Liquid delivery pump

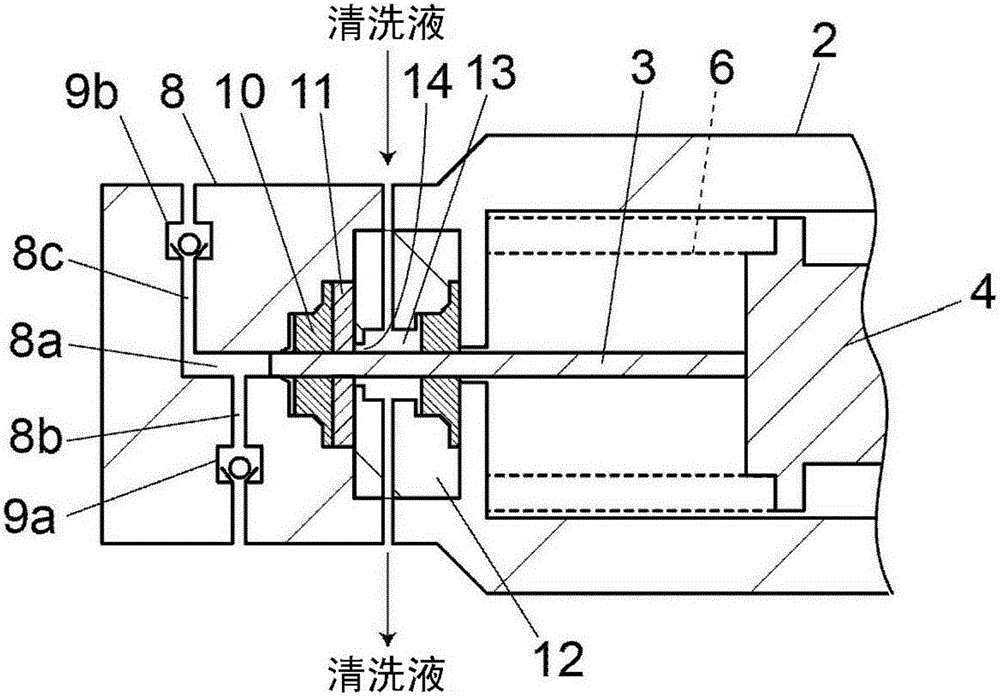

一种送液泵、液体的技术,应用在泵、活塞泵、泵元件等方向,能够解决柱塞损伤等问题,达到劣化抑制、抑制送液精度的下降、抑制摩耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

