Transmission device having a hydraulic system

A technology of hydraulic system and transmission, applied in the direction of transmission, geared components, transmission control, etc., to achieve the effect of reducing hydraulic power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

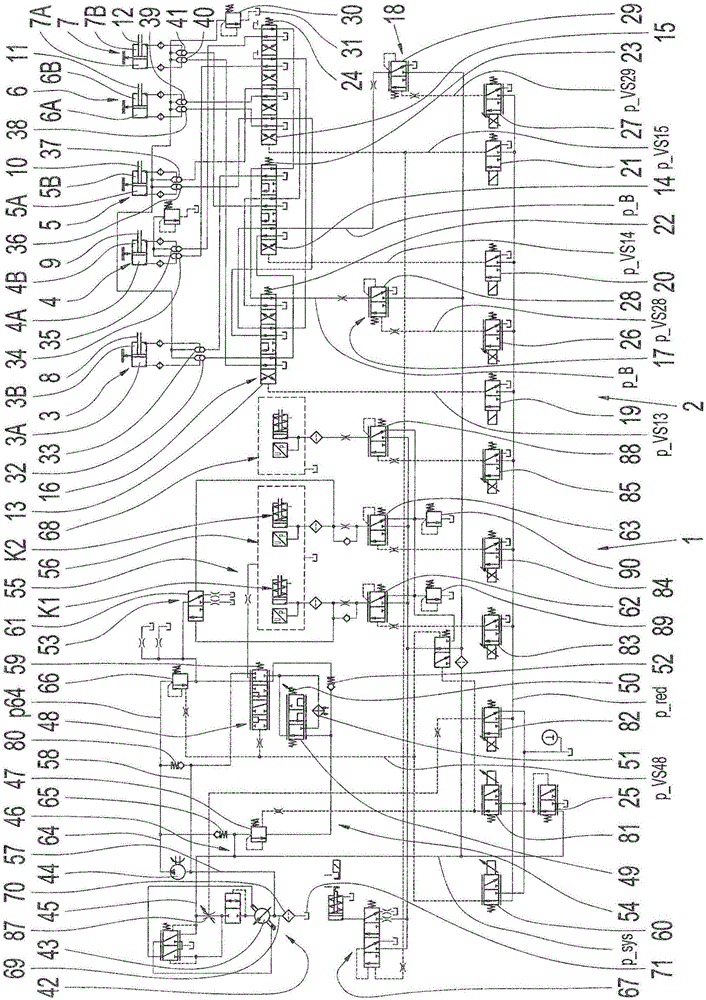

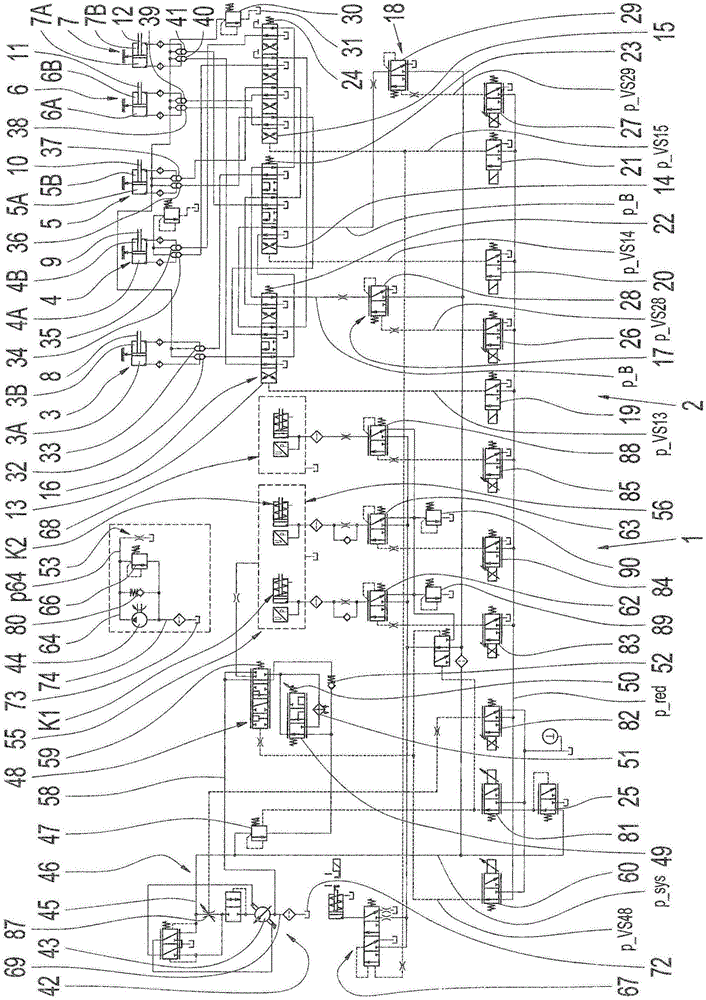

[0048] figure 1 Shows a hydraulic diagram of the transmission device 2 or the hydraulic system 1 of the transmission, or the hydraulic actuation system, currently embodied as a dual clutch transmission, in which nine transmission ratios for forward travel and one transmission ratio for reverse travel can be engaged . These transmission ratios can be switched on and off via five shifting elements 8 - 12 which can be adjusted by hydraulically actuatable piston-cylinder arrangements 3 - 7 . The switching element is presently designed as a switching lever. The actuating pressure p_B can be applied in the area of the piston-cylinder arrangement 3-7 or in the area of the piston chamber 3A, 3B or 4A, 4B or 5A, 5B or 6A, 6B or 7A, 7B via the valve device 16, which valve The device 16 now comprises three pilot-controlled switching valves 13 - 15 coupled to one another via lines. The switching valves 13 - 15 each have a plurality of switching positions for forming the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com