Aluminum-doped SnO2 electro-catalytic positive pole, preparation method, and application thereof

A technology of tin dioxide and electrocatalysis, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of expensive, secondary pollution of water bodies, low oxidation efficiency, etc. Achieve the effect of low cost, high catalytic activity and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

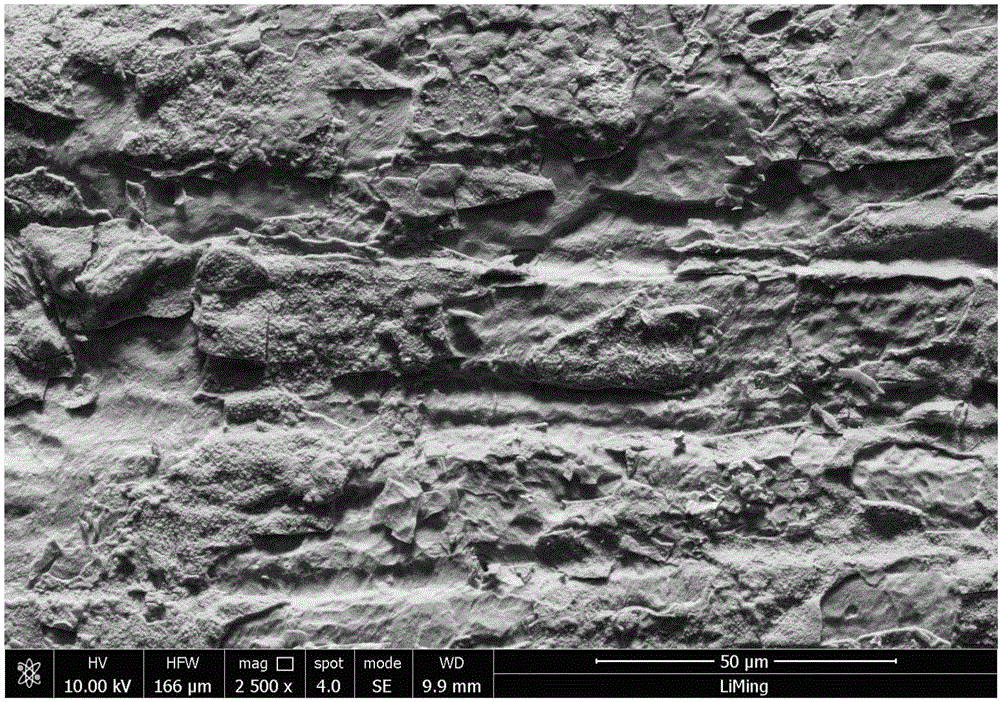

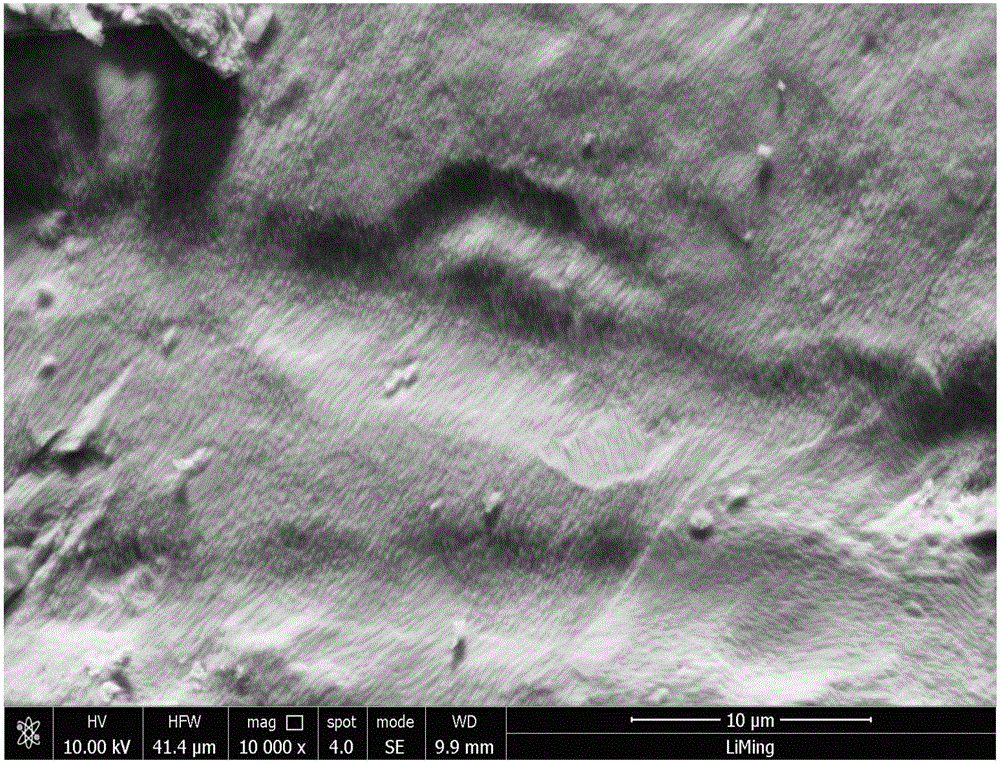

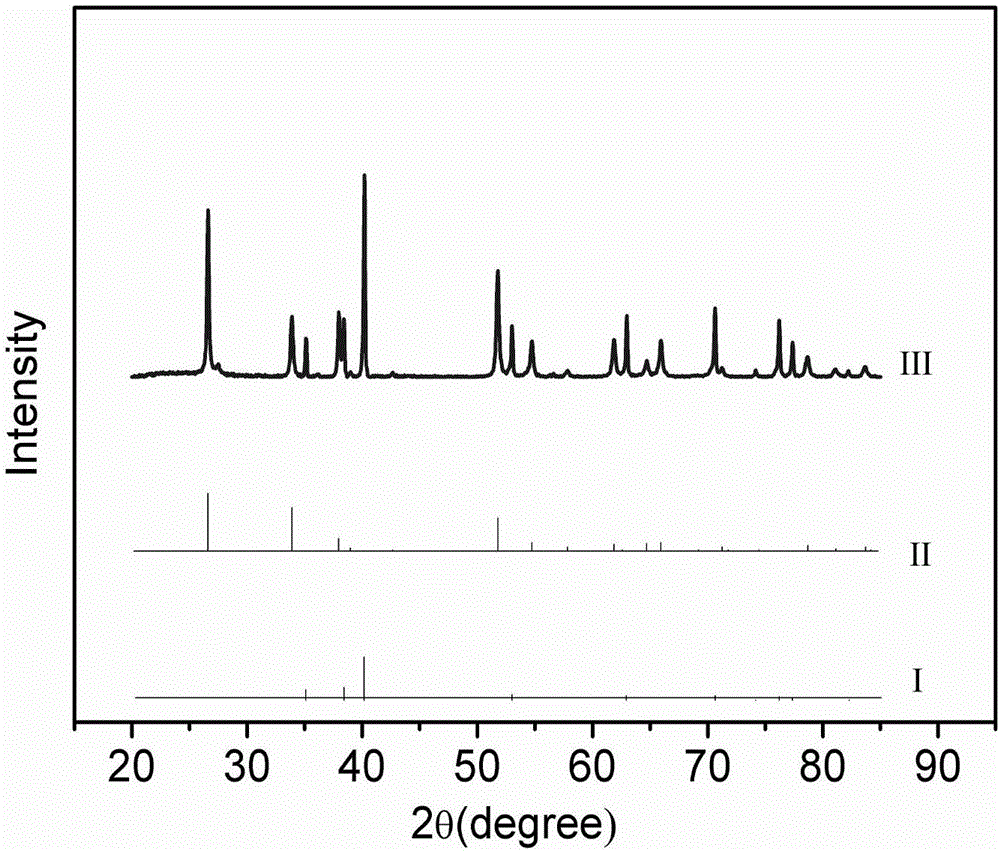

[0029] An aluminum-doped tin dioxide electrocatalytic anode is composed of a titanium substrate and an anode paint coated on the titanium substrate, and the anode paint is made of the following components in molar fractions: 600 parts of citric acid, ethyl 100 parts of diol, 100 parts of tin tetrachloride, 5 parts of antimony trichloride, and 1 part of aluminum trichloride.

[0030] Concrete preparation steps are as follows:

[0031] Step 1, polishing the titanium substrate until the surface has a metallic luster, rinsing it with distilled water, and placing it in a water bath of 40% sodium hydroxide solution at 80°C for 2 hours to obtain an alkali-treated titanium substrate;

[0032] Step 2, taking out the alkali-treated titanium substrate and rinsing it with distilled water, placing the alkali-treated titanium substrate in a 10% oxalic acid solution for 2 hours at 70-100° C. to obtain an acid-treated titanium substrate;

[0033] Step 3, weigh each component according to the...

Embodiment 2

[0040] An aluminum-doped tin dioxide electrocatalytic anode is composed of a titanium substrate and an anode coating coated on the titanium substrate, and the anode coating is made of the following components in molar fractions: 650 parts of citric acid, ethyl 200 parts of diol, 150 parts of tin tetrachloride, 6.5 parts of antimony trichloride, and 2 parts of aluminum trichloride.

