Materials and sundries clearing device and method thereof

A technology for sundries and materials, applied in the field of devices for removing materials and sundries, can solve problems such as a large number of sundries, and achieve the effects of high removal rate, reduced maintenance cost, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

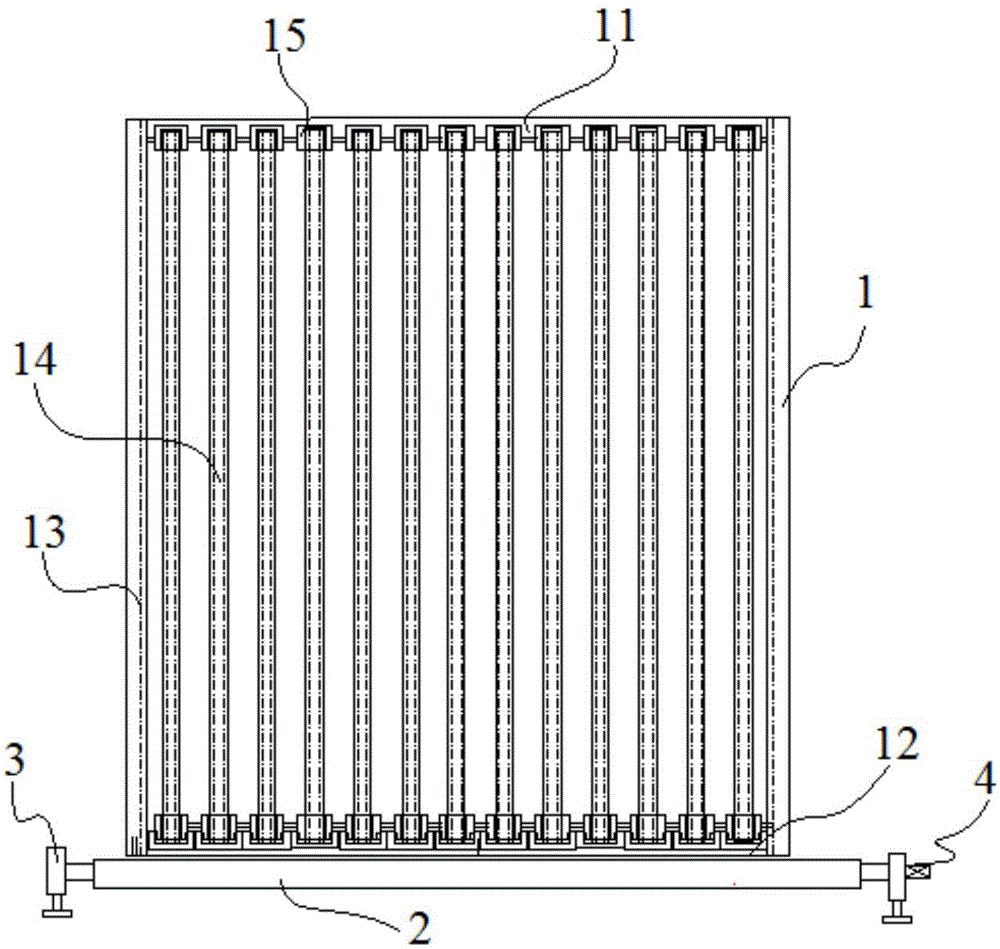

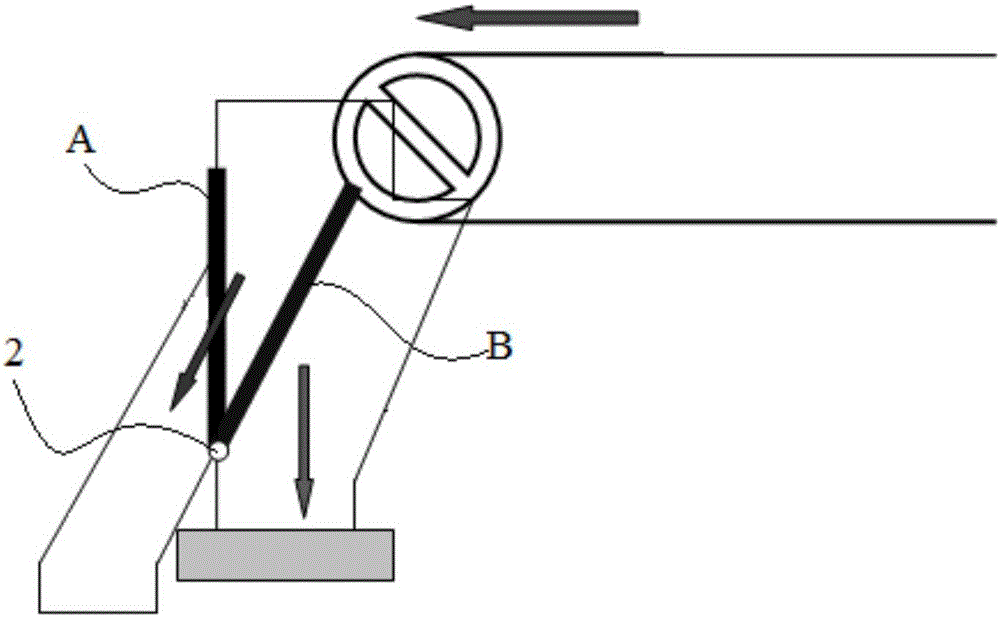

[0041] combine Figure 1-2 , a device for removing material and debris in this embodiment includes a screen 1, wherein the screen 1 includes a screen bar 14, a sleeve 11, a base 12 and a frame 13, the screen 1 is located in the hopper, and the upper part of the screen 1 is located Below the upper belt, that is, below the scraper blade of the upper belt head pulley, such as figure 2 As shown; the bottom of the screen 1 is provided with a transmission shaft 2, and the transmission shaft 2 is connected with the transmission connecting rod 4, as figure 1 shown.

[0042] Below the base 12 of screen cloth 1 is provided with inclined chute, and inclined chute is positioned at the outside of hopper, as figure 2 As shown, when the screen cloth 1 is not in use, the plane where the screen cloth 1 is located is in the vertical direction.

[0043] The two ends of the transmission shaft 2 are connected with the bearing seat 3, the bearing seat 3 is located on the hopper, the transmissi...

Embodiment 2

[0050] A kind of method for removing material sundries of the present embodiment, comprises the following steps:

[0051] Step A, build the above-mentioned a kind of device for removing material and sundries, the screen 1 is in a vertical state;

[0052] Step B, the motor runs to drive the transmission connecting rod 4;

