Contactor with low eddy-current loss

A technology of eddy current loss and contactor, which is applied in the field of electric power, can solve the problems of reducing the service life of contactors, noise, vibration, etc., and achieve the effects of reducing noise, reducing eddy current loss, and reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

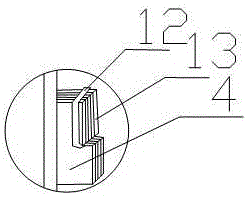

[0019] like Figure 1-2 As shown, the present invention includes a moving contact 1, an inductance coil 2, a rotating rod 3, an iron core 4, a static contact 6, a mounting base 7, a horizontal bar 8 and a base plate 10, the inductance coil 2, the mounting base 7, and The horizontal bar 8 is installed vertically on the bottom plate 10, the inductance coil 2 is located between the mounting seat 7 and the horizontal bar 8, and the iron core 4 is installed on the end face of the inductance coil 2, and the iron core 4 is formed by stacking and riveting a plurality of silicon steel sheets 13. The magnetic ring 12 is installed on the end face of the iron core 4, the static contact 6 is installed on the installation base 7; An armature 5 is also installed on the surface of the armature, and the armature 5 is opposite to the iron core 4, and a terminal 11 is arranged under the rotating rod 3 and on the mounting seat 7; the moving contact 1 is opposite to the static contact 6.

[0020]...

Embodiment 2

[0023] The preferred specific structure of this embodiment is as follows on the basis of Embodiment 1: the iron core 4 is divided into two layers, the two layers are staggered, each layer is riveted together by a plurality of silicon steel sheets 13 vertically stacked, only the top layer is equipped with magnetic ring 12. The two layers are staggered, the magnetic flux of the upper layer and the magnetic flux of the lower layer can work independently without affecting each other, and the upper layer of the core can better realize the magnetic flux passing through the narrow section of the sheet, and the eddy current is limited to some of the sheets. Narrow loops flow through, and the net electromotive force in these loops is small, the length of the loop is large, and because of the high resistivity of this thin sheet material, the eddy current loss can be significantly reduced.

Embodiment 3

[0025] This embodiment adds the following technical features on the basis of the above embodiments: a reaction spring 9 is connected between the bottom of the rotating rod 3 and the bottom of the bottom plate 10 . When the inductance coil is powered off, the iron core and the armature are separated. Due to the pull of the spring, the 360° rotation of the rotating rod is avoided, causing safety accidents, and damaging the moving contact on the rotating rod and the movable connection between the rotating rod and the horizontal bar. , improve the service life. When the iron core and the armature need to be pulled in, the reaction spring can be compressed without affecting the pull-in, which is flexible and convenient to use.

[0026] The opposite ends of the moving contact 1 and the static contact 6 are arc-shaped.

[0027] The angle range that the rotating rod 3 can rotate counterclockwise around the movable connection point on the horizontal bar 8 is 0-45°. While ensuring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com