CNC processing smooth transition method and device

A smooth transition and transition arc technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve problems such as expensive, not open to the outside world, inconvenient to use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

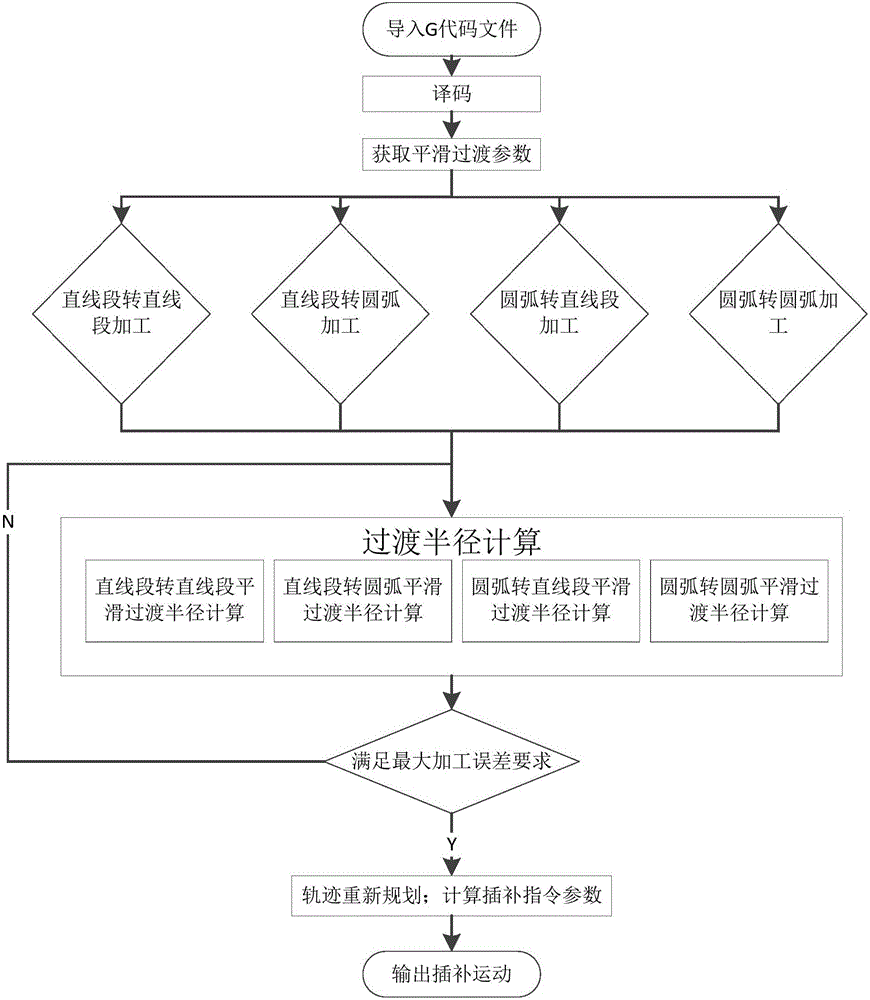

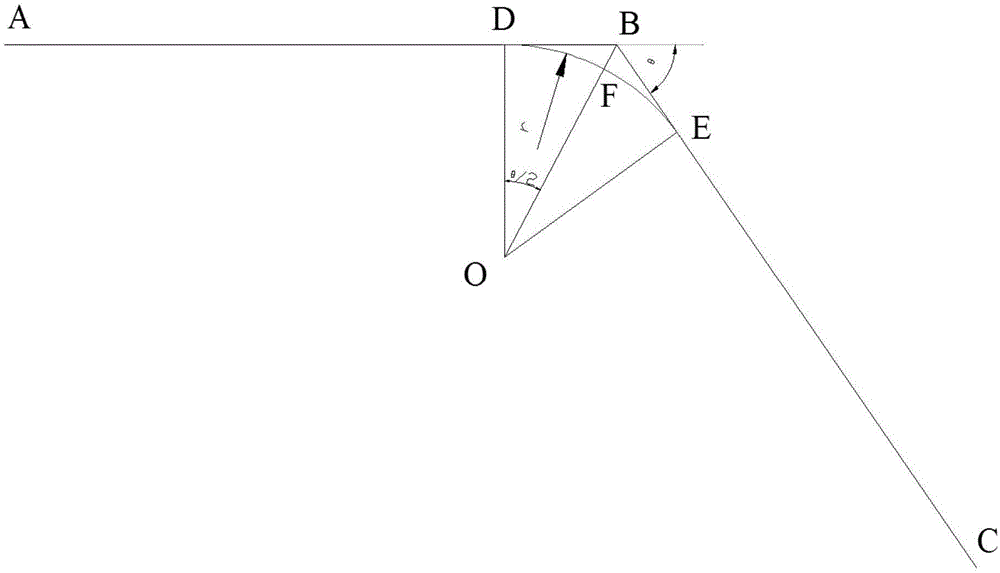

[0062] Please combine figure 2 , when processing the straight line segment AB to the straight line segment BC, the smooth transition method includes the following steps.

