Wave preventing method and breakwater system using wave preventing method

A wave breakwater and wave prevention technology, applied in the field of marine engineering safety, can solve the problems of difficulty in achieving wave elimination effect and low efficiency, and achieve the effect of good wave elimination effect and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

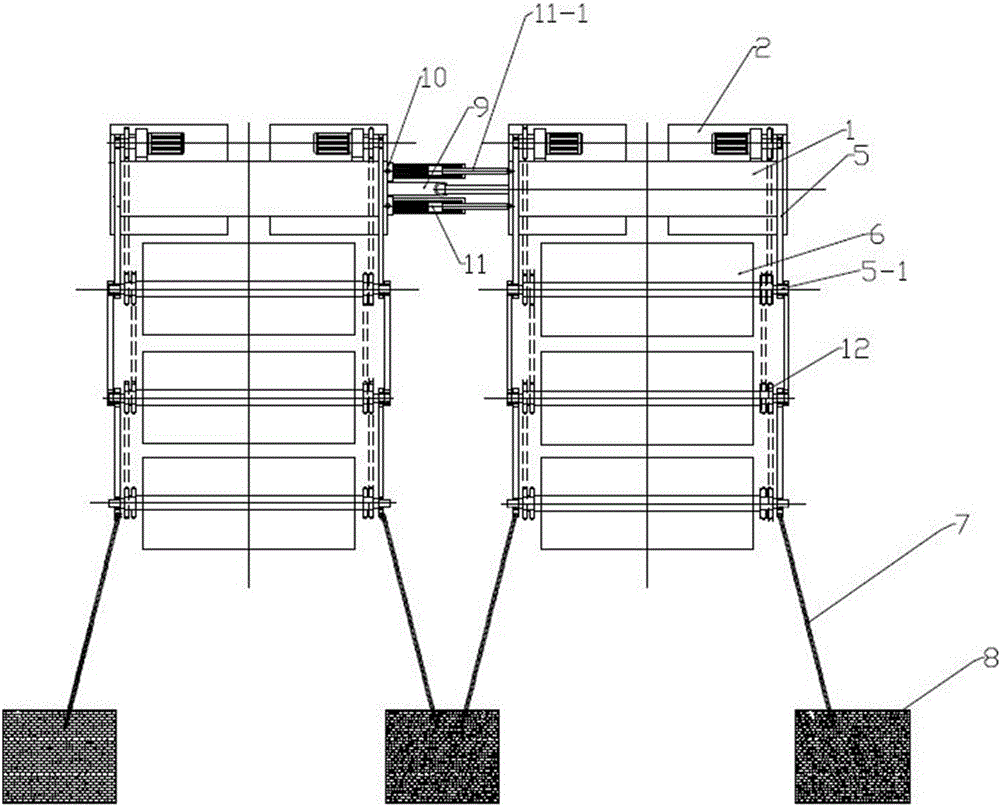

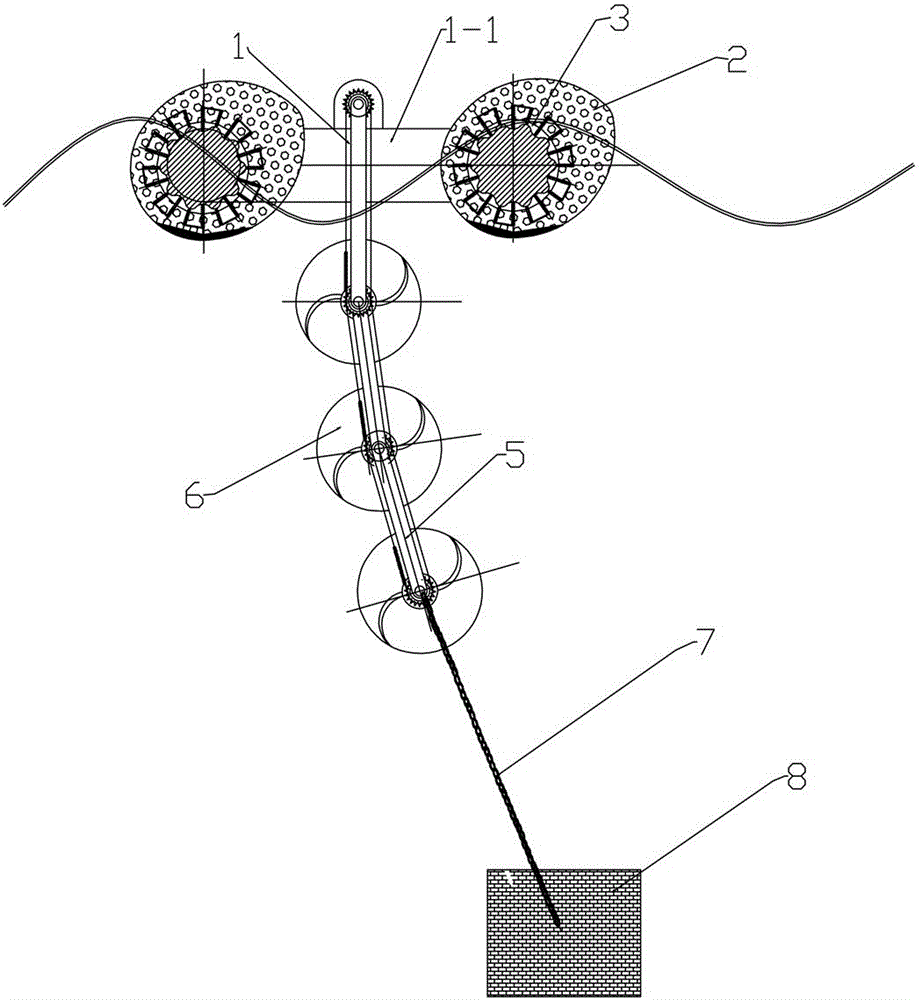

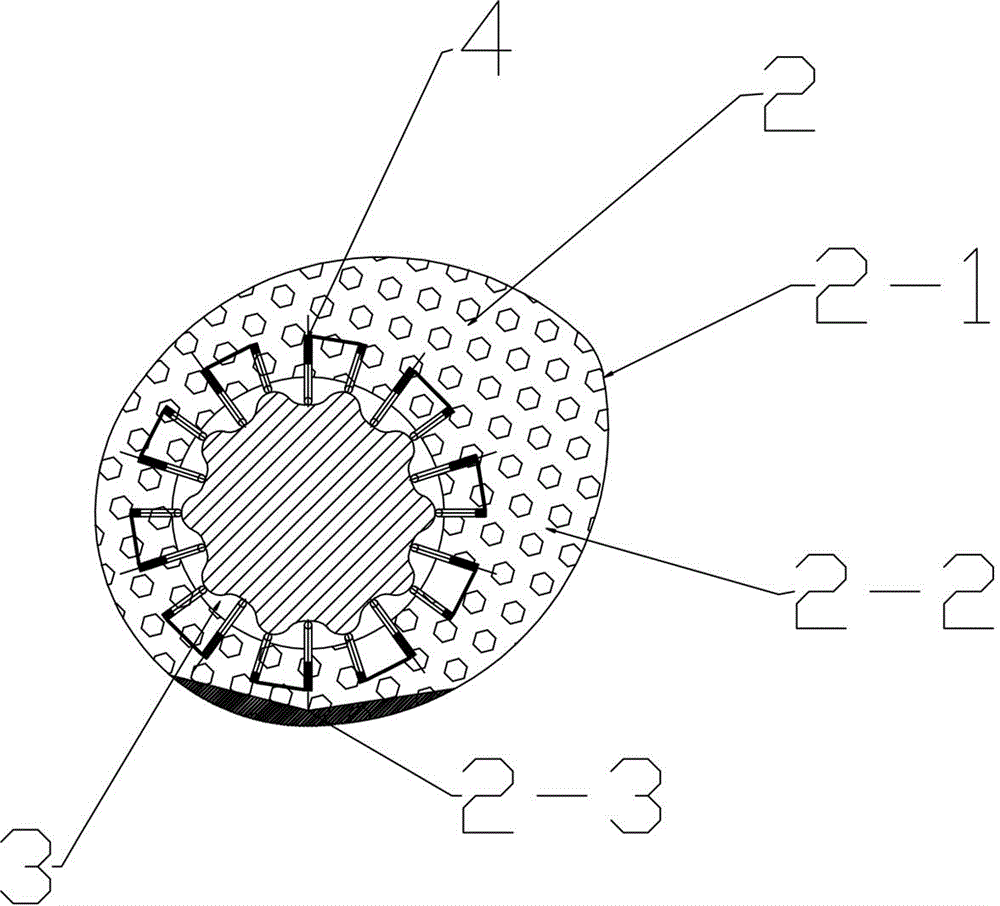

[0023] Such as figure 1 , 2 As shown in and 3, a kind of breakwater system provided by this embodiment includes at least two main buoyant bodies 1 and floats 2, the outside of which is a spherical fiberglass layer 2-1, and the inside of which is filled with glass beads 2-2, the bottom of the float 2 is fixed with a metal block 2-3, the float 2 is provided with a cylindrical float winding shaft 3, and the inner curved surface of the float winding shaft 3 is slidably connected with an annular two-way hydraulic damper device 4, the upper end of the annular two-way hydraulic damper 4 is fixedly connected with the float 2, the front and rear ends of the main floating body 1 are provided with a steering shaft 1-1 parallel to each other, and the ends of the steering shaft 1-1 are fixed with the float around the shaft 3 connection, the left and right sides of the main floating body 1 are fixed with at least two blade connecting rods 5 arranged in a straight line, each pair of adjacen...

Embodiment 2

[0026] A kind of breakwater system provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 4 , 5 and 6, but the two ends of the main floating body 1 and the blade 6 in the present embodiment are equipped with a sprocket 12, and the differential 5-2 is installed on the sprocket 12, and the sprocket 12 at the top end is in turn A speed increasing device 5-3 and a waterproof generator 5-4 are connected, and a drive chain 5-5 is connected between every pair of sprocket wheels 12 corresponding up and down.

[0027] The breakwater system provided in this embodiment can achieve the coordination of multiple blades 6 at different speeds to obtain the same speed output to the waterproof generator 5-4, so as to achieve the function of collecting and dissipating energy from waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com