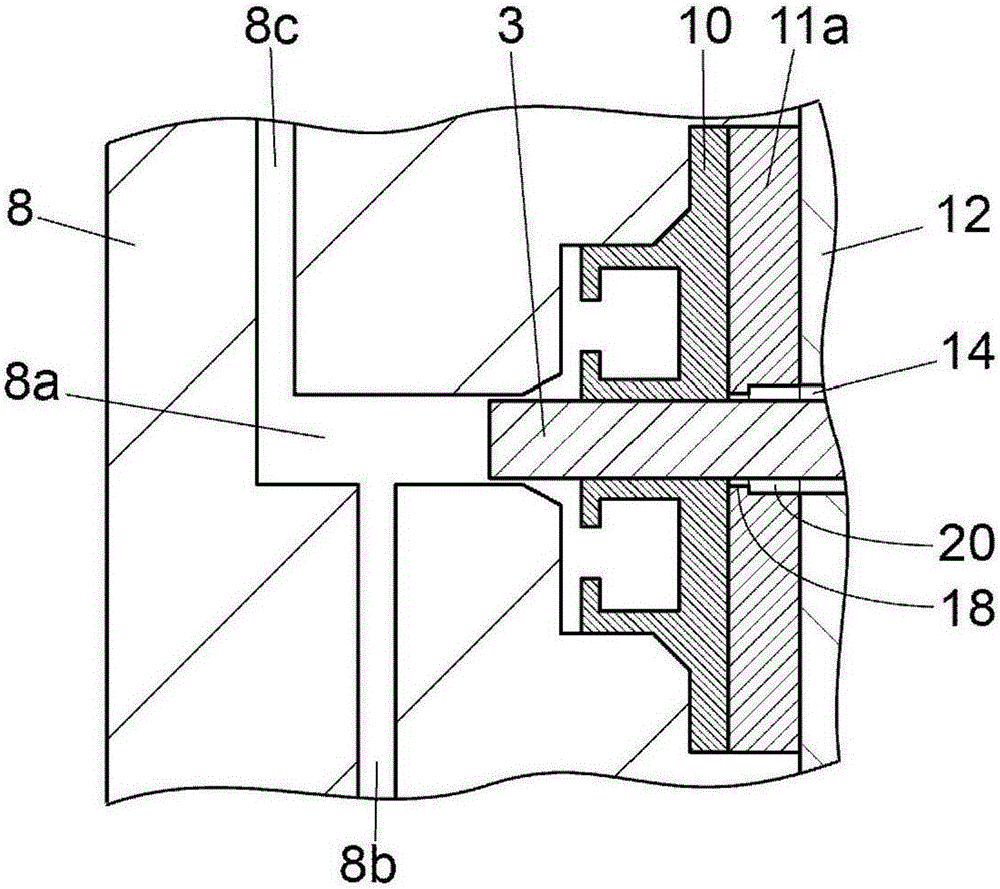

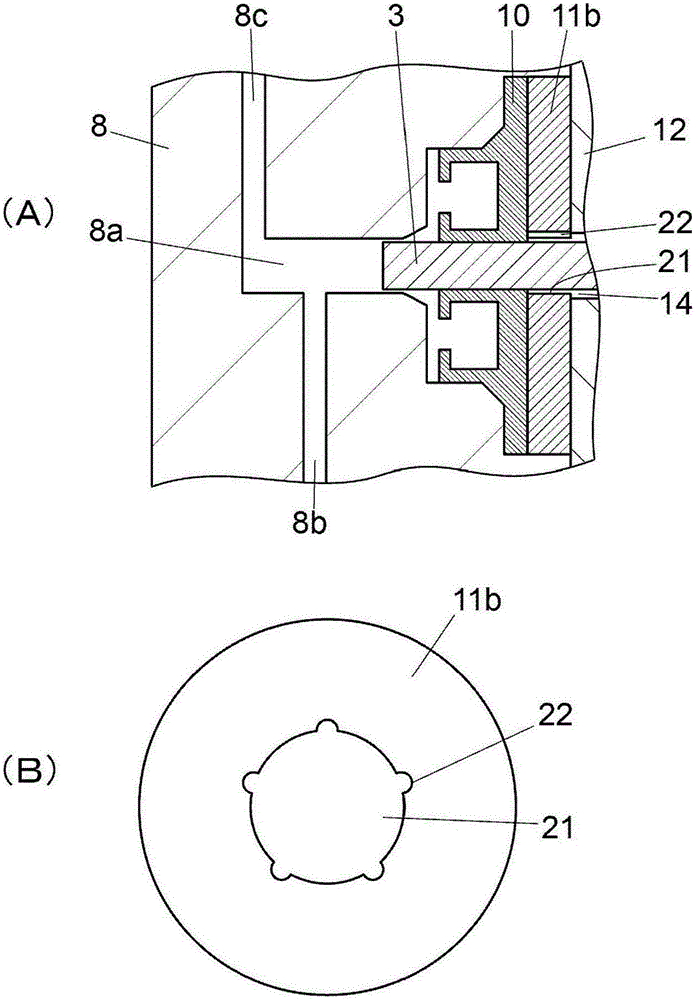

[0026] As a preferred embodiment of the liquid-sending pump of the present invention, it can be enumerated that in the center of the surface of the gasket on the side of the pump body, a concave portion that is as large as the plunger passage hole or larger than the plunger passage hole is provided as a liquid passage structure. The center of the recess is provided with a through hole structure. With this configuration, the cleaning liquid flowing out of the cleaning space is stored closer to the plunger seal, and the cleaning liquid is easily supplied to the plunger seal.

[0027] In addition, grooves for passing the cleaning liquid from the cleaning space may be provided on the inner peripheral surface of the through hole of the gasket as a liquid passing structure. With this configuration, it is possible to prevent the plunger seal from entering the through hole of the gasket and to supply the cleaning liquid to the plunger seal.

[0028] In addition, as a liquid passage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com