A plastic molding mold for a cylinder and its side irregular three-headed spiral groove

A plastic molding and spiral groove technology, which is applied in the field of cylindrical and spiral groove forming molds, can solve the problems of workpiece burrs, low efficiency, and poor quality, and achieve the effects of precise size, less processing procedures, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

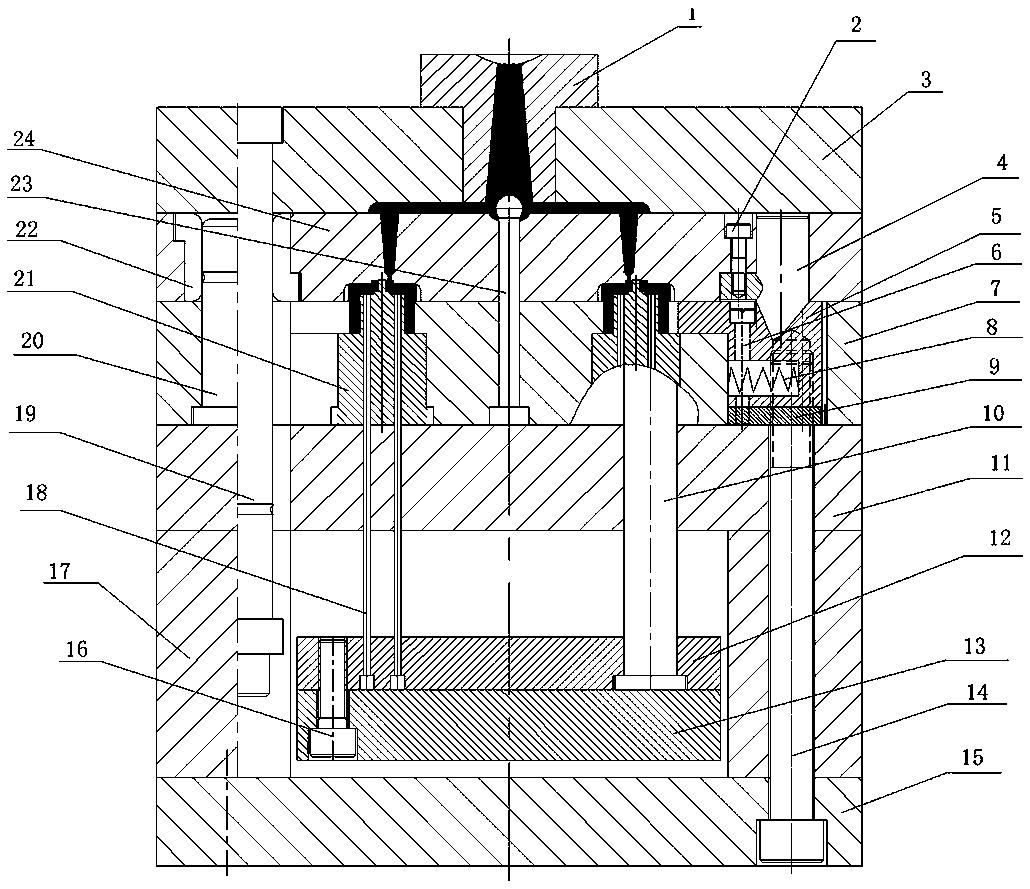

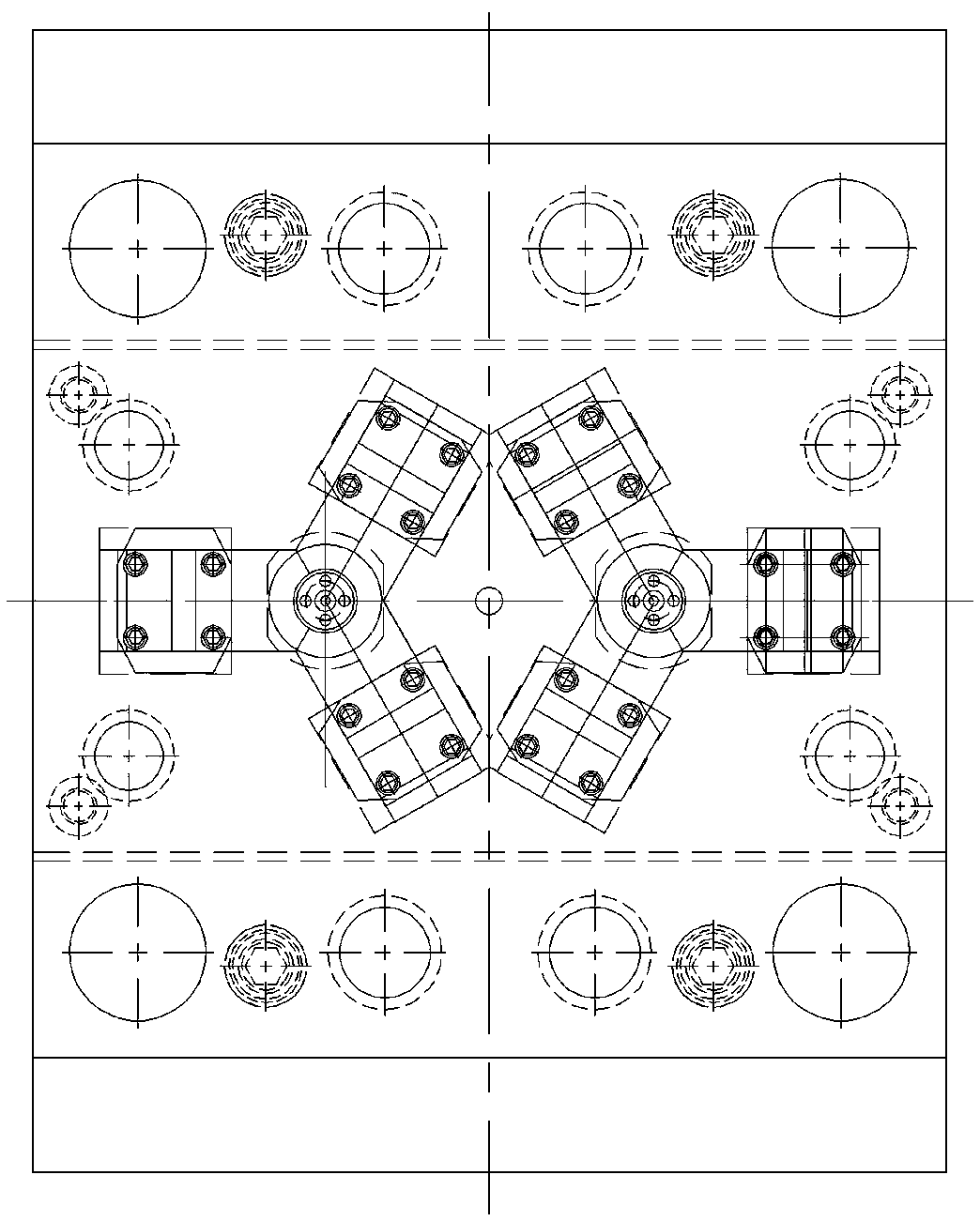

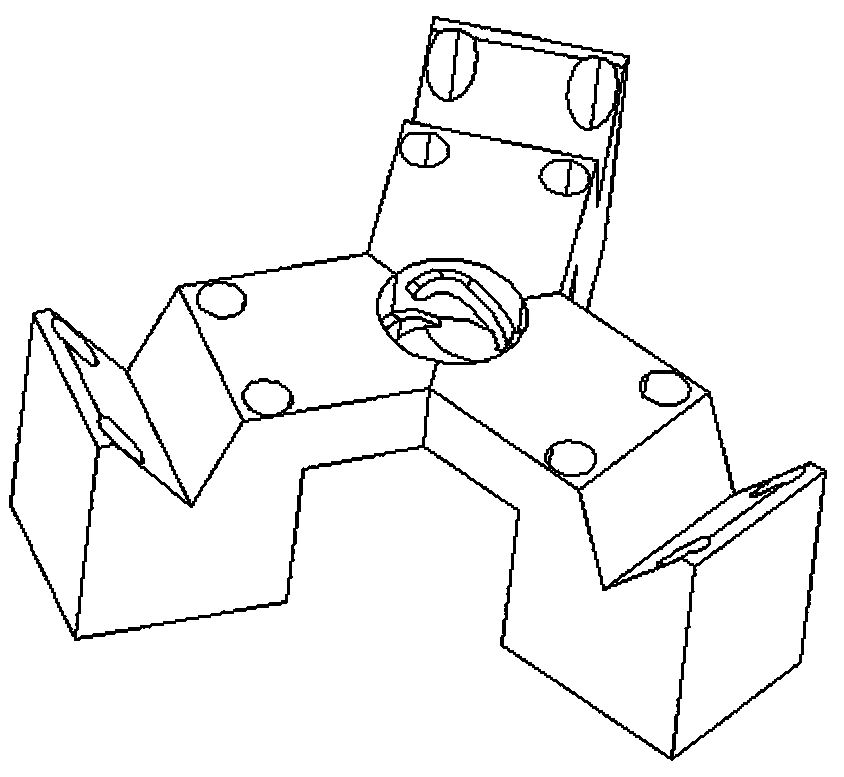

[0023] Such as Figure 1~5 As shown, the present invention mainly comprises fixed mold and movable mold, and wherein, fixed mold comprises upper mold base 3 and fixed cavity plate 24; mechanism.

[0024] In the fixed mould, the upper mold base 3 is connected with the molding equipment, the fixed cavity plate 24 is arranged in parallel with the upper mold base 3, and the two are connected through the drawing plate guide post 19, so that after the injection molding is completed, the drawing plate guide post 19 makes the The upper mold base 3 is separated from the fixed cavity plate 24 . The cavity-fixing plate 24 is provided with an oblique guide post 4, runners and two vertically symmetrical molding cavities, the lower end of the oblique guide post 4 is V-shaped, and it is fixedly connected to the cavity-fixing plate 24 via the first screw 2. . The inclined guide post 4 moves and presses the slide block 5 to ensure the accuracy of the shape and size of the formed workpiece. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com