[0041] Concrete preparation steps are as follows:

[0042] Step 1, polishing the titanium substrate until the surface has a metallic luster, rinsing it with distilled water, and placing it in a water bath of 40% sodium hydroxide solution at 80°C for 2 hours to obtain an alkali-treated titanium substrate;

[0043] Step 2, taking out the alkali-treated titanium substrate and rinsing it with distilled water, placing the alkali-treated titanium substrate in a 10% oxalic acid solution for 2 hours at 70-100° C. to obtain an acid-treated titanium substrate;

[0044] Step 3, weigh each component according...

Embodiment 3

[0051] An aluminum-doped tin dioxide electrocatalytic anode is composed of a titanium substrate and an anode coating coated on the titanium substrate, and the anode coating is made of the following components in molar fractions: 700 parts of citric acid, ethyl 300 parts of diol, 200 parts of tin tetrachloride, 10 parts of antimony trichloride, and 3 parts of aluminum trichloride.

[0052] Concrete preparation steps are as follows:

[0053] Step 1, polishing the titanium substrate until the surface has a metallic luster, rinsing it with distilled water, and placing it in a water bath of 40% sodium hydroxide solution at 80°C for 2 hours to obtain an alkali-treated titanium substrate;

[0054] Step 2, taking out the alkali-treated titanium substrate and rinsing it with distilled water, placing the alkali-treated titanium substrate in a 10% oxalic acid solution for 2 hours at 70-100° C. to obtain an acid-treated titanium substrate;

[0055] Step 3, weigh each component according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com