A test method for anti-pid performance of anti-reflection coating

A technology of anti-reflection film and test method, applied in the monitoring of photovoltaic systems, electrical components, photovoltaic modules, etc., can solve the problems of inability to rework, enterprise loss, scrap or downgrade, etc., to achieve simple and easy test costs, easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of test method of anti-reflection film anti-PID performance, comprises the steps:

[0028] (1) Take 4 groups of silicon wafers, respectively marked as sp1, sp2, sp3, and sp4, wherein sp1 and sp3 each have 20 pieces, and sp2 and sp4 each have 100 pieces, and are cleaned and textured according to the conventional battery manufacturing process. sp2 and sp4 conventional cell manufacturing process diffusion.

[0029] (2) After texturing / diffusion, sp1 and sp2 are simultaneously coated with anti-reflective coating according to the normal process of the production line; sp3 and sp4 are simultaneously coated with anti-PID coating process with anti-reflective coating. Sp1 and sp3 are sintered and annealed, and sp2 and sp4 are printed and sintered normally.

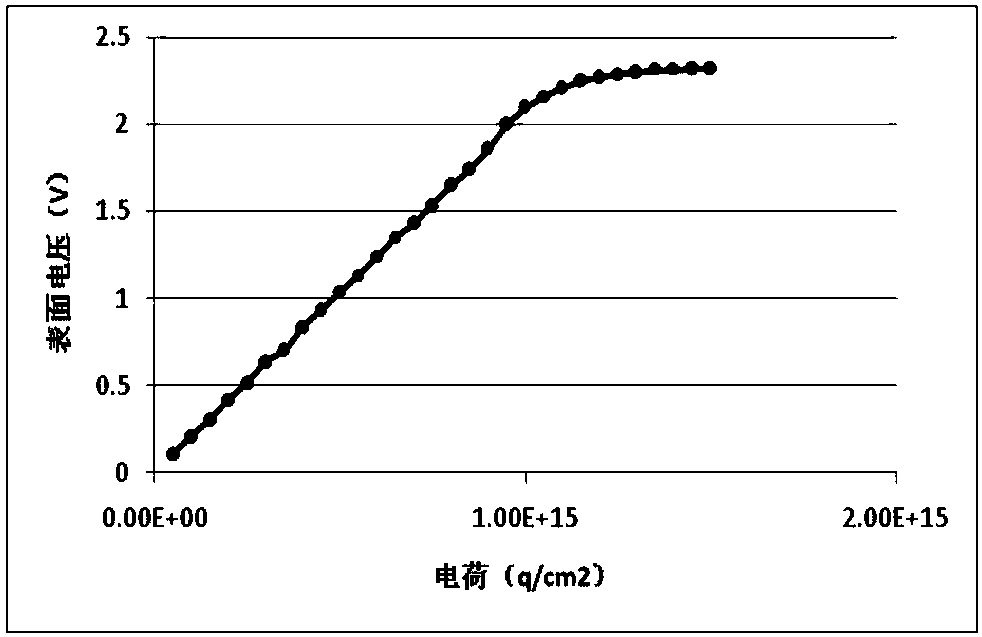

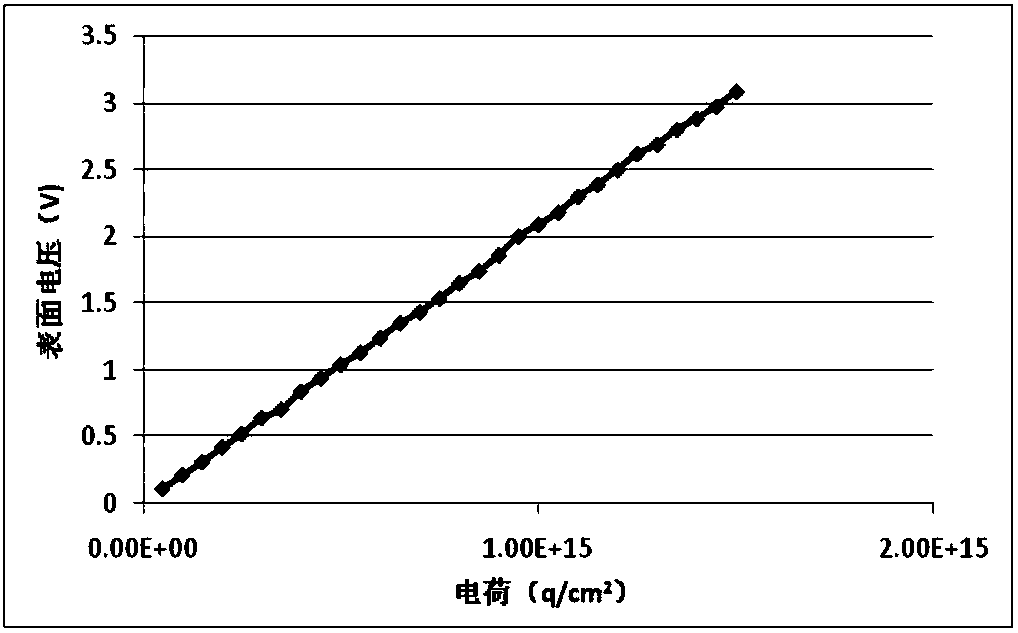

[0030] (3) Five silicon wafers were selected from each group of sp1 and sp3 silicon wafers to measure the anti-PID performance of the anti-reflection coating. The test results are figure 1 with figure 2 . from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com