Deep sea led lighting

A kind of LED lighting, deep-sea technology, applied in the direction of lighting devices, fixed lighting devices, lighting and heating equipment, etc., to achieve the effect of enhancing compression resistance, relieving pressure changes, and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

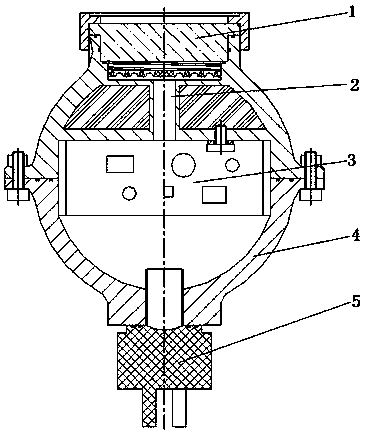

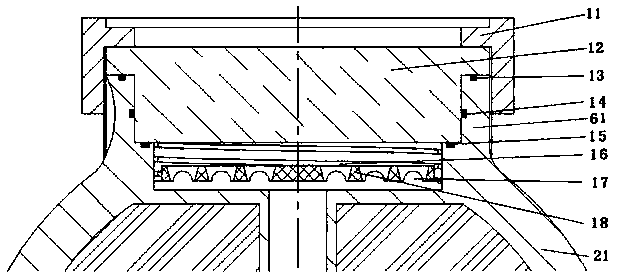

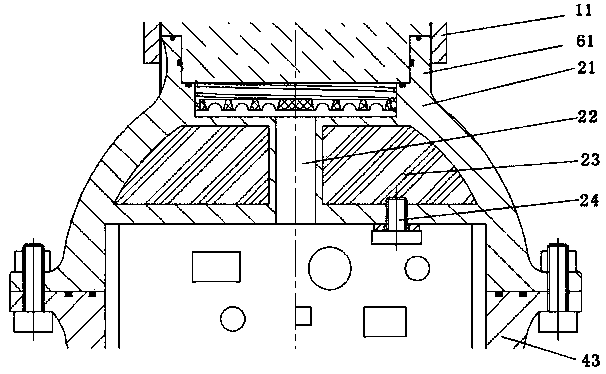

[0034] In this example, see Figure 1-7, a deep-sea LED lighting lamp, composed of a lamp head 1, a lamp front 2, a lamp middle 3, a lamp rear 4 and a watertight connector part 5; the shell part of the lamp front 2 and the lamp housing of the lamp rear 4 Parts are all hemispherical, the shell part of the lamp front part 2 is used as the front lamp housing 21, and the lamp housing part of the lamp rear part 4 is used as the rear lamp housing 43, and the front lamp housing 21 and the rear lamp housing 43 are sealed and connected together to form a spherical lighting The lamp spherical shell, the front lamp housing 21 and the rear lamp housing 43 form an internal chamber mainly composed of the front sealed cavity 63 and the rear driver assembly cavity. The front sealed cavity 63 is mainly located at the front of the lamp front 2, and the rear A part of the front driver assembly cavity is mainly located at the rear of the lamp front 2, and another part of the rear driver assembly ...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this embodiment, in the middle part 3 of the lamp, the continuous shell inner surface formed by connecting the front lamp housing 21 and the rear lamp housing 43 forms the inner wall surface of the middle part 3 of the lamp, and the circuit board of the driving circuit part 31 is in an arc-shaped curved surface, so that the driving The circuit board of the circuit part 31 is closely mounted on the inner wall of the lamp middle part 3, so that the inner wall of the lamp middle part 3 forms a thermal bridge structure between the circuit board of the driving circuit part 31 and the seawater environment medium outside the overall shell of the LED lighting lamp. The hot end surface of the heat dissipation part of the power supply assembly is also closely attached to the inner wall of the lamp middle part 3, so that the inner wall surface of the lamp middle part 3 forms the heat between the ...

Embodiment 3

[0046] This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this embodiment, the front lamp housing 21 and the rear lamp housing 43 are tightly connected by screw fit connection fastening and sealing ring sealing. In this embodiment, the front lamp housing 21 and the rear lamp housing 43 are fastened by screw fit, which is convenient for quick disassembly and assembly, takes advantage of modular assembly, reduces the cost of assembly production and maintenance, and improves the efficiency of assembly production and maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com