Air-cooling heat dissipation structure of high-power modular power source

A technology of modular power supply and heat dissipation structure, applied in the direction of output power conversion device, modification of power electronics, cooling/ventilation/heating transformation, etc., can solve the service life discount of charging equipment, corrosion of circuit boards and sensitive components, dust Large and other problems, to achieve good heat dissipation effect, good protection effect, high protection level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

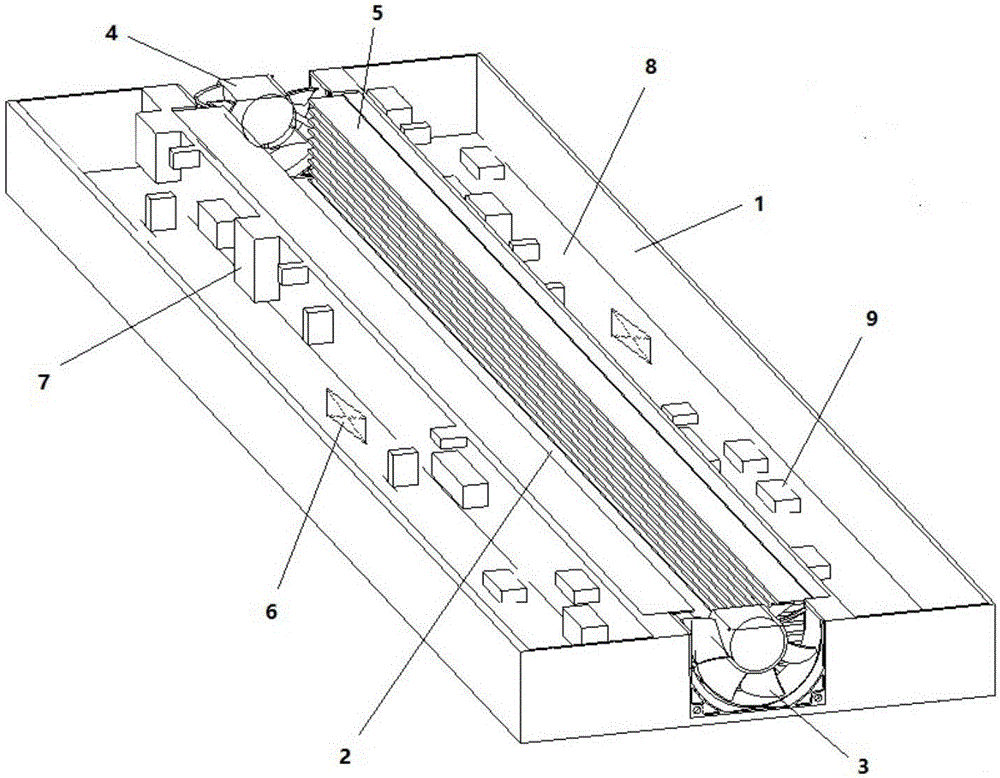

[0019] The object of the present invention is to provide an air-cooled heat dissipation structure and method for a high-power modular power supply, so as to overcome the above-mentioned defects in the prior art. The invention simultaneously solves the heat dissipation and protection problems of the high-power power supply, effectively improves the protection effect of the power supply module, and has the advantages of prolonging the service life of the power supply and being maintenance-free within the life cycle.

[0020] To achieve the above object, the present invention adopts the following technical solutions:

[0021] The inside of the power supply is isolated from the cooling air by sealing the electronic components of the whole machine, and the heat of the main internal heat-generating components is transferred to the cooling air duct through the heat-conducting material; Quickly go to the outside of the module through cold and heat exchange; achieve the purpose of over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com