[0053] Step C, the transmission connecting rod 4 simultaneously drives the transmission shaft 2 to move;

[0054] Step D, the transmission shaft 2 and the screen 1 are connected through the base 12, the bearing seat 3 drives the base 12 to move, and the angle between the plane where the screen 1 is located and the horizontal direction changes;

[0055] Step E, the screen 1 continues to move and touches the support block in the hopper, or after the transmission connecting rod 4 reaches the position of the limit switch, the limit switch sends a signal to the motor, the motor stops running, and the transmission connecting rod 4 and the transmission shaft 2 and...

Embodiment 3

[0061] A device for removing material debris in this embodiment is installed at the head wheel of the incoming material belt. The upper part of the screen 1 is below the scraper of the upper belt head wheel, and the lower part is at the front of the hopper. The angle between the plane where the screen 1 is located and the horizontal direction is 75°, the lower part of the screen 1 passes through the inclined chute, and the sundries can be introduced into the belt platform below, and the holes are drilled at the platform position with a length of 1200mm * a width of 650mm, and the sundries are led to the first floor, and the sundries are transported regularly every week.

[0062] Such as figure 2 As shown, the mark A indicates the position of the screen 1 when it is not in use, and the mark B indicates the position of the screen 1 when it screens out the sundries in the incoming material; When passing through the screen 1, the debris enters the debris pile through the inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com