Novel heavy truck car hub unit

A new type of technology for automobile wheels, applied in the field of automobile parts, can solve the problems of unqualified assembly clearance, easy falling off of the inner ring, poor sealing performance, etc., to achieve aggravated ablation damage, simplified assembly process, and simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

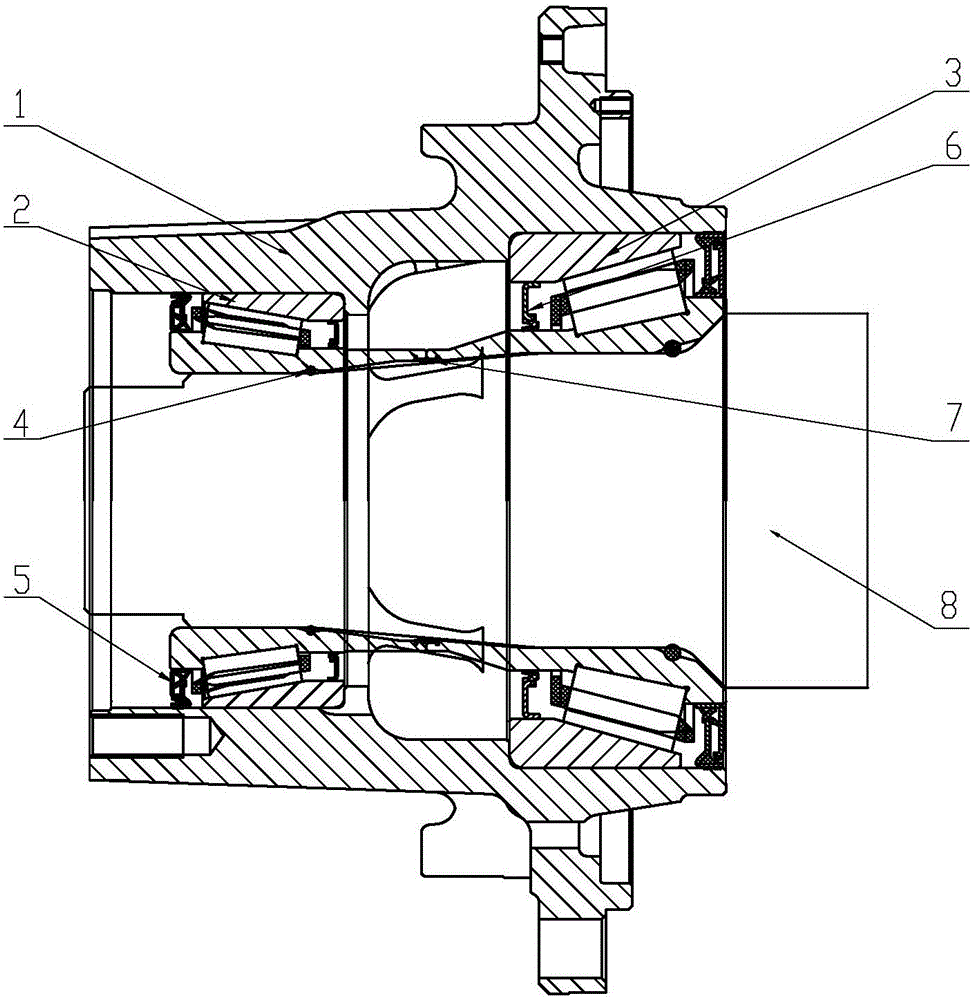

[0026] Such as figure 1 As shown, a new type of heavy truck hub unit mainly includes a hub 1, a first bearing 2 and a second bearing 3, the first bearing 2 and the second bearing 3 are respectively located at both ends of the hub 1, the first bearing 2 and the second bearing 3 contain a cage, inner and outer rings and a number of rolling elements.

[0027] The inner right end of the hub 1 is sequentially provided with a combined sealing ring 6, an O-ring 4, a single sealing ring 5, a single sealing ring 5, an O-ring 4, and a combined sealing ring 6 from right to left, and the combined sealing ring 6 is located at the first Between the large rib of the inner ring of the bearing 2 and the second bearing 3 and the inner cavity of the hub 1, the single seal ring 5 is located between the inner and outer rings of the first bearing 2 and the second bearing 3, and the O-ring 4 is located in the first bearing 2 And between the inner ring of the second bearing 3 and the shaft 8 . Wher...

Embodiment 2

[0031] A new type of wheel hub unit for heavy trucks, mainly including a hub 1, a first bearing 2 and a second bearing 3, the first bearing 2 and the second bearing 3 are respectively located at both ends of the hub 1, the first bearing 2 and the second bearing 3 are both Contains a cage, inner and outer rings and several rolling elements.

[0032] The inner right end of the hub 1 is sequentially provided with a combined sealing ring 6, an O-ring 4, a single sealing ring 5, a single sealing ring 5, an O-ring 4, and a combined sealing ring 6 from right to left, and the combined sealing ring 6 is located at the first Between the large rib of the inner ring of the bearing 2 and the second bearing 3 and the inner cavity of the hub 1, the single seal ring 5 is located between the inner and outer rings of the first bearing 2 and the second bearing 3, and the O-ring 4 is located in the first bearing 2 And between the inner ring of the second bearing 3 and the shaft 8 . Wherein, ther...

Embodiment 3

[0036] The difference from the first two embodiments of embodiment 1 and embodiment 2 is that the type of rolling elements in the present invention is a cylindrical roller.

[0037] In the new heavy-duty truck hub unit disclosed by the present invention, the seal between the first bearing 2 and the second bearing 3 and the hub 1 is assembled and sealed by a combined seal 6 with rubber at the top, and the outer side of the labyrinth combined seal 6 is connected to the hub. The inner side of 1 is in close contact, and the inner side of the combined seal 6 is in close contact with the large ribs of the inner rings of the first bearing 2 and the second bearing 3, so that a closed seal is formed between the first bearing 2, the second bearing 3, the combined seal 6 and the hub 1 The grease circulation system can not only prevent oil leakage, but also prevent external dust from entering, thus prolonging the service life of the hub unit.

[0038] In the new heavy-duty truck hub unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com