Process of making chili sauce

A production process, the technology of chili sauce, applied in the field of food processing, can solve the problems of easy to get angry, short shelf life, long production time, etc., and achieve the effect of not easy to get angry, smooth taste, rich in vitamins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the embodiment of the present invention, a kind of preparation technology of chilli sauce comprises the following steps:

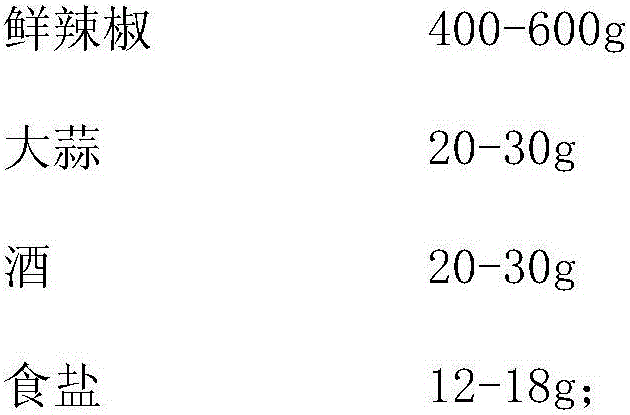

[0025] (1) Prepare raw materials: select local fresh peppers and garlic in Guangnan; remove the stalks of fresh peppers, wash and dry the epidermis, and set aside; after peeling the garlic, wash and dry the epidermis, and set aside; take the dried fresh Pepper, garlic, and wine and salt, according to the following mass ratio:

[0026]

[0027] Among them, the wine is 55% fragrance-type grain-wrapped wine;

[0028] (2) Primary processing: mix and crush fresh chili and garlic to 5mm sized particles, cool to room temperature, add half a measure of salt and half a measure of wine, stir evenly, cool to 8°C-12°C, and wait for secondary processing;

[0029] (3) Secondary processing: crush the primary processed materials in step (2) to gel again, cool to room temperature, add the remaining salt and wine and stir evenly, after cooling, put them into t...

Embodiment 2

[0036] In the embodiment of the present invention, a kind of preparation technology of chilli sauce comprises the following steps:

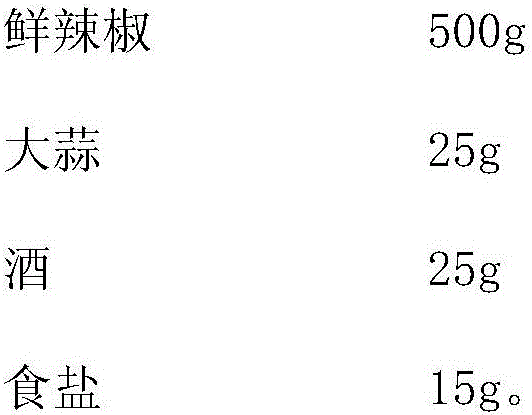

[0037] (1) Prepare raw materials: select local fresh peppers and garlic in Guangnan; remove the stalks of fresh peppers, wash and dry the epidermis, and set aside; after peeling the garlic, wash and dry the epidermis, and set aside; take the dried fresh Pepper, garlic, and wine and salt, according to the following mass ratio:

[0038]

[0039] Among them, the wine is 55% fragrance-type grain-wrapped wine;

[0040] (2) Primary processing: mix and crush fresh chili and garlic to 5mm sized particles, cool to room temperature, add half a measure of salt and half a measure of wine, stir evenly, cool to 8°C-12°C, and wait for secondary processing;

[0041] (3) Secondary processing: crush the primary processed materials in step (2) to gel again, cool to room temperature, add the remaining salt and wine and stir evenly, after cooling, put them into t...

Embodiment 3

[0048] In the embodiment of the present invention, a kind of preparation technology of chilli sauce comprises the following steps:

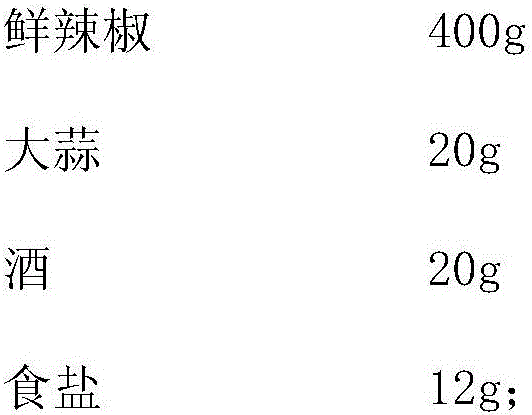

[0049] (1) Prepare raw materials: select local fresh peppers and garlic in Guangnan; remove the stalks of fresh peppers, wash and dry the epidermis, and set aside; after peeling the garlic, wash and dry the epidermis, and set aside; take the dried fresh Pepper, garlic, and wine and salt, according to the following mass ratio:

[0050]

[0051]

[0052] Among them, the wine is 55% fragrance-type grain-wrapped wine;

[0053] (2) Primary processing: mix fresh chili and garlic, crush them into 5mm sized particles, cool to room temperature, add half a measure of salt and half a measure of wine, stir evenly, cool to 10°C, and wait for secondary processing;

[0054] (3) Secondary processing: crush the primary processed materials in step (2) to gel again, cool to room temperature, add the remaining salt and wine and stir evenly, after cooling, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com