Rice straw nutrition plug tray production line and method for preparing plug trays

A technology of rice straw and production line, which is applied in botany equipment and methods, culture medium, horticulture, etc., can solve the problems that rice straw seedling trays cannot be industrialized, and achieve maximum resource utilization, reduce pollution, and minimize investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

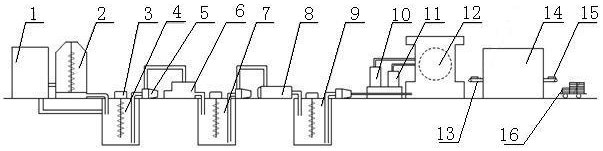

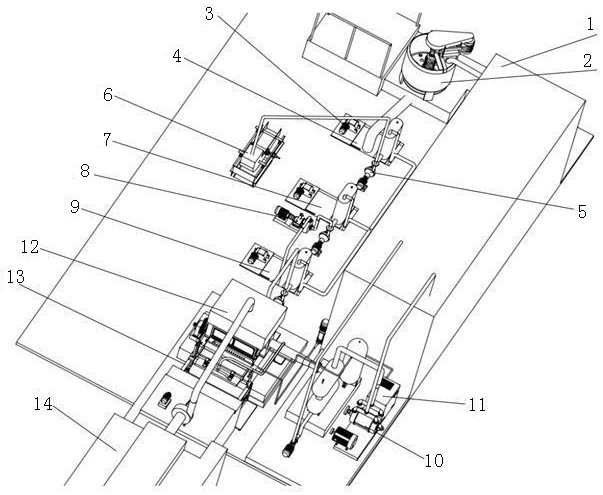

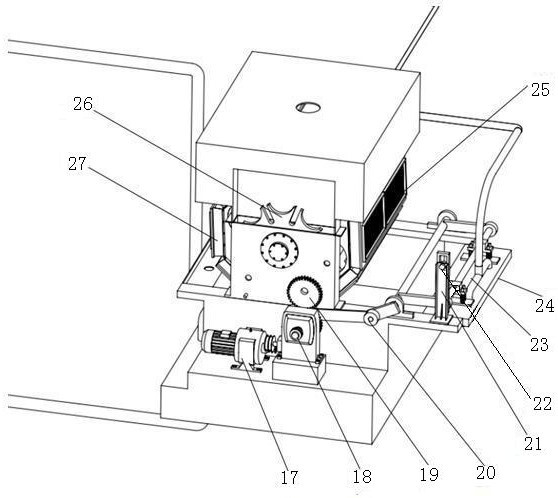

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

[0027] combine figure 1 , figure 2 As shown, this rice straw nutrition plug production line includes a reservoir 1, a beating machine 2, a screening machine 6, a micro refiner 8, a pneumatic rice straw nutrition plug forming machine 12, a drying furnace 14, and a water storage tank. 1. Beater 2. Screening machine 6. Micro-refiner 8. Pneumatic rice straw nutrition plug forming machine 12 is integrated on the skid-mounted platform. The screening machine 6, the micro-refiner 8, and the pneumatic rice straw nutrition plug forming machine 12 are all arranged on the side of the reservoir 1, and the skid-mounted platform is fixed on the ground. The upper covers of the material pool 7 and the No. 3 material storage pool 9 are all set on the skid-mounted platform. The space design is reasonable and the floor area is small, which is convenient to realize the automation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com