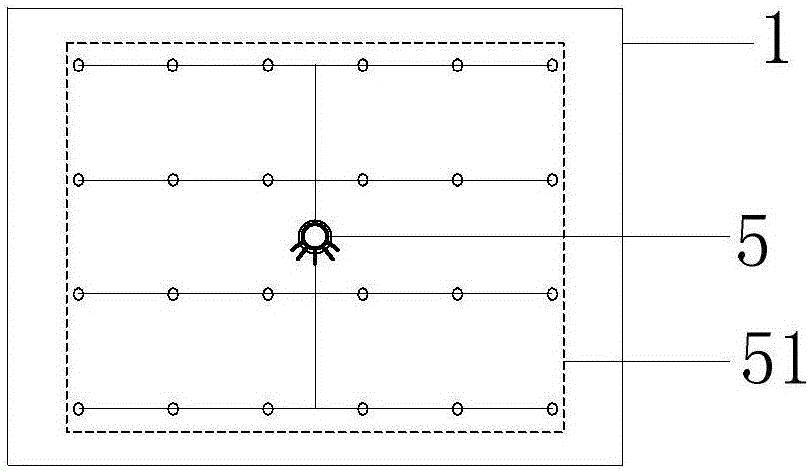

[0046] like figure 2 As shown, in 4000L and on tank 7, multiple feed pipes and discharge pipes are respectively provided, and pumps are provided on the pipes to provide power for transporting the solution; a 300m 3 In the sewage treatment pool 1, the filter press 2 is selected as the filter device, and two 3000L tanks are selected as the sampling tank 3 and the dosing tank 4 respectively.

[0047] The sampling tank 3 and the dosing tank 4 are installed on the upper part of the sewage treatment tank 1, and are connected with the sewage treatment tank with pipelines, and corresponding valves are respectively installed on the pipelines to control the flow of the solution in the pipes, wherein the sampling tank 3 It is connected with the neutralization tank 7 for collecting samples therein for detection, and the other end is connected with the sewage treatment tank 1; one end of the dosing tank 4 is connected with the medicine feeding pipeline, and the other end is dosing with th...

Embodiment 2

[0050] Adopt the device identical with above-mentioned embodiment 1, after finishing the installation of sewage treatment plant, will 4m 3 The sewage was discharged into the neutralization tank, and its pH value was found to be 3.9 through testing, in which Cu 2+ The concentration is 1300mg / L, Fe 3+ The concentration is 113mg / L and Mn 2+ The concentration is 86mg / L. The stirring device therein was turned on, and a sodium hydroxide solution with a mass concentration of 30% was added thereto until the pH of the solution reached 7.0. Discharge the neutralized solution into the sewage treatment tank, turn on the stirring device, take out the sample solution from the sampling tank for testing, and find that Cu 2+ The concentration is 8mg / L, Fe 3+ The concentration is 5mg / L and Mn 2+ The concentration is 1mg / L, and the sulfide concentration measured by the potentiometer is 0.6mg / L, which meets the relevant standards for sewage discharge. Add 3Kg of activated carbon to the sewag...

Embodiment 3

[0052] Adopt the device identical with above-mentioned embodiment 1, after finishing the installation of sewage treatment plant, will 4m 3 The sewage was discharged into the neutralization tank, and its pH value was found to be 2.3 through testing, in which Cu 2+ The concentration is 21000mg / L, Fe 3+ The concentration is 513mg / L and Mn 2 + The concentration is 486mg / L. The stirring device therein was turned on, and a sodium hydroxide solution with a mass concentration of 30% was added thereto until the pH of the solution reached 8.9. Discharge the neutralized solution into the sewage treatment tank, turn on the stirring device, take out the sample solution from the sampling tank for testing, and find that Cu 2+ The concentration is 52mg / L, Fe 3+ The concentration is 31mg / L and Mn 2+ The concentration is 4mg / L, gradually add sodium sulfide solution with a mass concentration of 5% to the dosing tank, and evenly add it to the surface of the sewage treatment tank through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com