Device for replacing loop steel wire rope of cold rolled galvanizing production line and use method of device

A wire rope and production line technology, applied in hoisting devices, spring mechanisms, etc., to achieve the effects of avoiding oil pollution, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

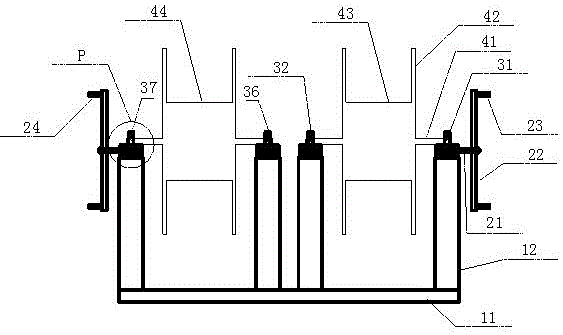

[0036] The device for replacing the looper wire rope of the cold-rolled galvanized production line of the present invention includes a stabilizer and two turntables. The length of the stabilizer is 2700mm.

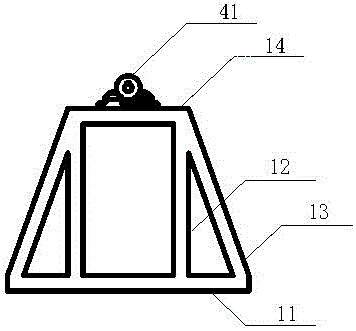

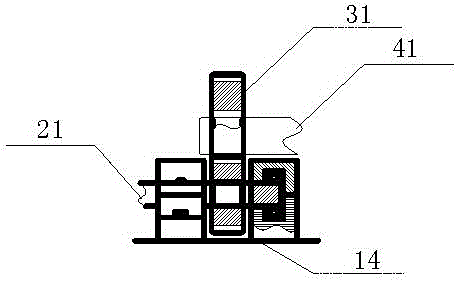

[0037] see now Figure 1-Figure 4 , figure 1 It is a structural schematic diagram of a looper wire rope replacement device according to an embodiment of the present invention, figure 2 for figure 1 side view, image 3 for figure 1 The enlarged view of the P part in Figure 4 for image 3 side view. As shown in the figure, the stabilizer includes a steel base plate on which two wire rope drum turrets arranged in a straight line and symmetrically arranged front and back are arranged on the steel base plate. The two columns 12 are perpendicular to the base plate 11, and the top of the column is provided with a column top plate 14, and is supported on both sides of the column by two diagonal struts 13; the surface of the column top plate 14 is provided with a first sh...

Embodiment 2

[0040] The device usage method of the looper wire rope replacement of the cold-rolled galvanizing production line of the present invention comprises the following steps:

[0041] a. Hoist the stabilizer frame to the operating side of the looper wire rope of the cold-rolled galvanized production line with the crane in the cold-rolled galvanized production line;

[0042]b. Insert and fix one end of the new steel rope used to replace the old steel rope of the looper in the hole provided on the first steel rope drum 43. The diameter of the new steel rope needs to match the diameter of the insertion hole, and the new steel rope is coiled on the Above the first wire rope drum 43; hoist the first bearing 33 onto the wire rope drum shaft 41 with a crane, so that the first bearing, the second bearing and the third bearing are arranged in a font shape, wherein: the second bearing and the third bearing are spaced left and right Arrangement, the first bearing is close to each other above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com