[0063] Step 1, acquisition of smooth transition parameters. The starting point A coordinate of the straight line segment AB, the turning point B coordinate, and the end point C coordinate of the straight line segment BC are used as the smooth transition parameters for the straight line segment AB to straight line segment BC processing;

[0064] Step 2, obtaining the radius of the target transition arc segment.

[0065] First, according to the vector of the straight line segment AB and the vector of the straight line segment BC, the vector angle θ is obtained, and at the same time, the rotation direction of the transitional arc segment DE is obtained according to the cross product of the vector of the straight line segment AB and the vector of the straight line segment BC; then according to the preset Set ...

Embodiment 2

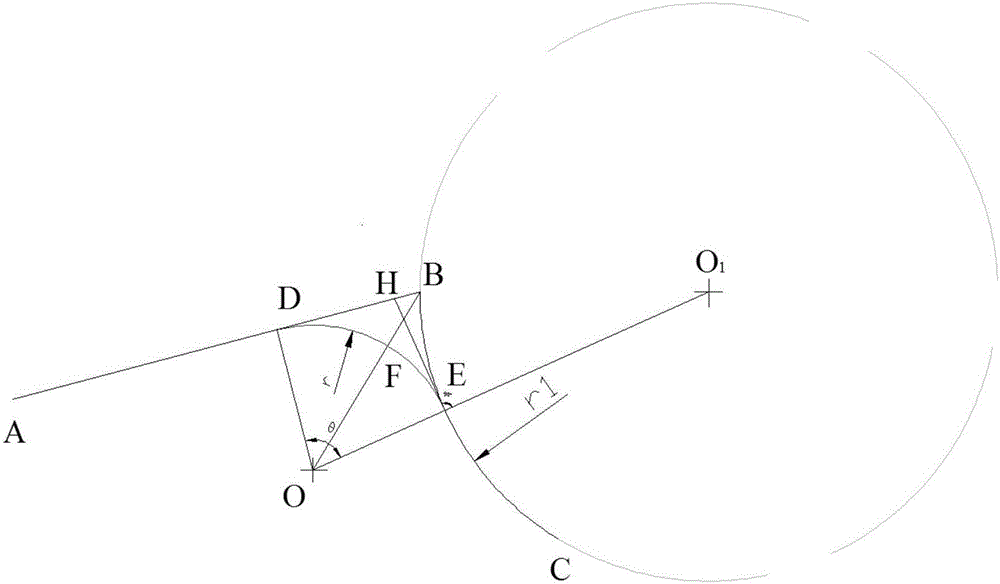

[0085] Please combine image 3 , when performing straight line segment AB to arc segment BC processing, or arc segment CB to straight line segment BA processing, the smooth transition method includes the following steps:

[0086] Step 1. Acquisition of smooth transition parameters: the coordinates of the starting point A of the straight line segment AB, the coordinates of the turning point B, the coordinates of the end point C of the arc segment BC, and the radius r 1 and the center coordinate O 1, the rotation direction of the arc segment BC is used as the smooth transition parameter for the machining of the straight line segment AB to the arc segment BC, or the rotation direction of the arc segment CB is used as the smooth transition parameter for the machining of the arc segment CB to the straight line segment BA;

[0087] Step 2. Acquisition of the radius of the target transition arc segment: first, according to the preset arc radius r, combined with the tangent equation ...

Embodiment 3

[0096] Please combine Figure 4 , when performing arc segment AB to arc segment BC processing, the smooth transition method includes the following steps:

[0097] Step 1. Acquisition of smooth transition parameters: set the coordinates of the starting point A of the arc segment AB, the radius r 1 and center O 1 Coordinates, turning point B coordinates, end point C coordinates of arc segment BC, radius r 2 and center O 2 The coordinates, the rotation direction of the arc segment AB and the rotation direction of the arc segment BC are used as the smooth transition parameters for the processing of the arc segment AB to the arc segment BC;

[0098] Step 2: First, according to the preset radius r of the arc, combined with the tangent equations of the arc segment AB and the arc segment BC, the point D can be found on the arc segment AB and the point E can be found on the arc segment BC respectively. The tangent line intersects at point H, such as figure 2 As shown, the arc tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com