Methods of installing and implementing rigid pipes from vessels or floating supports

A technology of floating support and rigid pipe, which is applied in drilling pipe, casing, earthwork drilling and production, etc., and can solve problems such as inappropriate solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

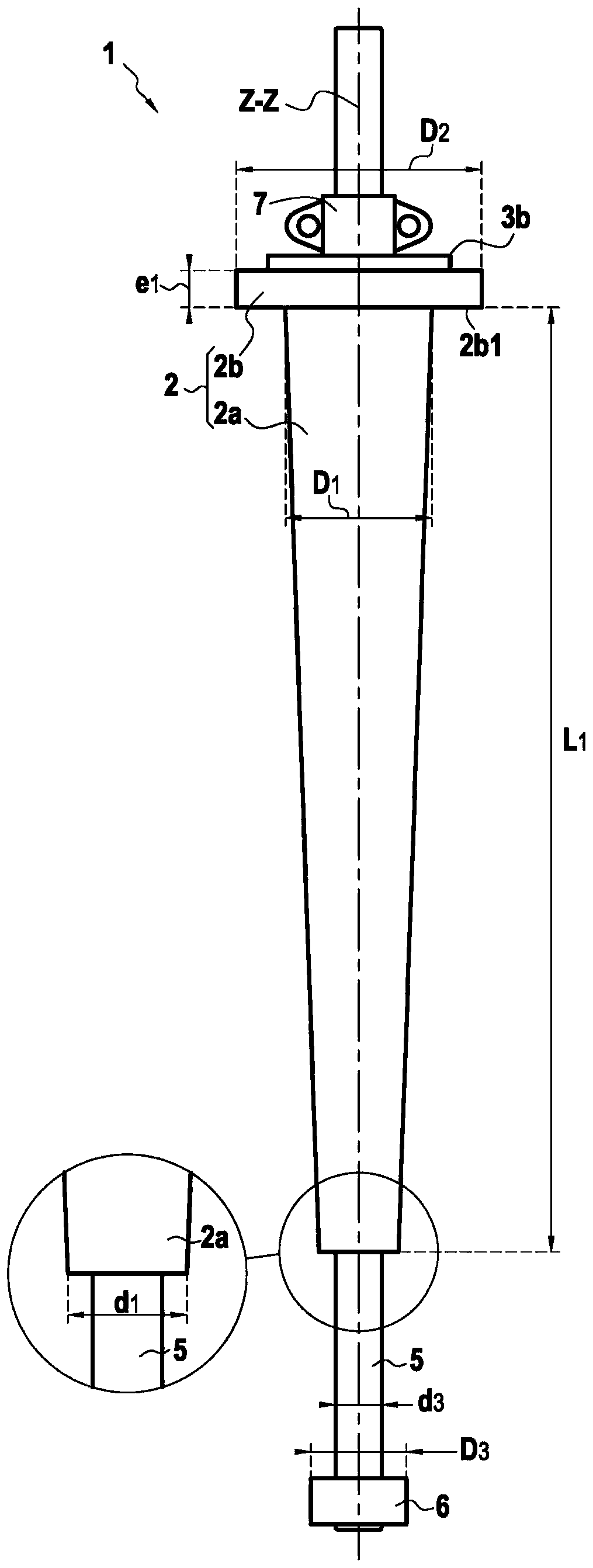

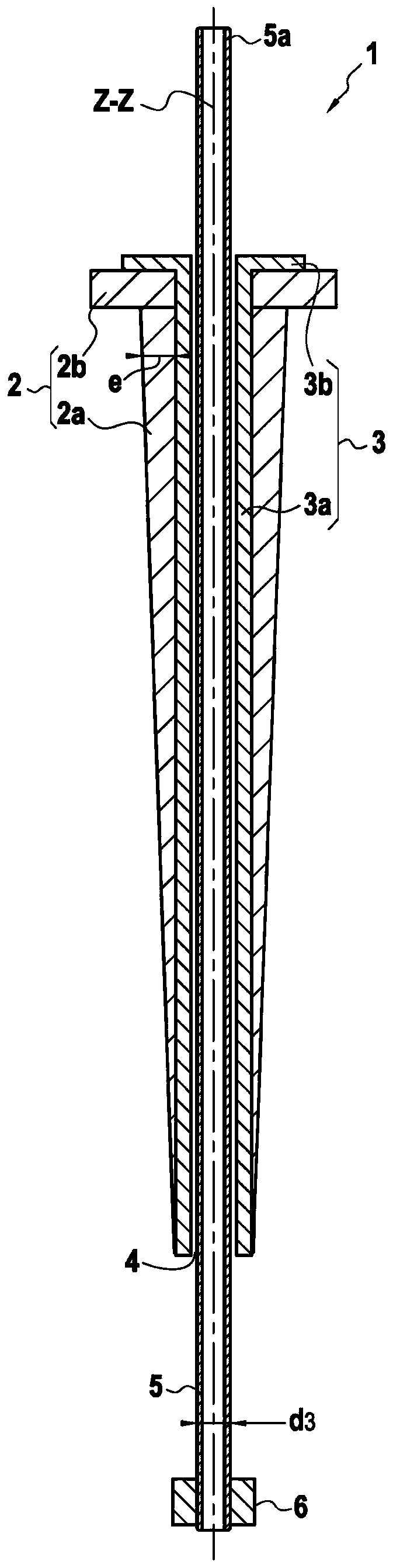

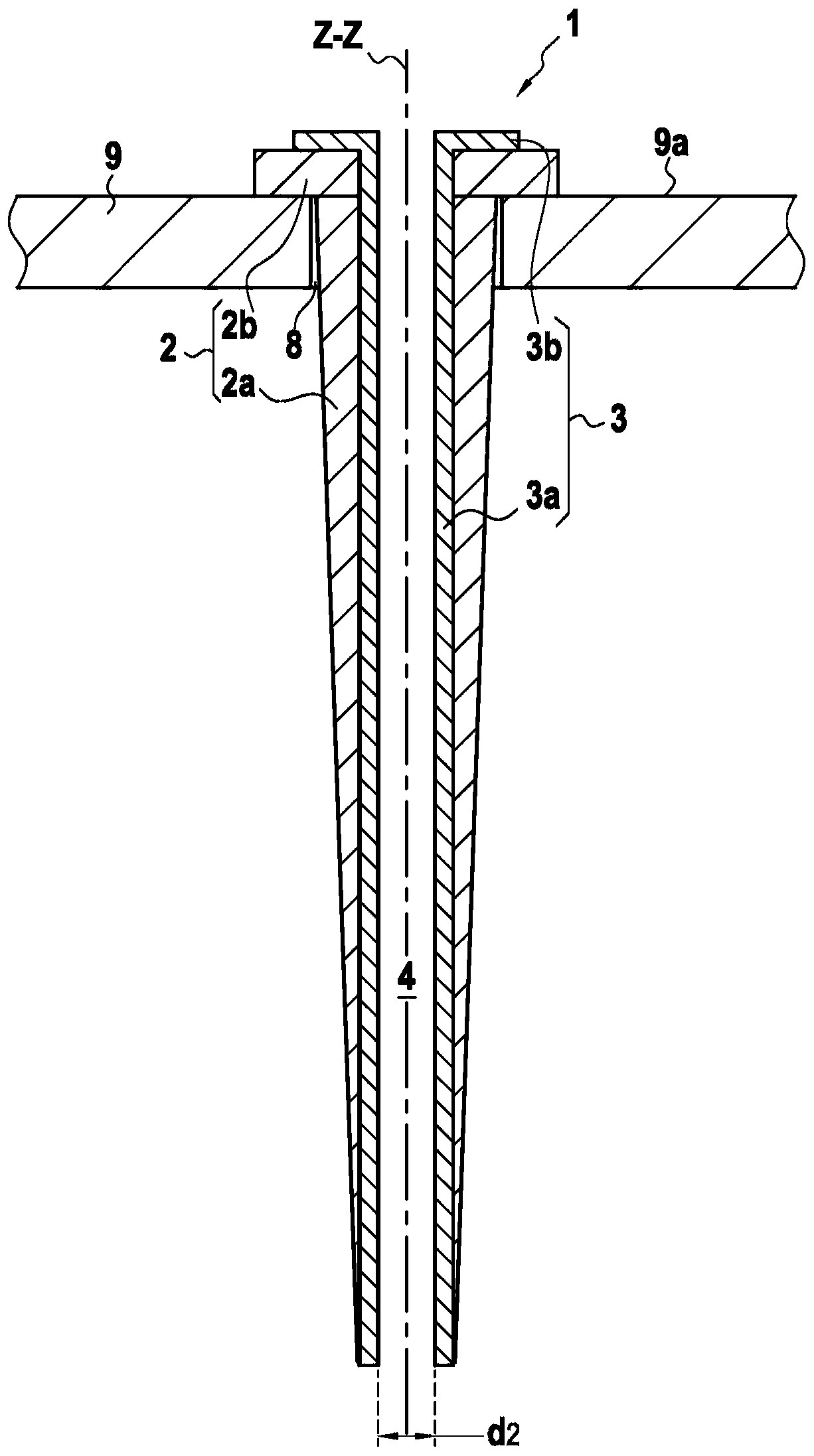

[0074] The sliding stiffener 1 shown in the attached drawings consists of a solid part made of a rigid solid material such as steel, possibly reinforced with glass fibers or synthetic fibers and consists of two parts: a conical main part 2a and a top fastening Plate 2b. The main part 2a of the bottom has an outer surface in the form of a frustoconical surface of revolution and extends a length L1. This main part is penetrated by said first cylindrical hole 4 having a circular axis on the same axis ZZ' as the axis of the frusto-conical outer surface and passing right through the main part. The diameter of the frustoconical outer surface of the main portion 2a varies between a maximum value D1 (at its top end) and a minimum value d1 (at its bottom end). In the figures, a conical part is shown with a rectilinear generator line (generator line) and a diameter that varies in a linear manner. In another embodiment, however, the generating line of the surface of revolution of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com