Method and device for continuously suppling a precursor

A technology of precursors and equipment, applied in separation methods, chemical instruments and methods, evaporator regulation/control, etc., can solve problems such as complex coating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

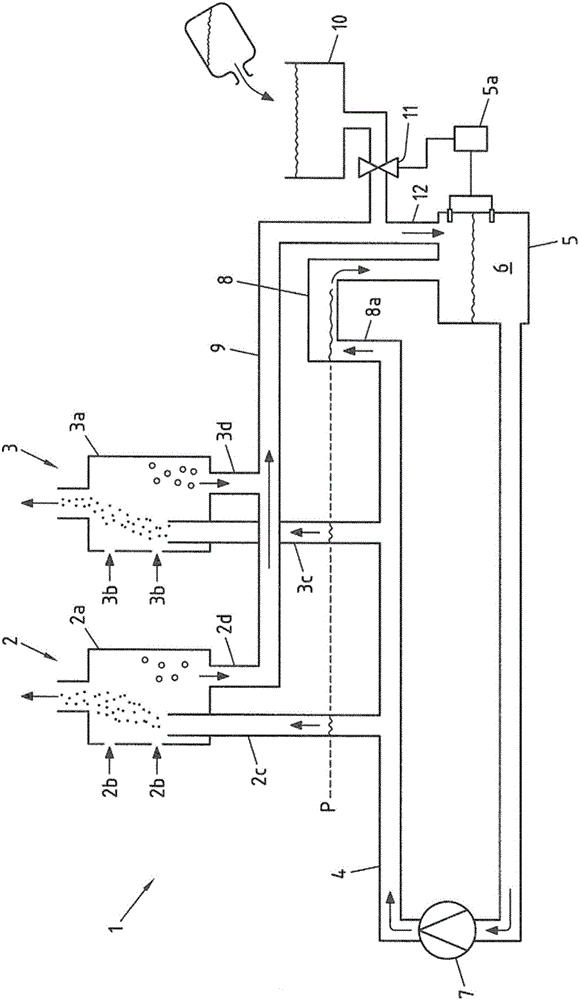

[0025] figure 1 First, a first exemplary embodiment of a device 1 for continuous precursor supply according to the invention is shown schematically. The plant 1, as part of a coating plant, in particular a plasma coating plant, has a plurality of extraction devices 2, 3 for supplying metal strips or individual goods (not shown here) The coating module of the coating is not shown here. In the extraction devices 2, 3 of the coating module (not shown here), the precursor 6 is withdrawn, for example atomized, from the inlet lines 2c, 3c of the respective extraction device by the inflow of the process gas 2b, 3b and fed (not shown) out of the coating module. In the inlet pipes 2 c , 3 c , which are at least partially configured as risers, the precursor level P is decisive for the amount of precursor removed by the extraction devices 2 , 3 as a function of the parameters of the process gas 2 b , 3 b. Consequently, the precursor level P in the feed lines 2c, 3c is kept as constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com