Grips for creating stress in tubular test pieces

A test piece and tubular technology, which is applied in the field of stress corrosion test tooling for pipeline connectors, can solve the problems of parallel pipeline components, inconsistent specifications of pipeline components, and difficulty in uniform arrangement, achieving low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] As an example, the clamp for generating stress in a tubular test piece according to the present invention can be applied to stress corrosion of piping pieces or related products in the fields of weapons, electronics, rail transportation and the like.

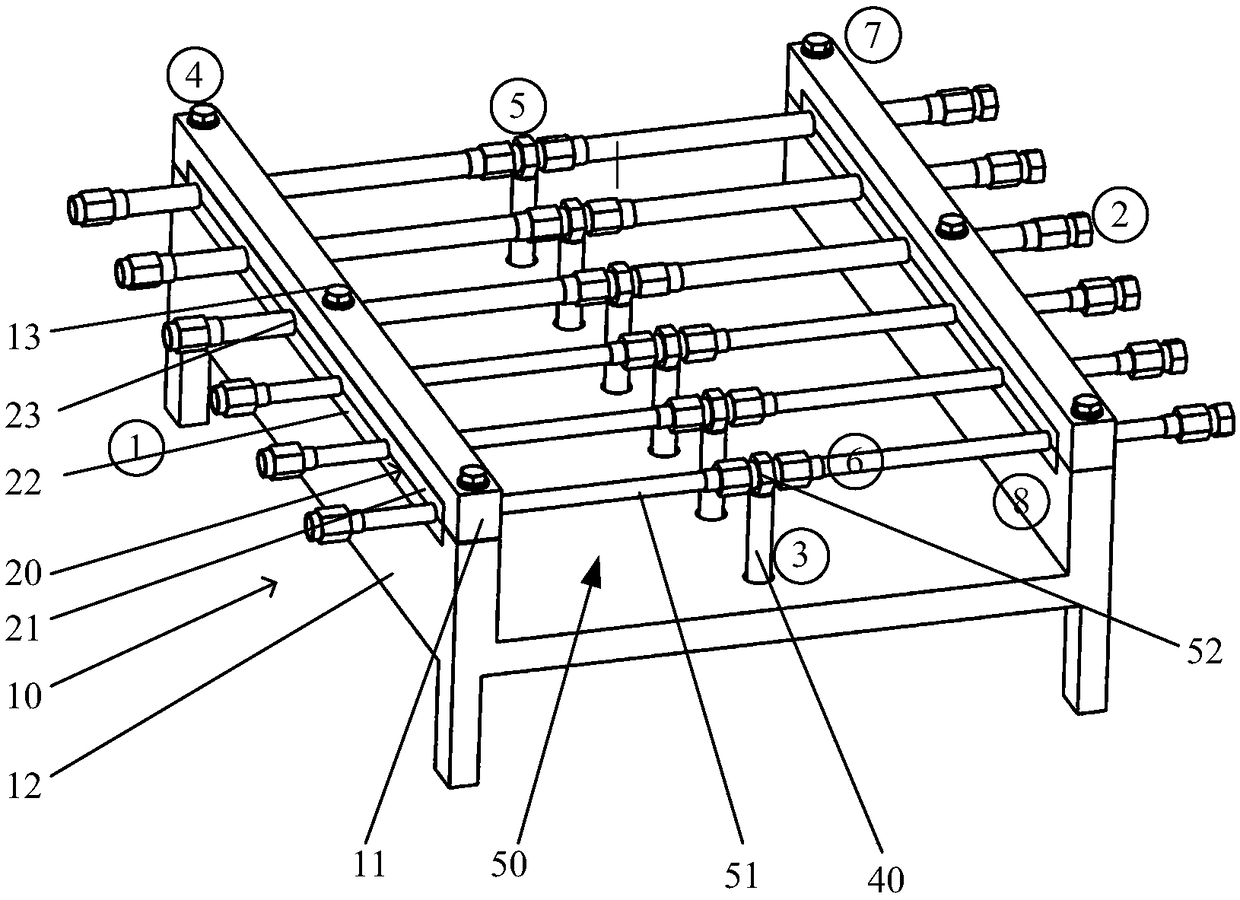

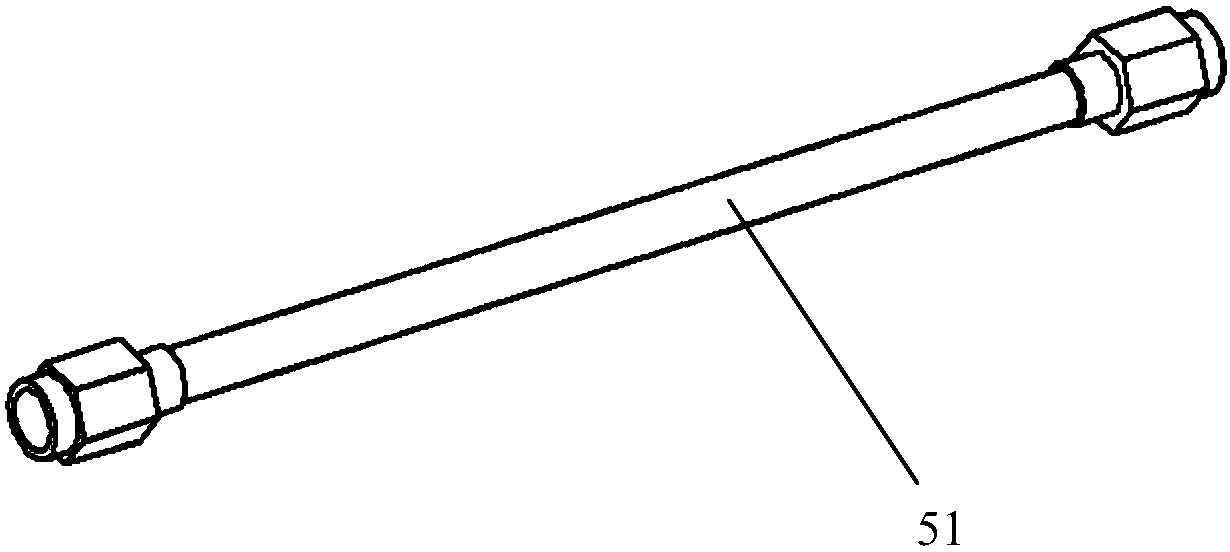

