Wide shallow-draft ship

A kind of ship, wide technology, applied in the field of hull structure, can solve the problem of the propeller flow is not too smooth, damage, rapidity, general maneuverability and turning performance, etc., to reduce the width of the waterplane, improve the resistance performance, and economic benefits. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

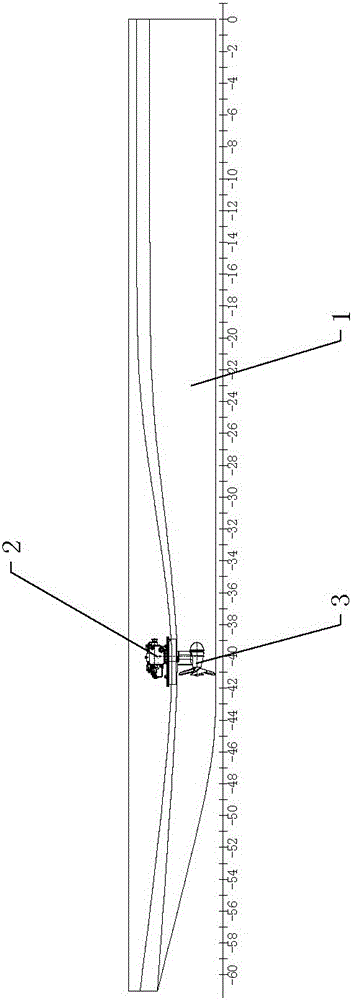

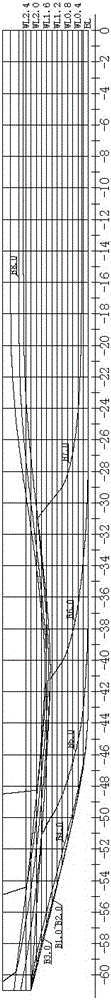

[0043] One of the embodiments of a wide and shallow draft ship of the present invention, such as Figure 1 to Figure 6 means, such as image 3 As shown in , the hull structure with flat bottom and round bilge is set, such as Figure 4 , and the side structure is set in the form of a floating side structure, which refers to the oblique extension of the side structure above the design waterline, and the knuckle line of the side structure forms at least one sinking concave part from the bow to the stern . In the longitudinal direction, it gradually transitions to the round bilge towards the bow section and the stern section.

[0044] The ship adopts the streamlined design of the round bilge, and adopts the form of side structure floating above the load waterline. On the basis of fully ensuring the deck space, the width of the hull 1 at the waterline is reduced, and the resistance performance of the hull 1 is improved. And it adopts a wide and gentle bottom rise structure, whic...

Embodiment 2

[0048] One of the embodiments of a ship with wide and shallow draft of the present invention, such as Figure 1 to Figure 6 As shown, features that are not explained in Embodiment 2 are explained in Embodiment 1, and will not be repeated here.

[0049] Such as Figure 1 ~ Figure 4 As shown, the line shape of the main hull of an 83-meter beach-washing car-passenger ferry is provided. The line shape of the ship is dominated by longitudinal flow, and the line shape of the ship is arranged symmetrically from the bow to the stern, and only the middle and rear part of the main hull is shown in the figure.

[0050] The owner's dimensions are:

[0051] Total length: 83 meters,

[0052]Main hull length: 73.2 meters,

[0053] Molded width: 17.4 meters,

[0054] Molded depth: 3.3 meters,

[0055] Full load draft: 2.0 meters,

[0056] Empty draft: 1.5 meters,

[0057] In this embodiment, the chamfer line is configured as a chamfer line with two sunken recesses.

[0058] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com