Finished bearing spraying and flushing device

A technology for flushing devices and bearings, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems that affect the cleaning effect of finished bearings, the bearings cannot be shaken, and the water tank is fixed, etc. The effect of promoting the utilization value, preventing collision, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

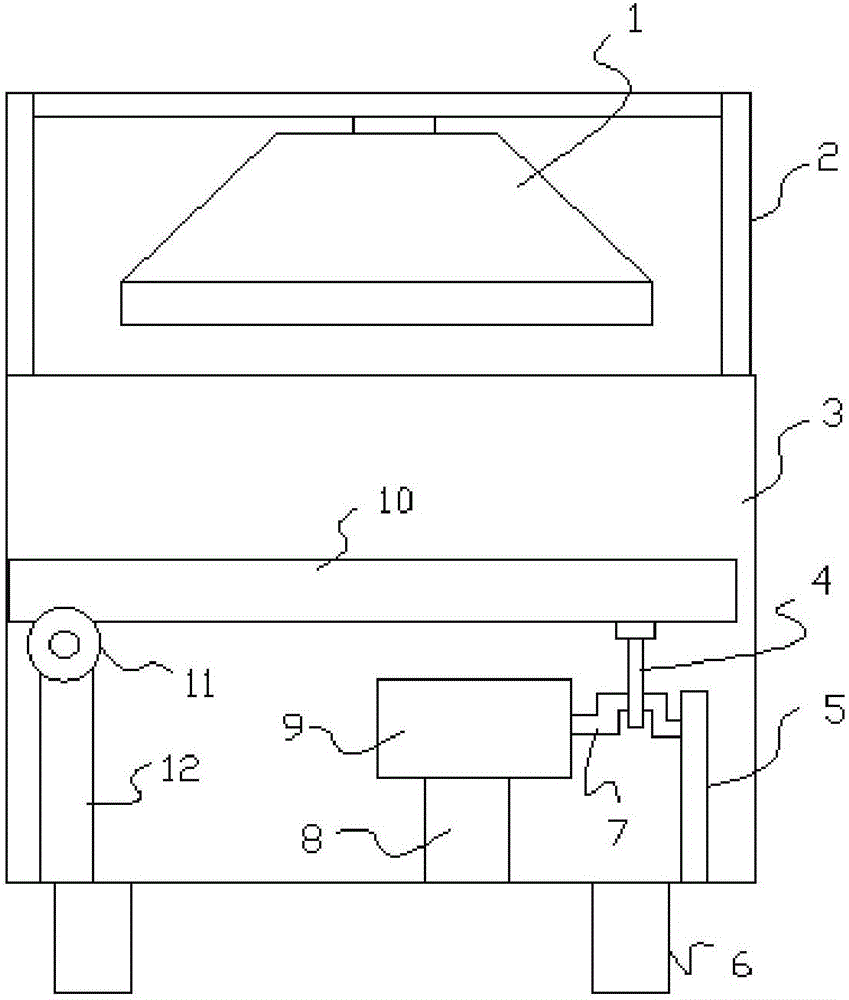

[0019] Such as figure 1 , figure 2 As shown, the structure of this kind of finished bearing spray washing device includes a washing box 3 and legs 6 at the bottom. The top of the washing box 3 is fixed with a spray head 1 through a bracket 2 . When in use, bearings can be placed in the flushing box, and the spray head can spray cleaning liquid to prepare for the cleaning of the finished bearings later.

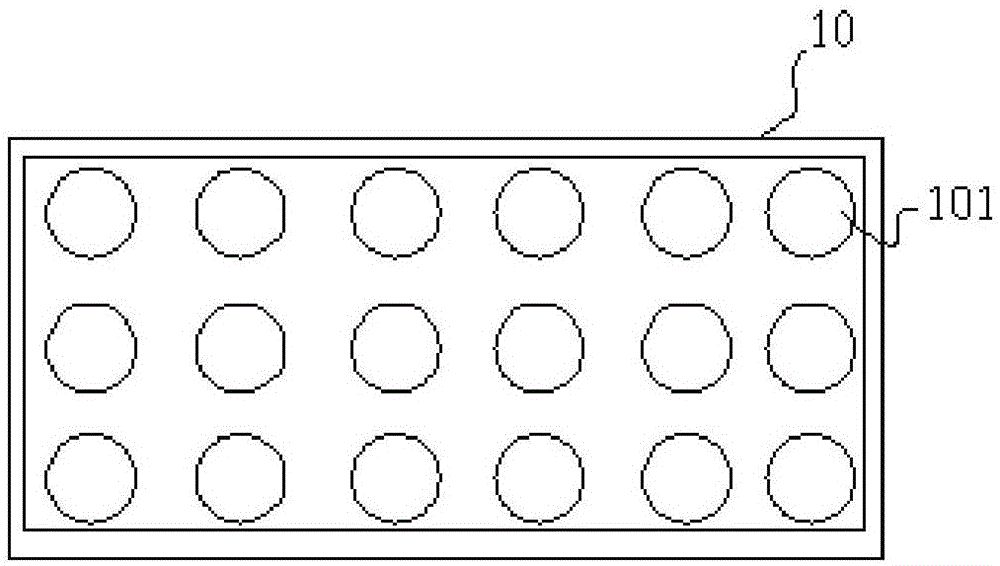

[0020] In the above embodiment, specifically, a flushing tank 10 is arranged horizontally inside the flushing tank 3, the bottom of the left end of the flushing tank 10 is hinged with the support rod 12 at the bottom through the first hinge shaft 11, and the right end The bottom is hinged with the upper end of the connecting rod 4 through the second hinge shaft (not marked in the figure), the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com