Chitosan tofu and preparation method thereof

A technology of chitosan and tofu, applied in the field of food processing and manufacturing, can solve the problem of poor taste of tofu, and achieve the effects of good taste, good edible value and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Tofu preparation method provided by the present invention, overall technological process is:

[0082] Raw soybeans→cleaning→soaking→rinsing→refining→raw pulp→cooking pulp→pointing brain→squatting brain→top brain→press molding→packing and cooling→finished product, the specific preparation steps are as follows.

[0083] (1) Choose soybeans with full grain weight, no impurities, no insect eyes, and no moldy deterioration, wash them, soak them at 20°C for 12-18 hours until the soybeans have no hard core, and ensure that the soybeans fully absorb water; the quality of soybeans after absorbing water is the same as before soaking 2 to 2.5 times the dry mass of soybeans; rinse with clean water 3 times after soaking.

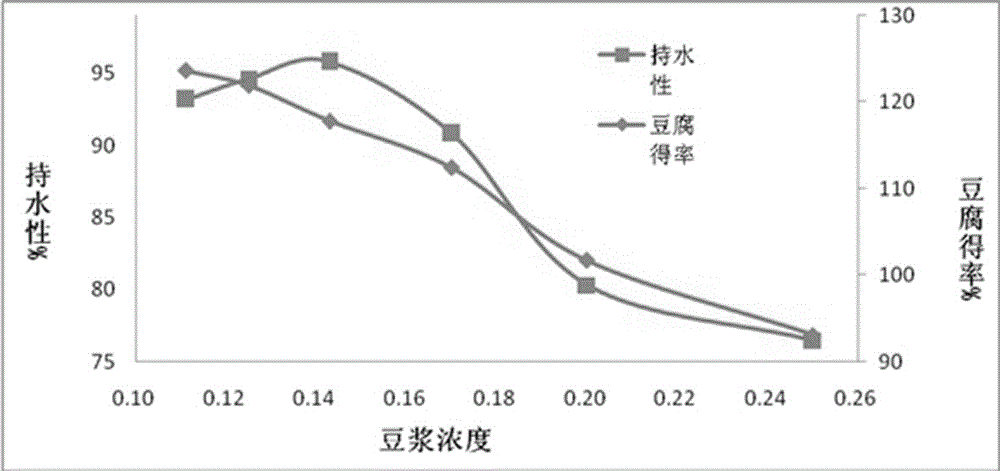

[0084] (2) Beat the soaked soybeans and water according to a certain ratio, so that the total water consumption is 8 times that of dry beans, boil the soybean paste at about 95°C, and keep it for 5 minutes, then separate the pulp and slag, and collect the slurry f...

Embodiment 2

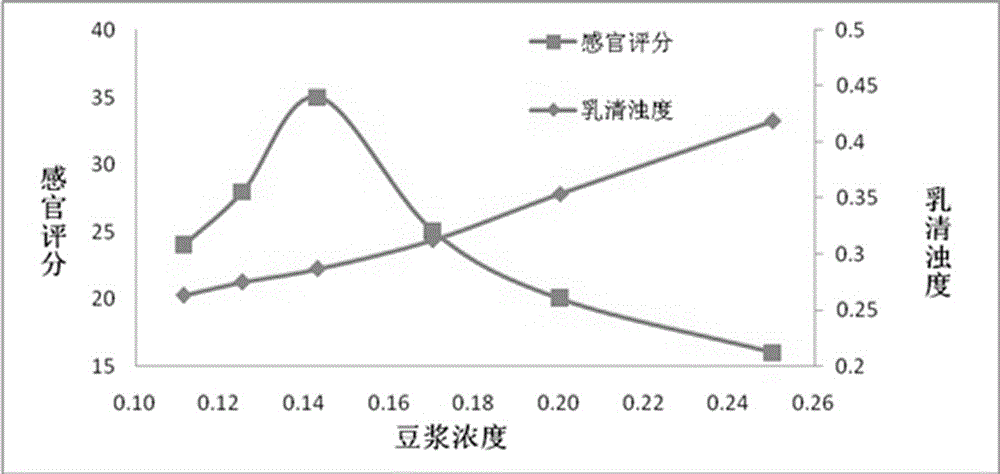

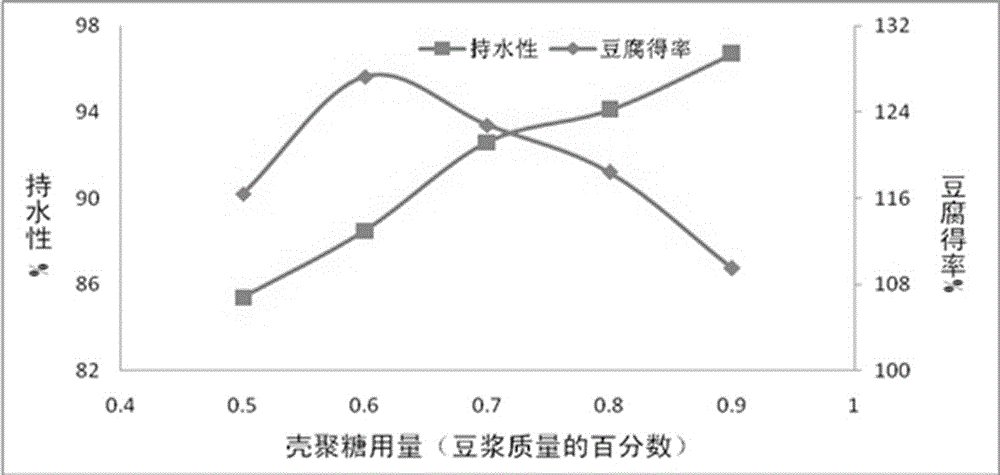

[0116] On the basis of Example 1, the inventors conducted an orthogonal experiment with soymilk concentration, chitosan addition and brain temperature as the main influencing factors to explore the optimal preparation process of chitosan tofu. L 9 (3) 3 The design of the orthogonal test table is as follows:

[0117] .

[0118] Determine the optimal process conditions of chitosan tofu with the yield and sensory evaluation of tofu, the results are shown in the following table: .

[0119] It can be seen from the above table that the order of the influence of the three factors on the tofu yield and sensory quality is the amount of water-soluble chitosan added, the temperature of the squatting brain, and the squatting time of the brain. Considering the index of tofu yield, the optimization scheme is A2B2C3 (that is, the concentration of soybean milk 1:9, chitosan addition 0.6%, squatting temperature 85°C), the tofu yield of this combination is 151g / 100g; considering the sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com