Battery pack cooling method and system

A cooling method and technology of a cooling system, applied in the field of cooling methods and systems of battery packs, can solve the problems of energy waste, high energy consumption, and shorten the service life of batteries, and achieve the advantages of avoiding energy waste, high flexibility, and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

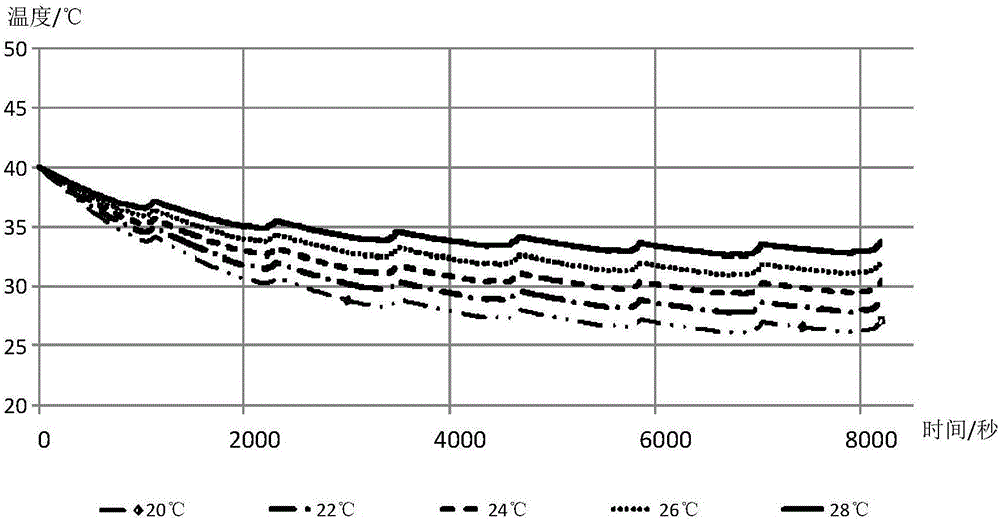

[0059] figure 1 A schematic flow chart of the cooling method for the battery pack provided by the embodiment of the present invention, as figure 1 As shown, the cooling method of the battery pack in this embodiment may specifically include the following steps:

[0060] 101. Detect the temperature of the battery pack.

[0061] Normally, the battery pack has an optimal temperature range. When the temperature of the battery pack is in the optimal temperature range, the working efficiency is the highest, and it is beneficial to prolong the service life of the battery pack. When the temperature of the battery pack is not in the optimal temperature range , such as in a high temperature environment, the heat generated by the battery pack will dissipate slowly, which will affect the performance of the battery. Therefore, in order to reduce the temperature of the battery pack beyond the optimal temperature range and improve the cooling efficiency, Water cooling will be used to cool d...

Embodiment 2

[0083] Figure 4 Another schematic flow chart of the battery pack cooling method provided by the embodiment of the present invention, such as Figure 4 As shown, the cooling method of the battery pack in this embodiment may specifically include the following steps:

[0084] 201. Detect the temperature of the battery pack.

[0085] In the embodiment of the present invention, for the specific process of detecting the temperature of the battery pack, refer to the description in step 101 in the above embodiment for details. The principle and implementation process are the same in the embodiment of the present invention, and will not be repeated here.

[0086] 202. Compare the temperature of the battery pack with a preset temperature threshold, and if the temperature of the battery pack is greater than the temperature threshold, determine the target temperature of the coolant according to the temperature of the battery pack.

[0087] In the embodiment of the present invention, th...

Embodiment 3

[0099] Figure 5 The first structural schematic diagram of the cooling system of the battery pack provided by the embodiment of the present invention, as shown in Figure 5 As shown, the cooling system of the battery pack in this embodiment may specifically include: a sensor 11 , a battery control system 12 , and a refrigeration control system 13 .

[0100] The sensor 11 is used to detect the temperature of the battery pack, and send the detected temperature of the battery pack to the battery control system 12;

[0101]The battery control system 12 is used to compare the temperature of the battery pack detected by the sensor 11 with a preset temperature threshold, if the temperature of the battery pack is greater than the temperature threshold, determine the target temperature of the coolant according to the temperature of the battery pack, and set The target temperature is sent to the refrigeration control system 13;

[0102] The refrigeration control system 13 is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com