[0034] Such as figure 1 As shown, the clamp for generating stress in a tubular test piece according to the present invention includes a main body 10 , a pair of spaced apart clamping members 20 , and a force applying member 40 . The clips 20 are received respectively in both ends of the main body 10 to be fixed. Both sides of the tubular test piece 50 are clamped by the clamping piece 20 and fixed in the fixture. The force applying member 40 applies force to the tubular test piece 50 to generate stress in the tubular test piece 50 .

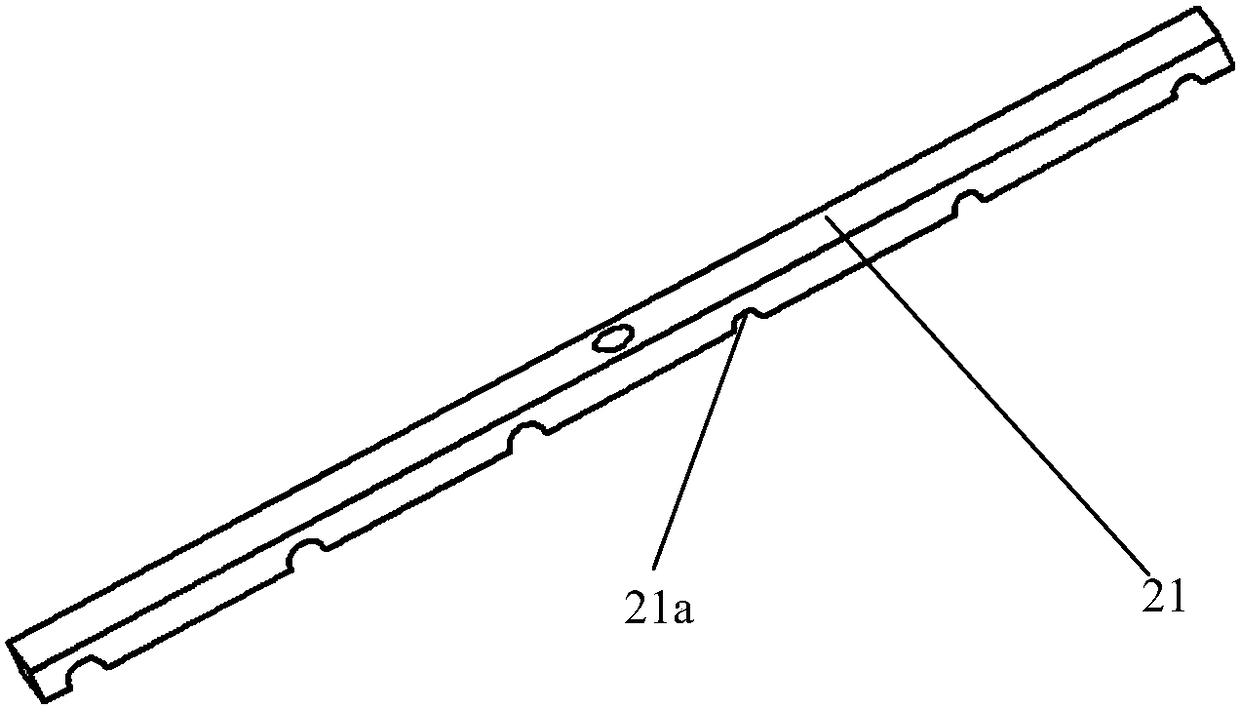

[0035] Such as image 3 and 4 as shown, figure 1 Each cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com