Grille grid

A grid and grid technology, applied in the field of crushers, can solve the problems of high maintenance cost and poor wear resistance of the grid, and achieve the effects of simple maintenance and operation, reducing the wear area and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

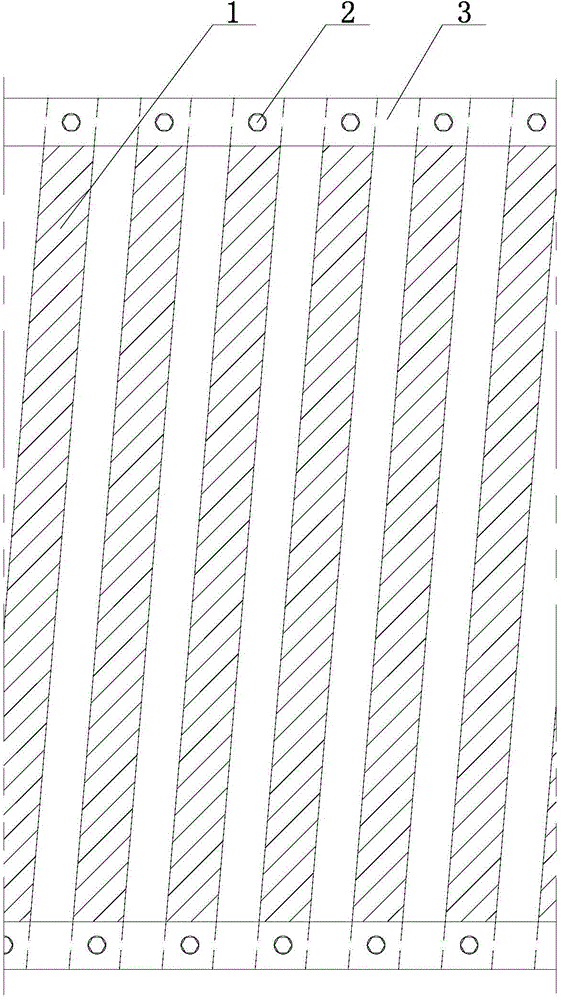

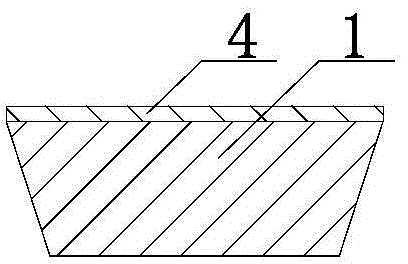

[0012] Such as figure 1 , 2 As shown, the grid bar of this grid includes a grid bar body 1, and the grid bar body 1 is fixed on the grid outer frame 3 by fasteners 2. The upper surface of the grid bar body 1 is provided with a wear-resistant layer 4, and the grid bar body 1 The cross section is inverted trapezoidal.

[0013] Since the cross-section of the grid body 1 is an inverted trapezoid, when a qualified ore block passes through the grid, it is difficult to touch the left and right sides of the grid body 1, which reduces the wear area, and the upper surface of the grid is equipped with Wear-resistant layer 4, when the ore block falls on the upper surface of the grid body 1, under the protection of the wear-resistant layer 4, the grid body 1 is not easy to wear, thus greatly prolonging the service life of the grid and reducing maintenance cost.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com