Catalytic agent screening system and method

A catalyst and screening technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problems of high labor cost, high labor intensity, human hazards, etc., and improve economic benefits , cost reduction, highly targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

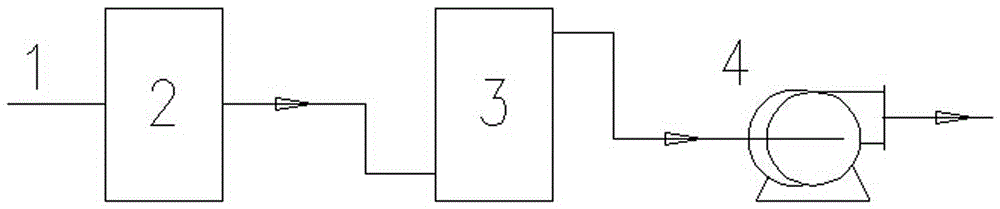

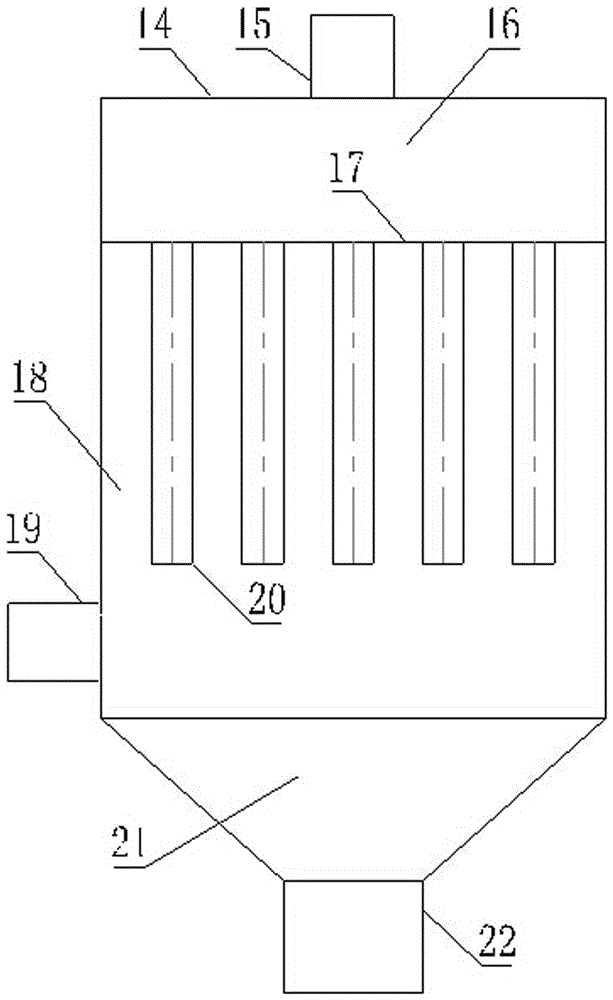

[0024] A method for carrying out catalyst screening, specifically comprising the following steps; as figure 1 As shown, the blower 4 is turned on to generate negative pressure. Under the action of negative pressure and higher air velocity wind force, the rubber hose 1 transports the catalyst of the converter, and first enters the catalyst separation device 2 for the separation of the catalyst and the catalyst powder. The separation of other impurities completes the sieving and collection of the catalyst. The catalyst powder and other impurities are transported to the catalyst powder collection device 3 under the action of negative pressure and high gas velocity wind force. After filtration, the catalyst powder and the gas are separated. The collection and recovery of the catalyst powder is completed, and the gas is filtered and discharged through the fan 4.

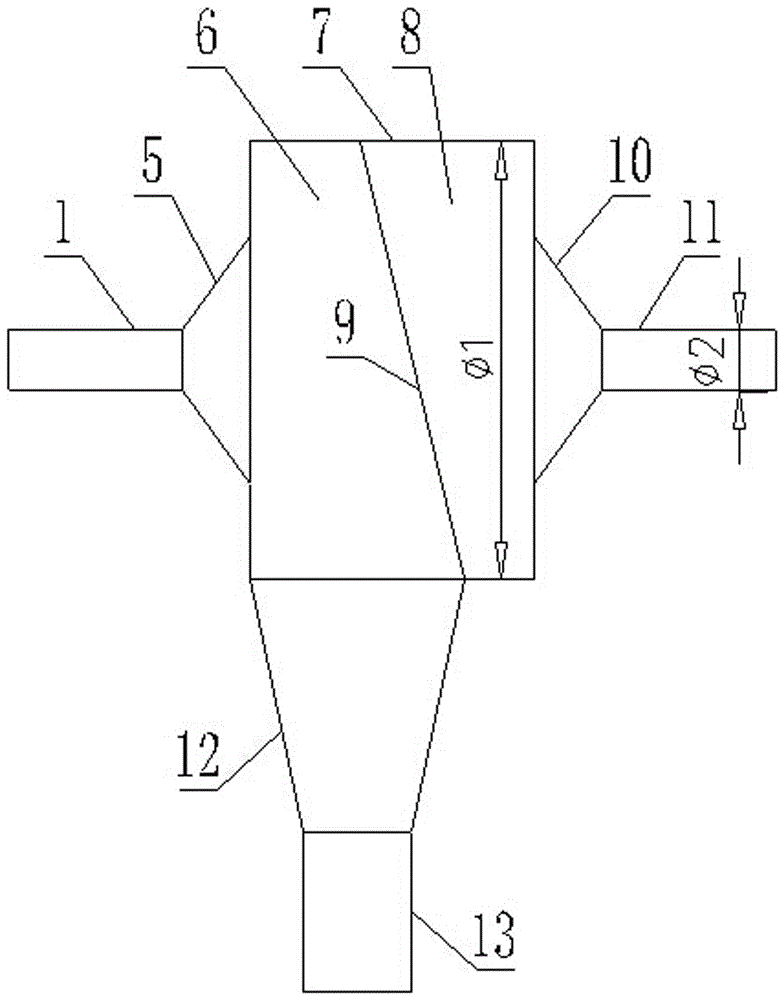

[0025] like figure 2 As shown, the catalyst separation device is further explained: under the action of negative pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com