Crane lazy arm profile primary forming unit

A technology for forming units and cranes, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low manufacturing efficiency and precision, and achieve the effects of improving efficiency and quality, simple structure and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a one-time molding unit for crane arm profiles, which is simple in structure and easy to use. The whole processing process truly realizes automation, intelligence and continuity, and improves the efficiency and quality of production. In the processing process, various coefficients can be adjusted. Adjustable, suitable for processing of different sizes, more adaptable.

[0023] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

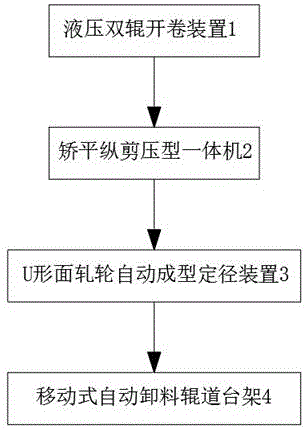

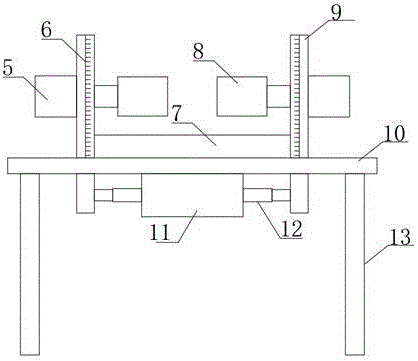

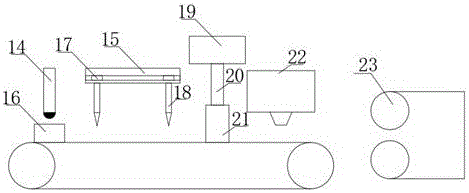

[0024] Such as Figure 1-Figure 5 As shown in the figure, a crane arm profile forming unit includes a hydraulic double-roller uncoiling device 1, a leveling and longitudinal shearing and pressing machine 2, a U-shaped surface rolling wheel automatic forming and sizing device 3, and a mobile automatic unloading roller table The platform 4, the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com