Electric welding protecting mask

A face mask and jaw mask technology, applied in eye mask, ophthalmic surgery, etc., can solve the problem of lack of bright light, and achieve the effect of protecting eyes and good observation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to further describe the technical features and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

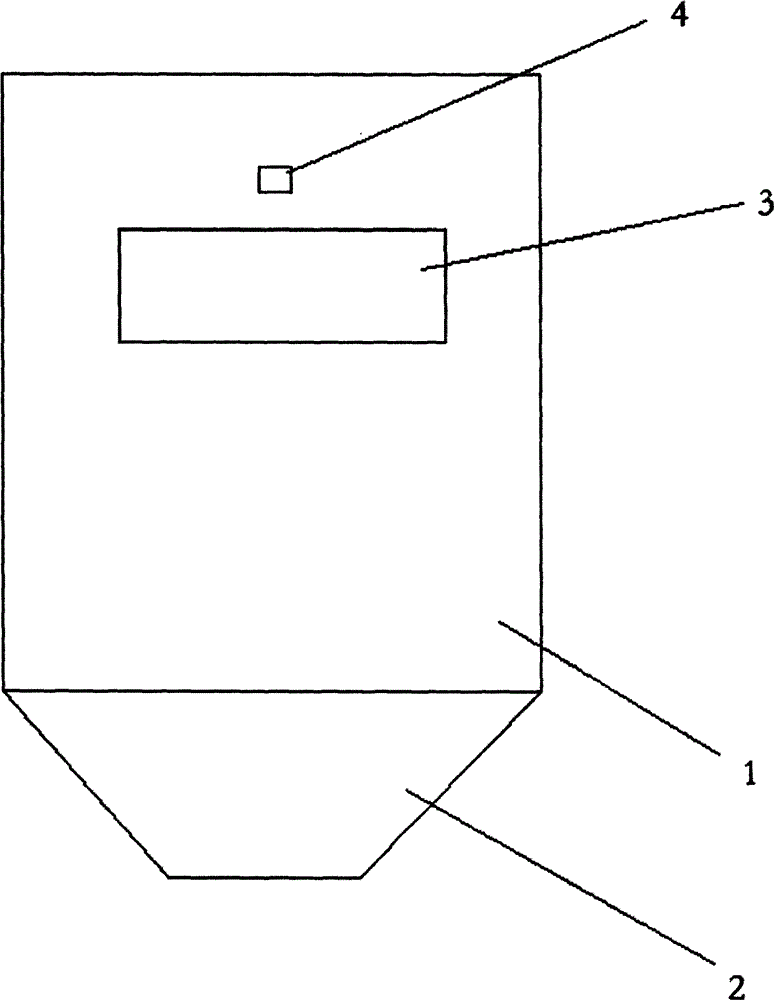

[0009] refer to figure 1 and figure 2 , electric welding protective mask, including a mask 1 and a chin cover 2, the chin cover 2 is arranged below the mask 1, integrally formed with the mask 1, the upper part of the mask 1 is provided with an observation area 3, and the top of the observation area 3 is provided with a photoreceptor 4. The observation area 3 is provided with a colorless transparent glass 5, a glass chamber 8 is provided below the observation area 3 in the mask 1, a number of colored glasses 6 are arranged in the glass chamber, and a drive is arranged above the observation area 3 in the mask 1. The motor 9 is provided with a connecting rod 7 below the driving motor 9, and one end of the connecting rod 7 is connected with the driving motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com