Unmanned helicopter carbon fiber undercarriage apparatus

An unmanned helicopter, carbon fiber technology, applied in landing gear, aircraft parts, transportation and packaging, etc., to achieve the effect of protecting safety, increasing flight mileage, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

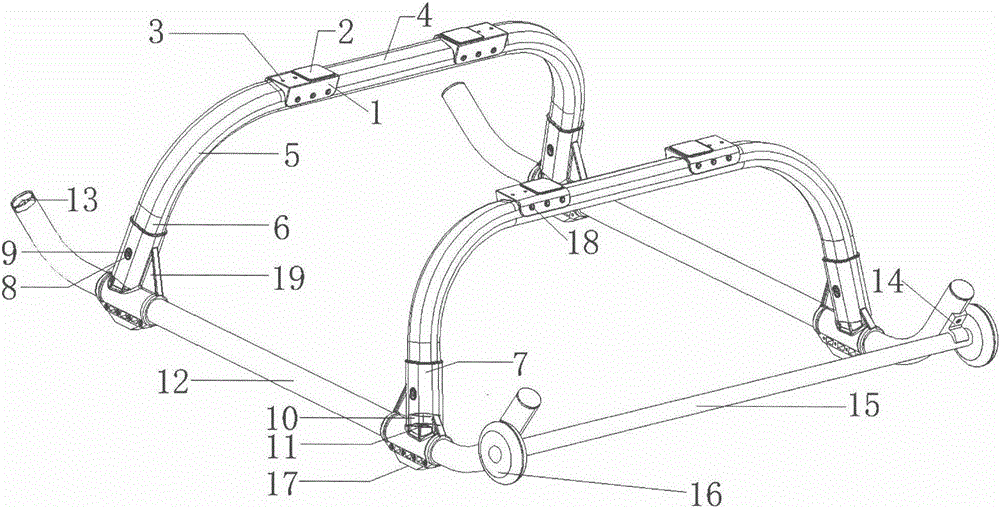

[0014] Refer to attached figure 1 A carbon fiber landing gear device for an unmanned helicopter, comprising a base of the unmanned helicopter and a carbon fiber installation platform 1, a buffer pad A2, a carbon fiber beam 4 is connected and fixed by a standard part through the installation hole 3, and the upper plane of the carbon fiber installation platform 1 has a buffer pad A2 The fixed concave frame and the installation hole 3, the three-week fixed part of the carbon fiber installation platform 1 and the shape of the carbon fiber beam 4 are closely matched in three axes. After fixing with epoxy resin, use stainless steel rivets 18 on the sides for assembly.

[0015] The carbon fiber crossbeam 4, carbon fiber crossbeam R5, and carbon fiber support column 6 are integral carbon fiber rectangular tubes 20, and the four corners of the carbon fiber rectangular tube 20 have R transitions. , aramid fiber, and epoxy resin are integrally formed through tooling mold 22 composite pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com