Seat type longitudinal bobbin winder

A technology of longitudinal winding and bobbin, applied in the direction of transmission device, gear transmission device, fishing reel, etc. Convenience and other issues, to achieve the effect of not being easy to twist, ensuring flexibility and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

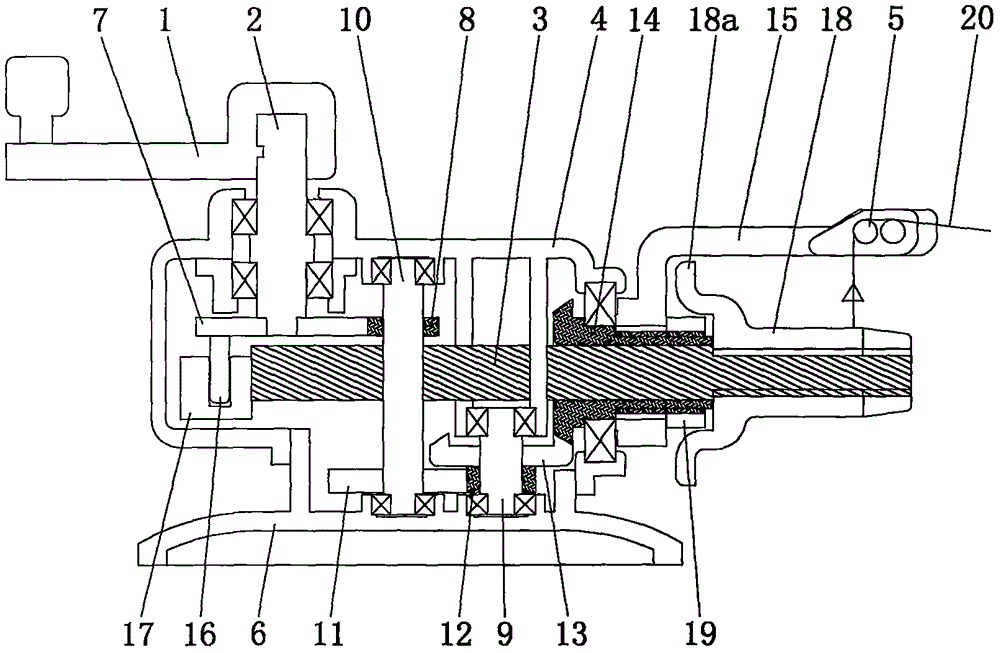

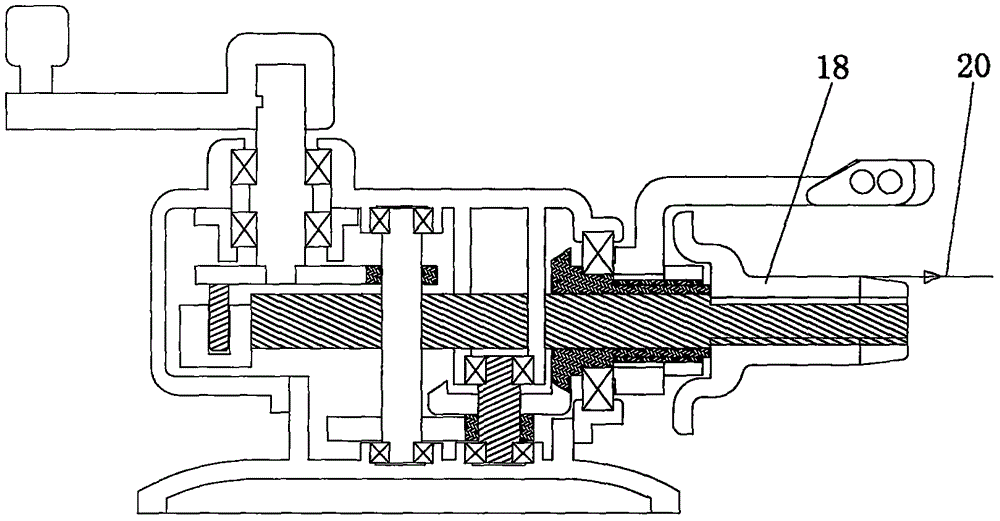

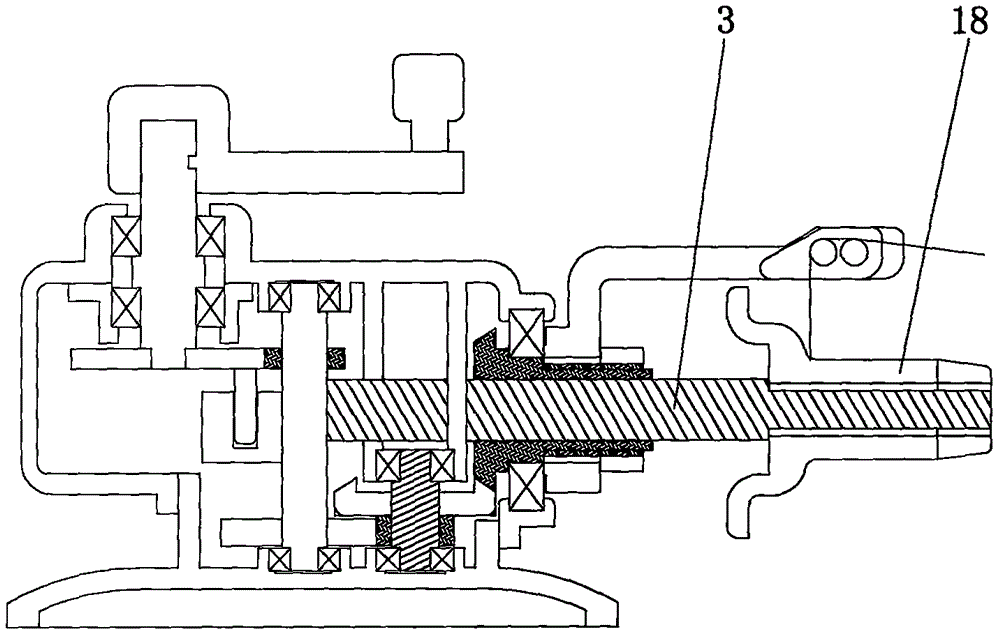

[0024] like figure 1 , figure 2 , image 3 As shown, the shell 4 is preferably formed by buckling two halves, and a base 6 is provided on one side of the shell 4 , and the base 6 is inserted and fixed with the shell 4 . A rocker arm 1 is arranged on the other side of the housing 4, and the rocker arm 1 is fixedly connected to the outer end of the rocker arm shaft 2, and the rocker arm shaft 2 is supported by the housing 4 through a bearing. The inner end of the rocker shaft 2 extends into the casing 4, and an input gear 7 is installed on the inner end of the rocker shaft 2. The input gear 7 meshes with the first-stage pinion 8, and the first-stage pinion 8 is set on the first intermediate shaft One end of the first intermediate shaft 10, the two ends of the first intermediate shaft 10 are respectively supported by bearings, the housing 4 and the base 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com