Vibration motor

A technology of vibrating motors and vibrating components, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of weak overall rigidity of vibrating components, complicated production processes, high production costs, etc., to avoid noise and defective products, improve yield, and reduce deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

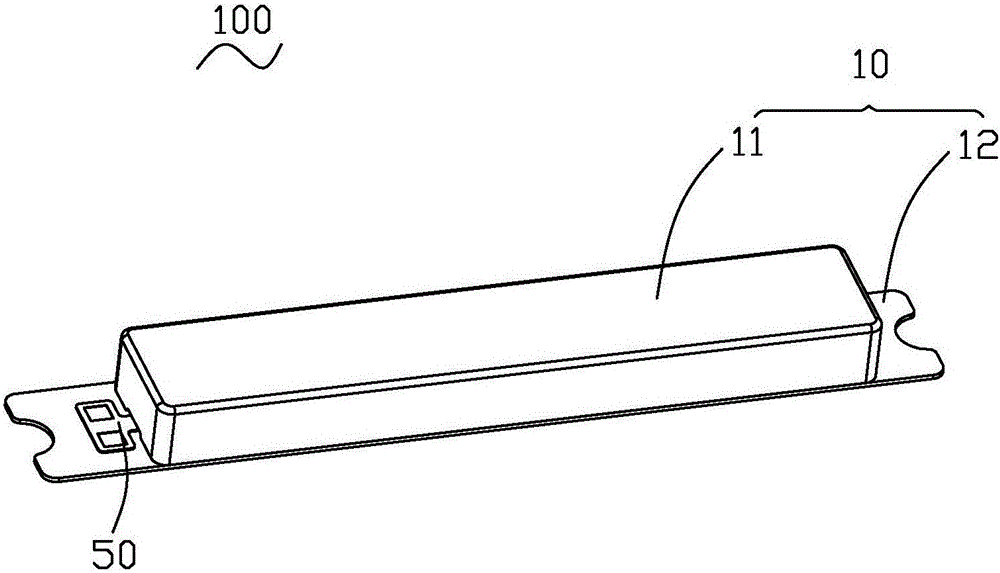

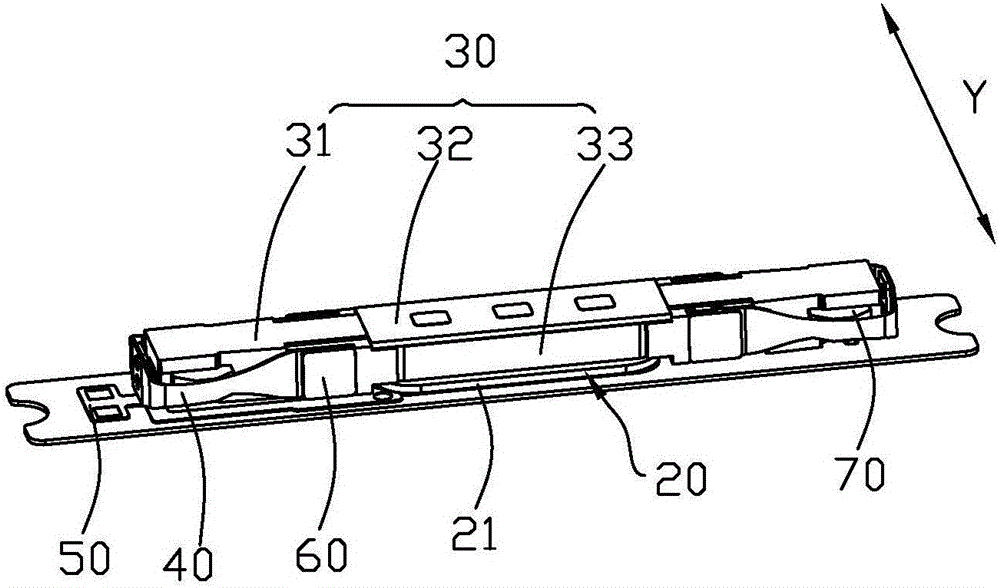

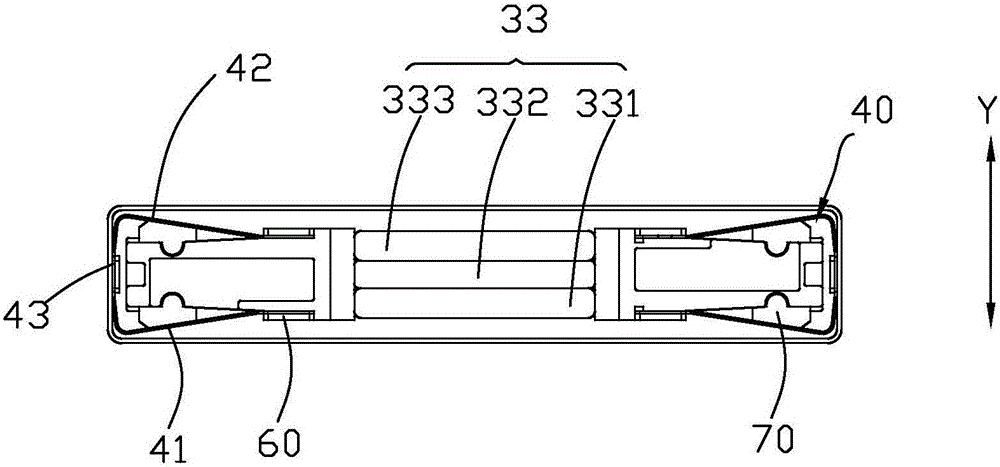

[0022] Figure 1-3 A vibration motor 100 in one embodiment of the present invention is shown. Such as Figure 1-3 As shown, the vibrating motor 100 generally includes a casing 10 with a receiving space (not labeled), and a fixing component 20 , a vibrating component 30 and an elastic connecting member 40 accommodated in the casing 10 . Wherein, the housing 10 includes a housing 11 and a cover plate 12 covering the housing 11 to cooperate with the housing 11 to form a receiving space. The fixing assembly 20 is fixed on the cover plate 12 . The vibrating assembly 30 is suspended in the accommodating space through the elastic connecting piece 40, and along the direction perpendicular to the length direction of the cover plate 12 (see Figure 2-3 In the Y direction) reciprocating vibration. The direction Y is the vibration direction.

[0023] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com